Natural caving method based safe ore drawing control method

A technology of natural caving method and ore drawing pipe, which is applied in mining equipment, surface mining, mining equipment, etc., can solve the problems of affecting the economic benefits of natural caving method, loss and dilution, and large deviation of ore volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

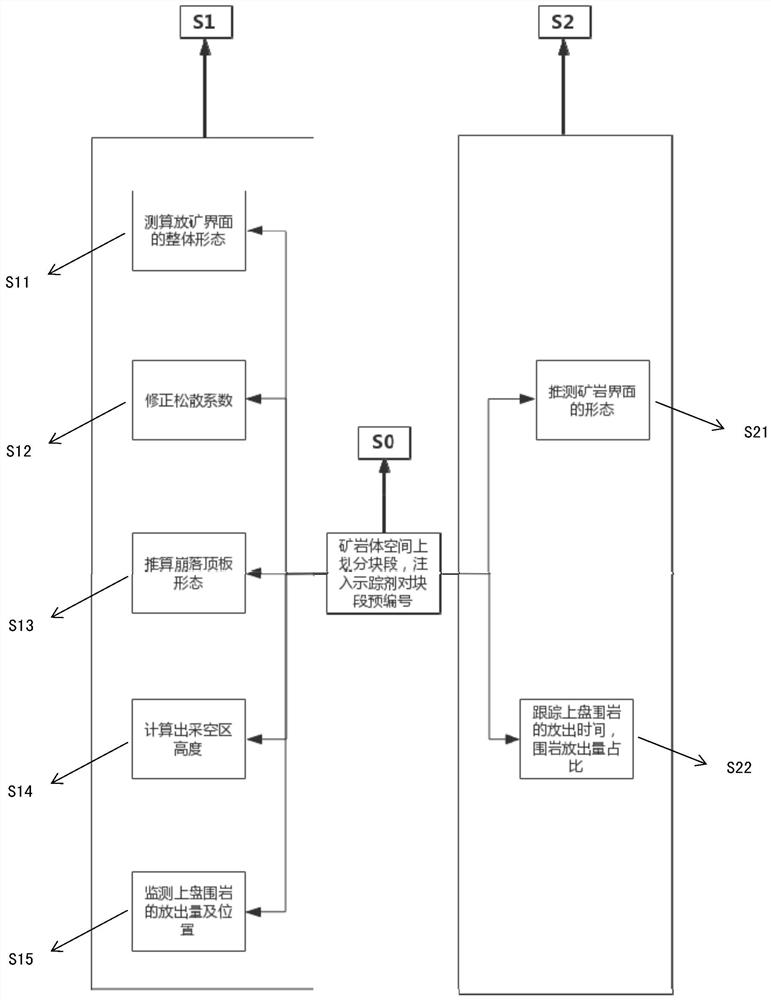

[0021] Such as figure 1 As shown, a kind of natural caving method safety ore drawing control method natural caving method safety ore drawing control method natural caving method safety ore drawing control method natural caving method safety ore drawing control method proposed by the present invention, it comprises the first stage (S1) of natural caving method ore drawing and natural The second stage (S2) of ore drawing by the caving method also includes firstly dividing the ore-rock space into blocks, and then proceeding according to the following steps and conditions:

[0022] A. Inject the tracer to pre-number the blocks (S0). First, according to the distribution of the ore body and surrounding rock, divide them into multiple segments in the vertical direction, and number the divided blocks according to the spatial position. The specification and size of the blocks shall be determined according to the artificial fracturing technology adopted;

[0023] B. In the first stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com