Workpiece positioning device

A technology for positioning devices and workpieces, which is applied to positioning devices, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of complex clamping state switching and affecting clamping accuracy, and achieves a simple and reliable fixing method, low cost and easy to implement. The effect of production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following, the present invention will be further described in conjunction with the specific embodiments of the accompanying drawings.

[0027] It should be noted that, on the premise of no conflict, the various embodiments or technical features described below can be combined arbitrarily to form new embodiments.

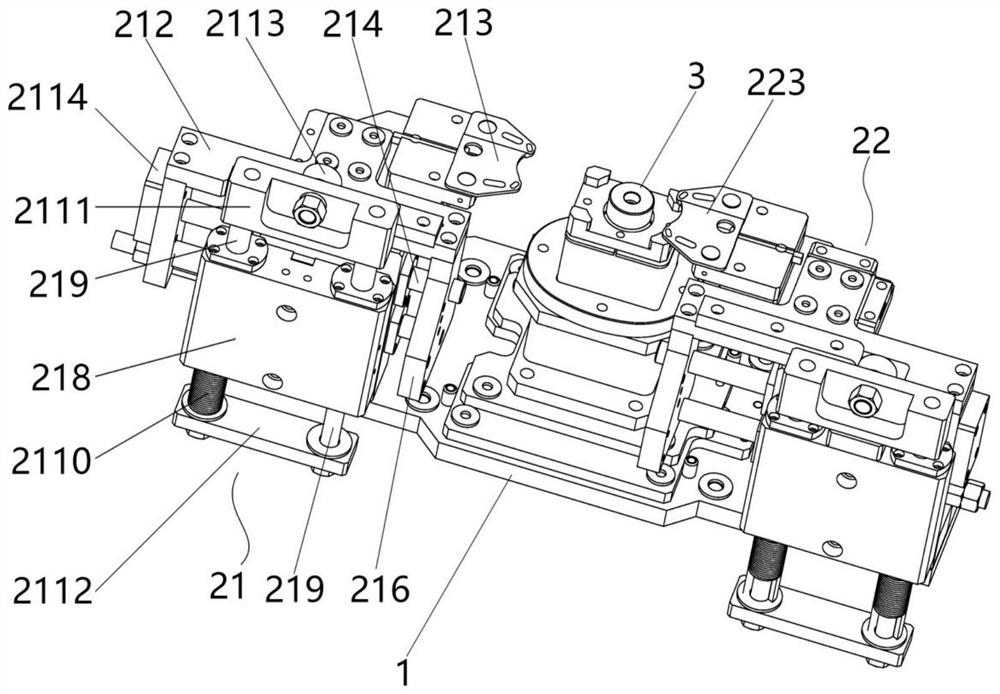

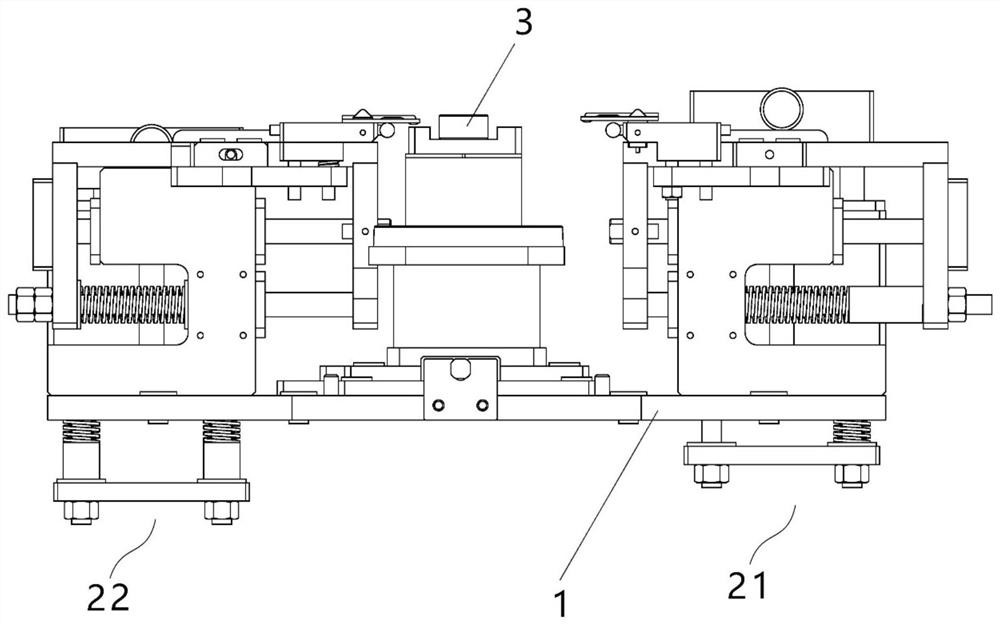

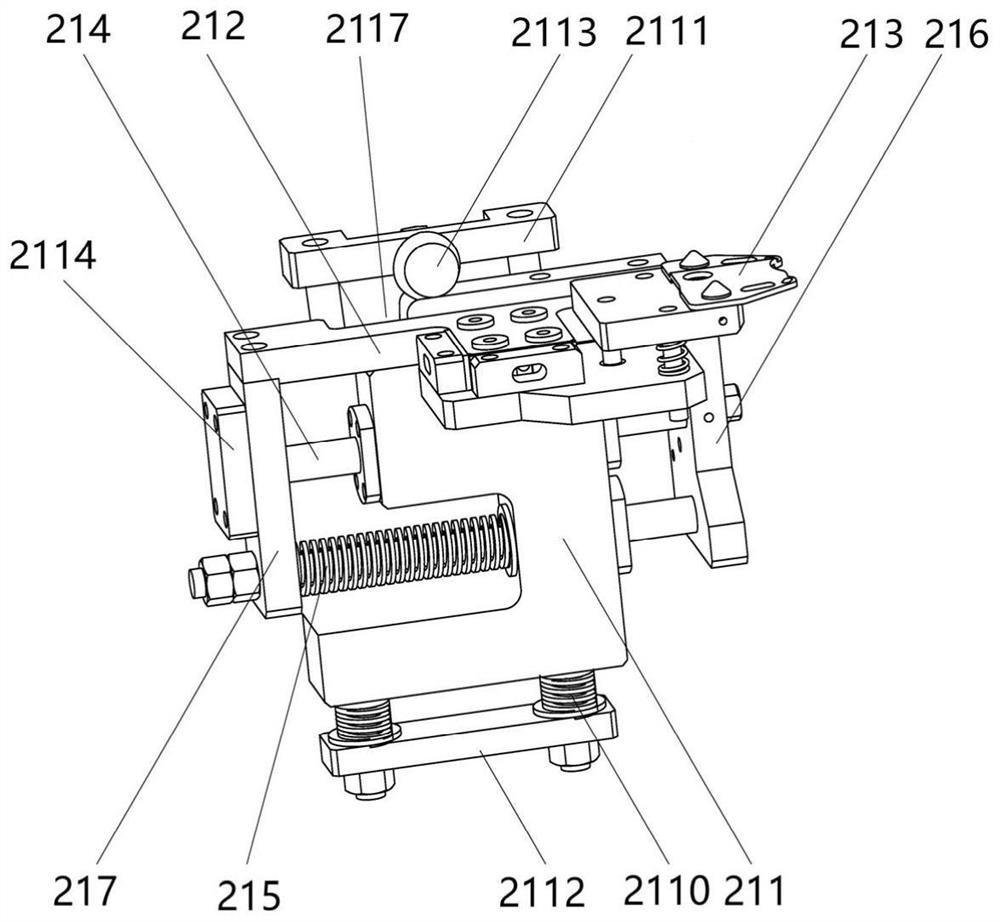

[0028] A workpiece positioning device, comprising at least one fixing assembly, which is arranged close to the positioning position of the workpiece, characterized in that: the fixing assembly includes a clamp, a fixing seat 211, an up and down moving assembly, and a left and right moving assembly;

[0029] The left and right moving components include a left and right moving component fixing block 212, a left and right guide rod 214, and a first spring 215. The first spring 215 is sleeved on the left and right guide rod 214, and one end of the first spring 215 is fixed on the left and right Guide rod 214, the other end is fixed on described fixed seat 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com