Automated bun handling system for handling different types and numbers of buns in accordance with patron orders

A pastry, order technology, applied in the field of automatic pastry processing and baking systems, can solve the problems of time-consuming labor, inefficiency, and intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

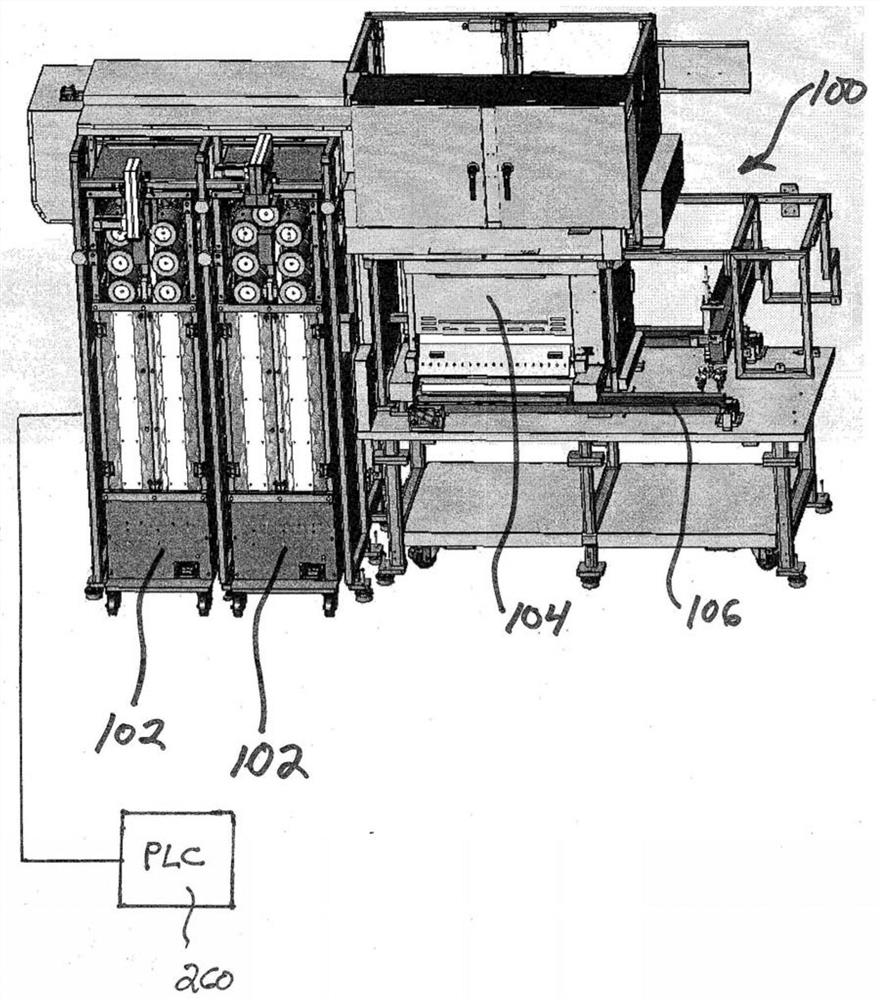

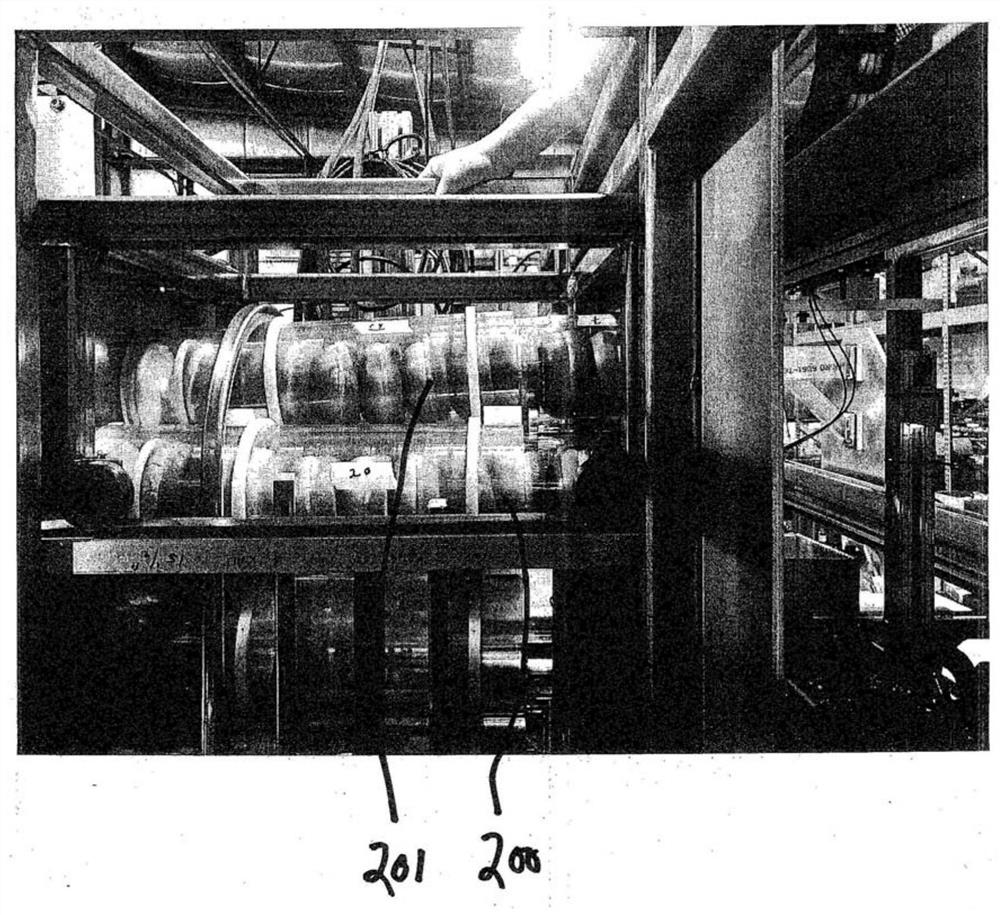

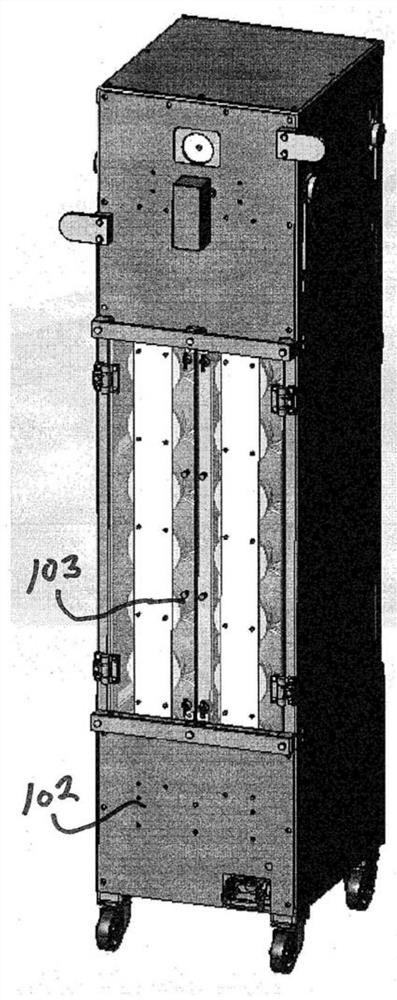

[0035] Referring now to the drawings, and more particularly to the figure 1 , discloses a new and improved automatic pastry feeding and baking system constructed in accordance with the principles and teachings of the present invention and generally designated by the reference numeral 100 . More specifically, it can be seen that the new and improved automated pastry feeding and baking system 100 includes a pair of pastry storage cabinets for housing many or more pastry storage tubes as will be described more fully hereinafter. 102. Bakeware 104, and conveyor mechanism 106 for delivering pastry to a pastry pick-up station where the pastry will be further processed for sandwich order making, packaging of completed food items, etc. . Of course, it should be noted that system 100 may include more than two pastry storage cabinets 102, as may be deemed desirable or necessary for the efficient operation of the particular food establishment within which system 100 is used.

[0036] n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com