rolling bearing

A technology for rolling bearings and rollers, applied in the field of rolling bearings, can solve the problem of uneven distribution of grease, and achieve the effects of uniform distribution of grease, reduced service life, and improved friction loss of rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

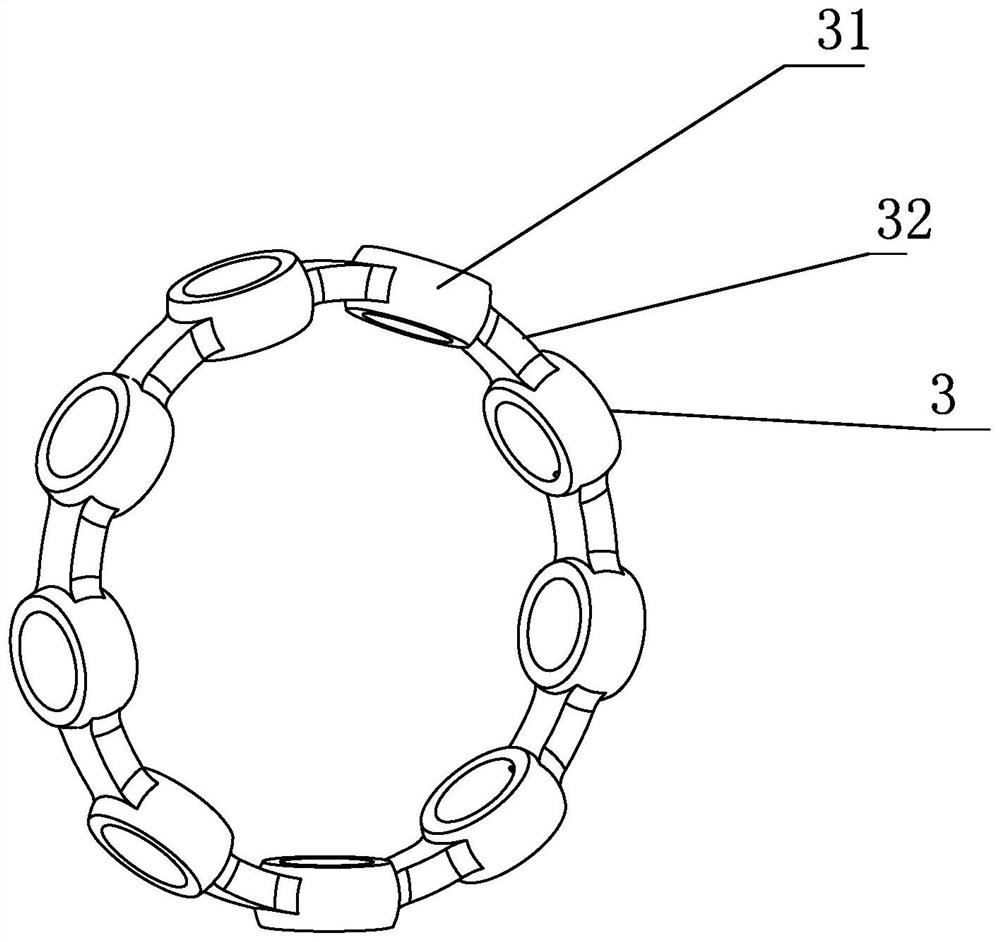

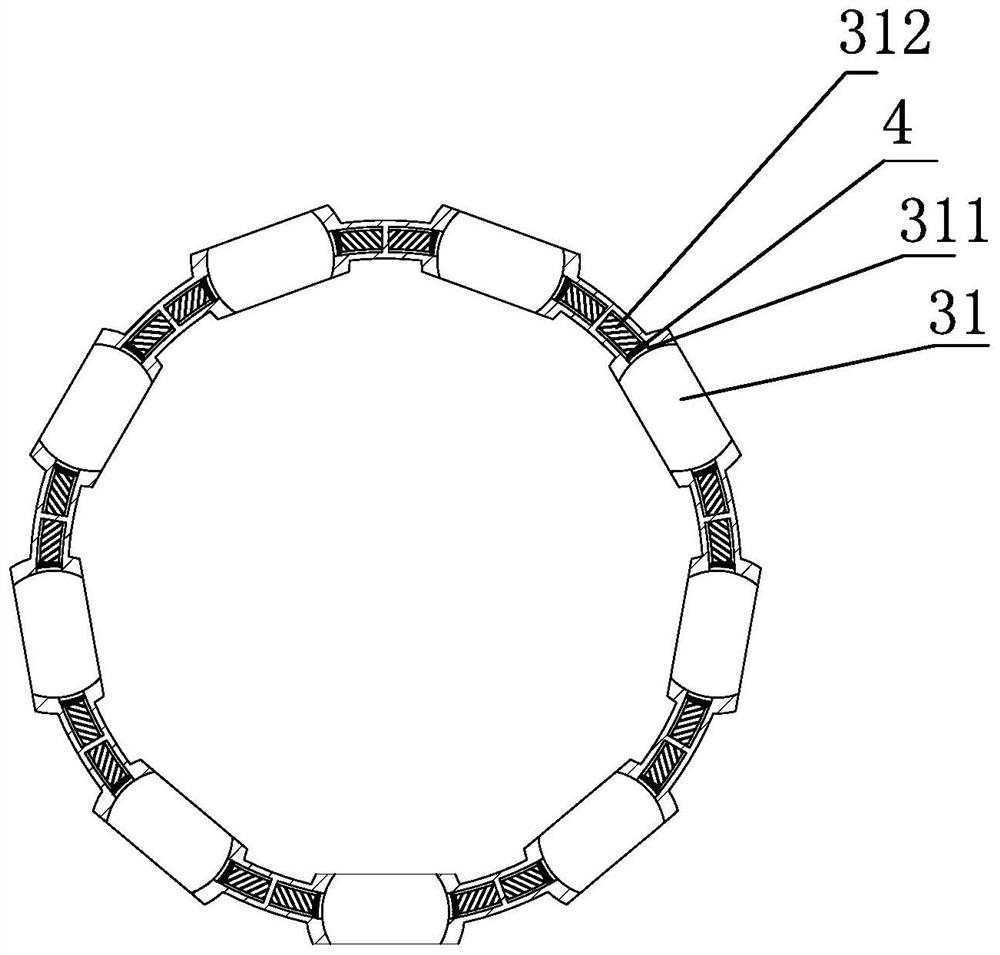

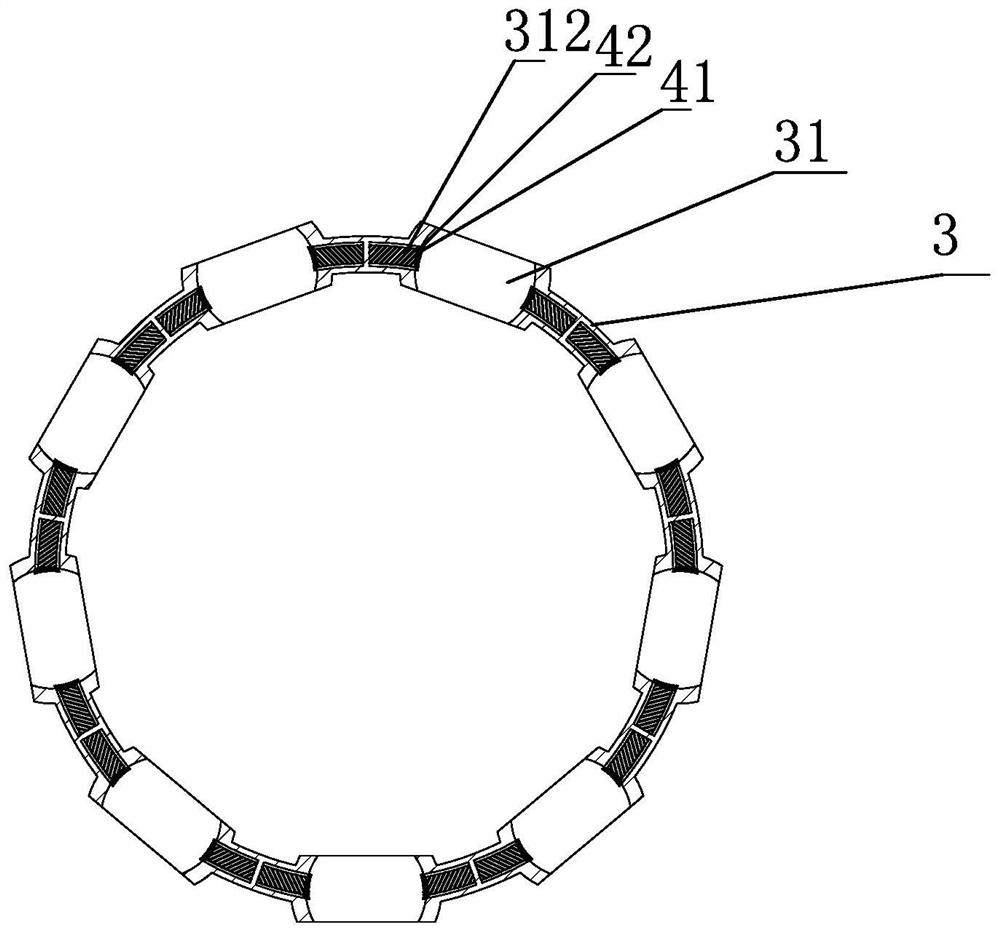

[0024] The present invention provides a rolling bearing, which includes an inner ring 1, an outer ring 2 and a cage 3. The cage 3 is provided with several pockets 31 for accommodating rollers. body 32, the inner wall of the pocket hole 31 is provided with a slot 311, the slot 311 is provided with a movable block 312, one end of the movable block 312 is fixedly connected with the inner wall of the slot 311, and the other end is provided with a grease scraping cotton 4. The movable block 312 is made of a shape memory alloy, the movable block 312 has a first shape at a first temperature, and the movable block 312 has a second shape at a second temperature, and the movable block 312 has a second shape at a second temperature. Stretching in the first form makes the grease scraping cotton 4 expose the slot 311 and contacts the inner roller of the pocket hole 31, and the movable block 312 shrinks in the second shape so that the grease scraping cotton 4 retracts into the slot 311, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com