Pharmaceutical mixing machine with automatic feeding mechanism

An automatic feeding and mixer technology, applied in mixers, shaking/vibrating/vibrating mixers, mixer accessories, etc., can solve the problems that the mixing effect cannot meet the production needs, and the large particle powder cannot be effectively pulverized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

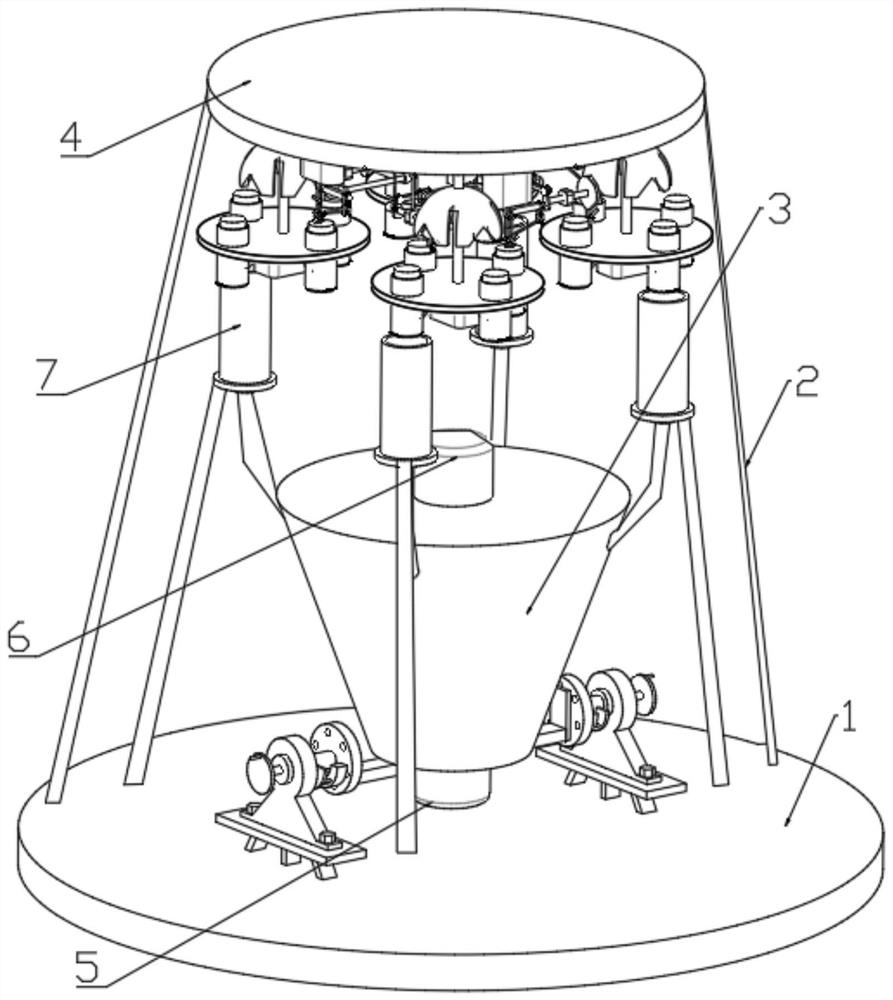

[0030] see Figure 1-6 , in an embodiment of the present invention, a pharmaceutical mixer with an automatic feeding mechanism mainly includes a lower bottom plate 1 .

[0031] The upper side of the lower bottom plate 1 is symmetrically provided with a plurality of support rods 2 and fixing mechanisms, the other end of the support rods 2 is provided with an upper top plate 4, and the lower side of the upper top plate 4 is provided with a powder spreading mechanism.

[0032] The fixing mechanism includes a plurality of fixing frames, the upper side of the fixing frame is provided with a fixing plate 25 through fixing bolts, and the opposite sides of two adjacent fixing plates 25 are provided with rotating shafts, and the rotating shafts are provided with Fixed block 29 and limit block 28, described fixed block 29 is provided with limit bar near the side of limit block 28, and described limit block 28 is provided with limit bar that can be connected with limit bar near the side ...

Embodiment 2

[0036] On the basis of the pharmaceutical mixer with automatic feeding mechanism described in embodiment 1, the differences between this embodiment and embodiment 1 are:

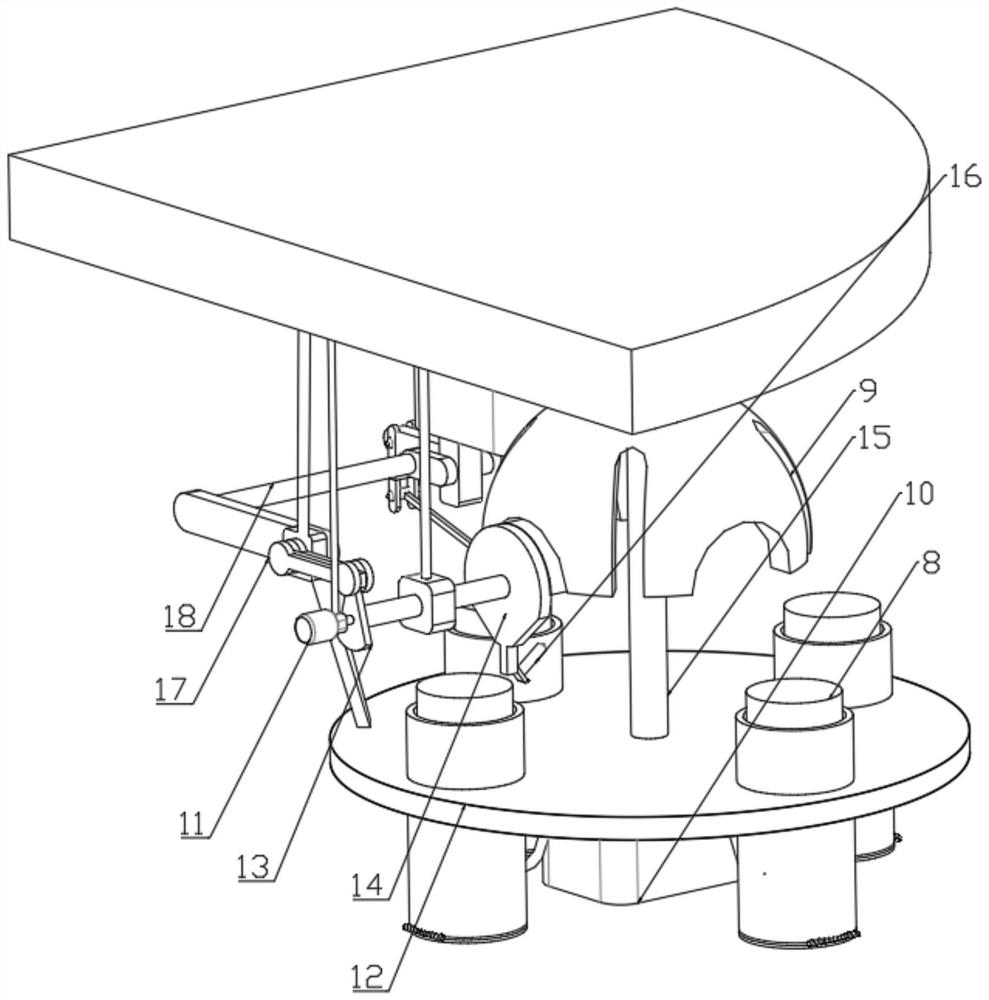

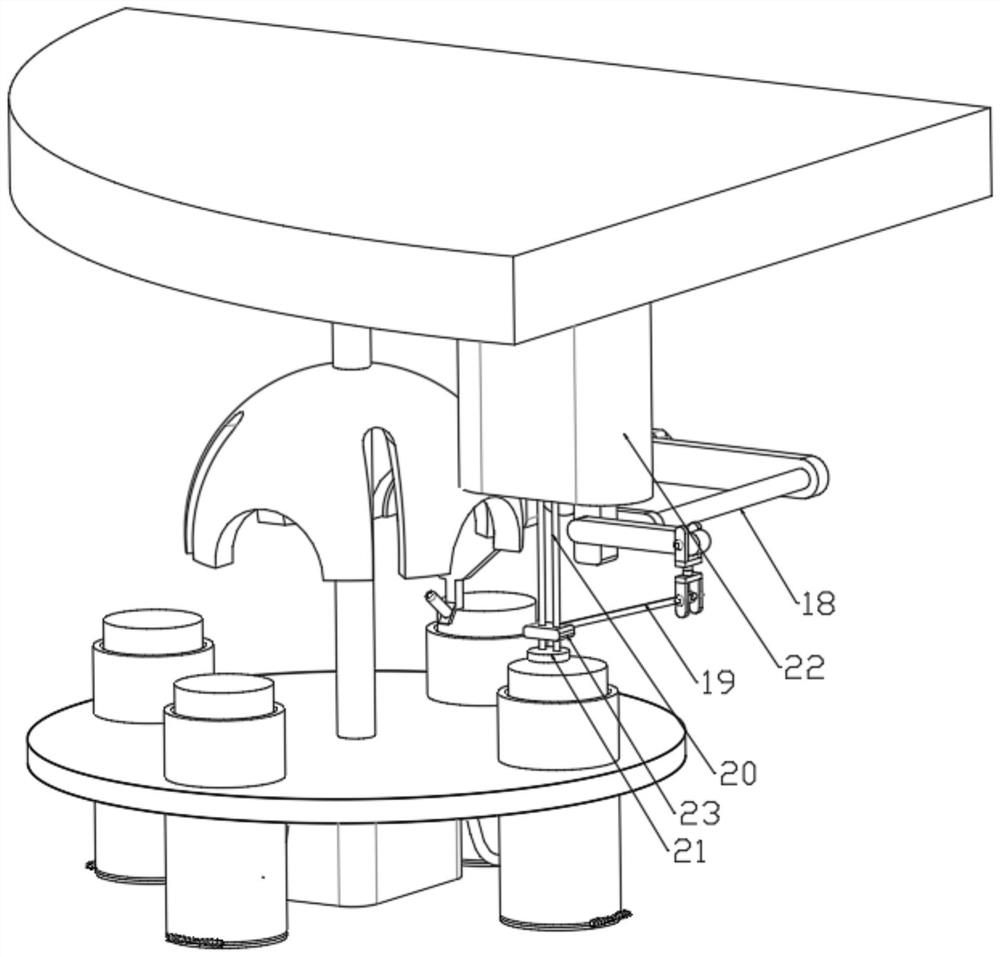

[0037] In this embodiment, the powder spreading mechanism includes a central rod 15 and a No. 2 motor 11, the upper end of the central rod 15 is rotatably arranged on the lower side of the upper top plate 4, and the central rod 15 is provided with a receiving ring 9 , the receiving ring 9 is provided with a circular groove and a vertical groove, the other end of the central rod 15 is provided with a turntable 12, and the turntable 12 is provided with a plurality of installation cylinders, which slide up and down to insert Connected with connecting cylinder 8.

[0038] The output end of the No. 2 motor 11 is connected with a mounting block, and the mounting block is fixed on the upper side of the upper top plate 4 through a fixed rod. The output end of the No. 2 motor 11 is connected with a rocker 13, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com