Universal robot capable of self-adaptively crossing steps

An adaptive and robotic technology, applied in the field of universal robots, can solve problems such as the inability to effectively cross and walk ladder-shaped obstacles, and achieve high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

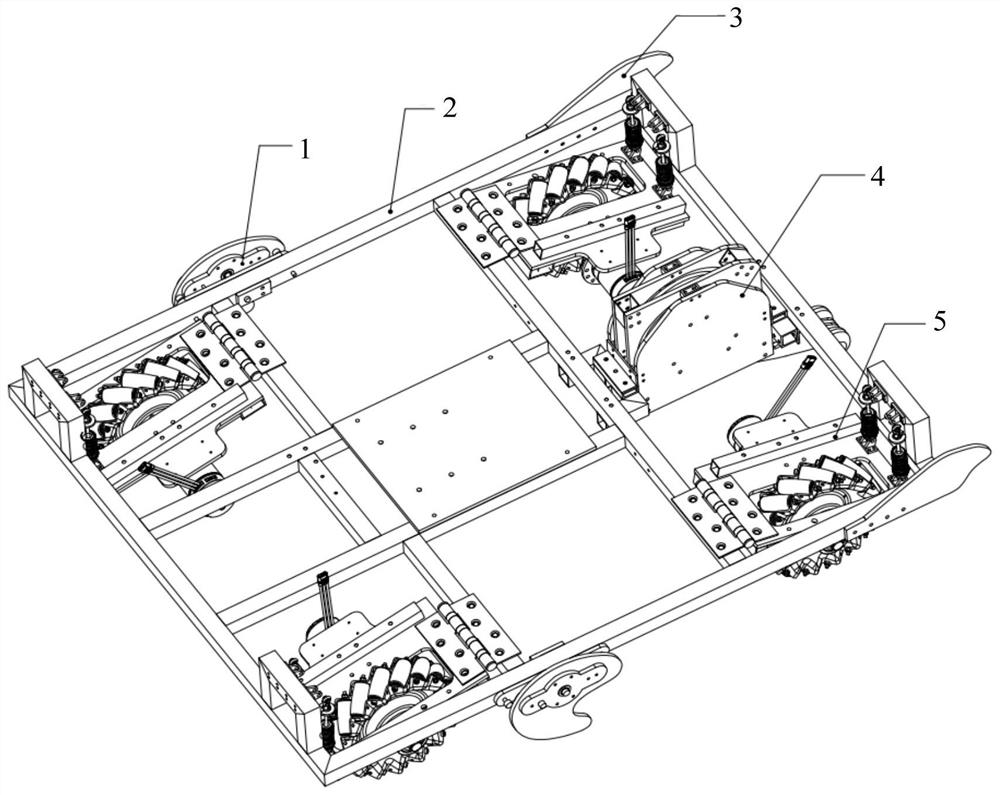

[0058] Specific implementation mode one: the following combination Figure 1-Figure 5Describe this embodiment mode, a universal robot that self-adaptively straddles the stairs described in this embodiment mode, it includes a rotating cam 1, a frame 2, a straightening plate 3, a pole vault mechanism 4 and a running mechanism 5;

[0059] The four traveling mechanisms 5 are installed on the four corners of the frame 2 respectively, and the two rotating cams 1 are installed on the sides of the frame 2 respectively, and are respectively located at the front ends of the two traveling mechanisms 5 at the rear, and the two righting plates 3 are installed on the frame 2, and are respectively located on the side of the two front running mechanisms 5, the pole vault mechanism 4 is installed inside the frame 2, and placed between the two front running mechanisms 5;

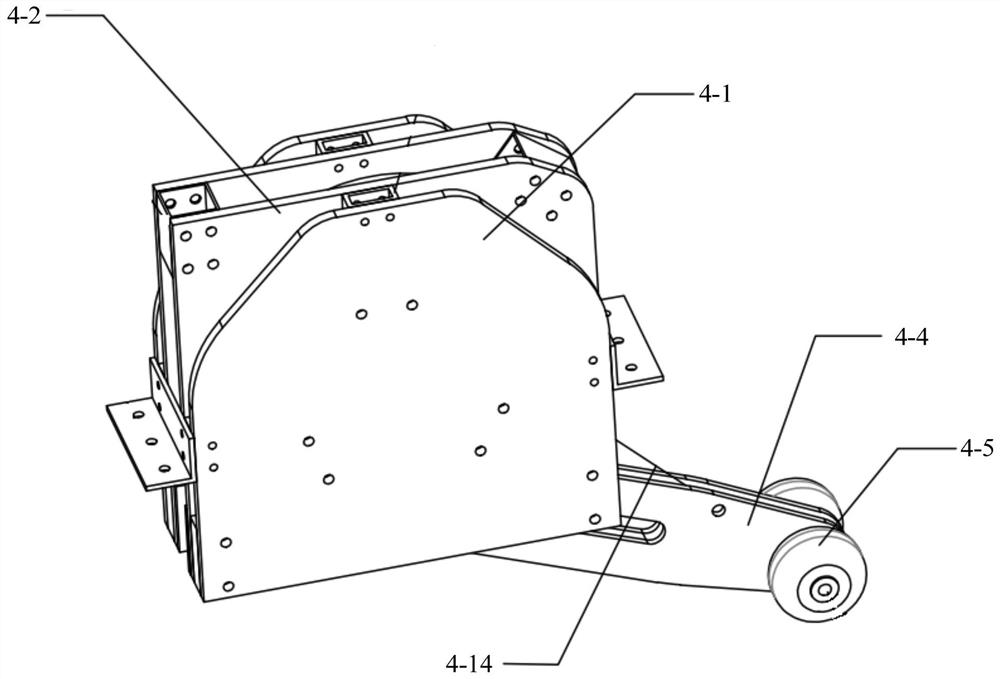

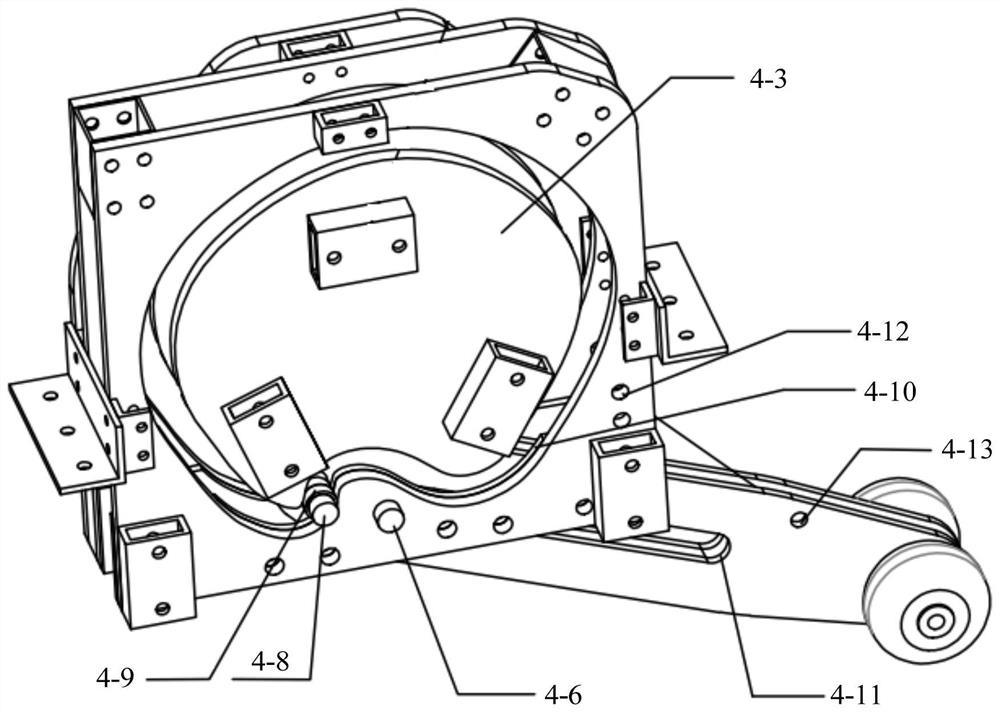

[0060] The pole vault mechanism 4 includes two fixed plates 4-1, two track outer plates 4-2, two track inner plates 4-3, su...

specific Embodiment approach 2

[0074] Specific implementation mode two: the following combination Figure 6-Figure 8 Describe this embodiment, this embodiment will further describe the first embodiment, the rotary cam 1 includes a cam plate 1-1, a first reinforcement plate 1-3, a second reinforcement plate 1-4, and a third reinforcement plate 1-5 and the fourth reinforcing plate 1-6;

[0075] The cam plate 1-1 is a "C" type structure, and the two sides of the cam plate 1-1 are respectively provided with a first reinforcing plate 1-3 and a second reinforcing plate 1-4, and the third bolt 1-2 passes through the first Reinforcement plate 1-3, cam plate 1-1, second reinforcement plate 1-4, third reinforcement plate 1-5, frame 2 and fourth reinforcement plate 1-6 are then screwed with nuts so that cam plate 1- 1 can freely rotate around the third bolt 1-2;

[0076] A fourth bolt 1-9 is arranged on the side of the cam plate 1-1 facing the frame 2, a fifth bolt 1-10 is arranged on the frame 2, and an elastic pul...

specific Embodiment approach 3

[0079] Specific implementation mode three: the following combination Image 6 with Figure 7 This embodiment will be described. This embodiment will further describe the second embodiment. The rotary cam 1 also includes a first flange bearing 1-7 and a second flange bearing 1-8.

[0080] The third bolt 1-2 passes through the first flange bearing 1-7, the first reinforcement plate 1-3, the cam plate 1-1, the second reinforcement plate 1-4, the second flange bearing 1-8, the Three reinforcing plates 1-5, a frame 2 and a fourth reinforcing plate 1-6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com