Adjusting method and adjusting device of methanol synthesis system

A technology of methanol synthesis and adjustment method, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problems of severe reaction of the second reaction, large bypass gas volume, and low inlet temperature of the second reaction, and achieves the guarantee The effect of reaction yield, improvement of overall life, and increase of secondary anti-load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

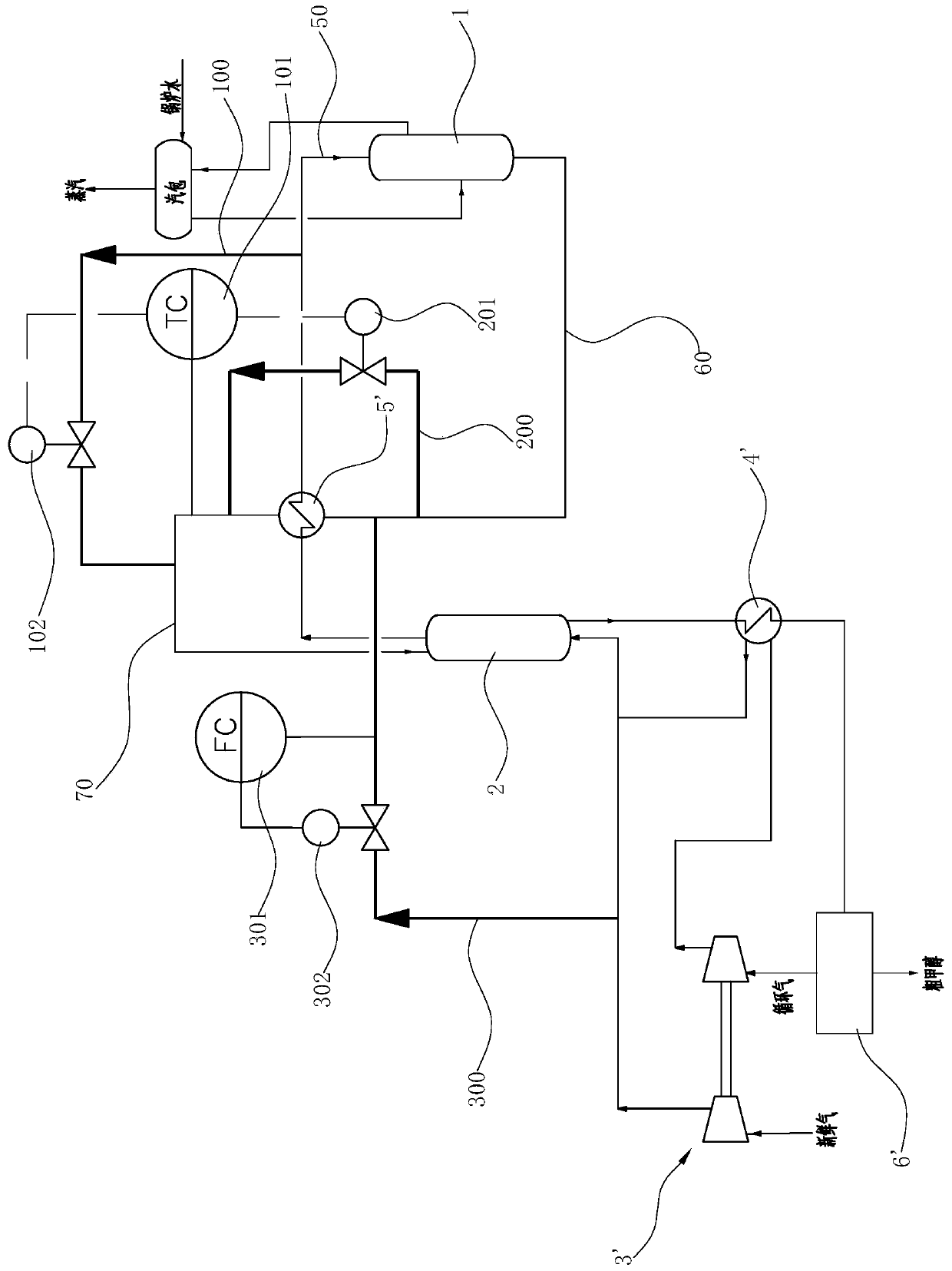

[0028] The adjustment method of the methanol synthesis system in this embodiment is applicable to both the water-cooled-water-cooled methanol synthesis system and the air-cooled-water-cooled methanol synthesis system.

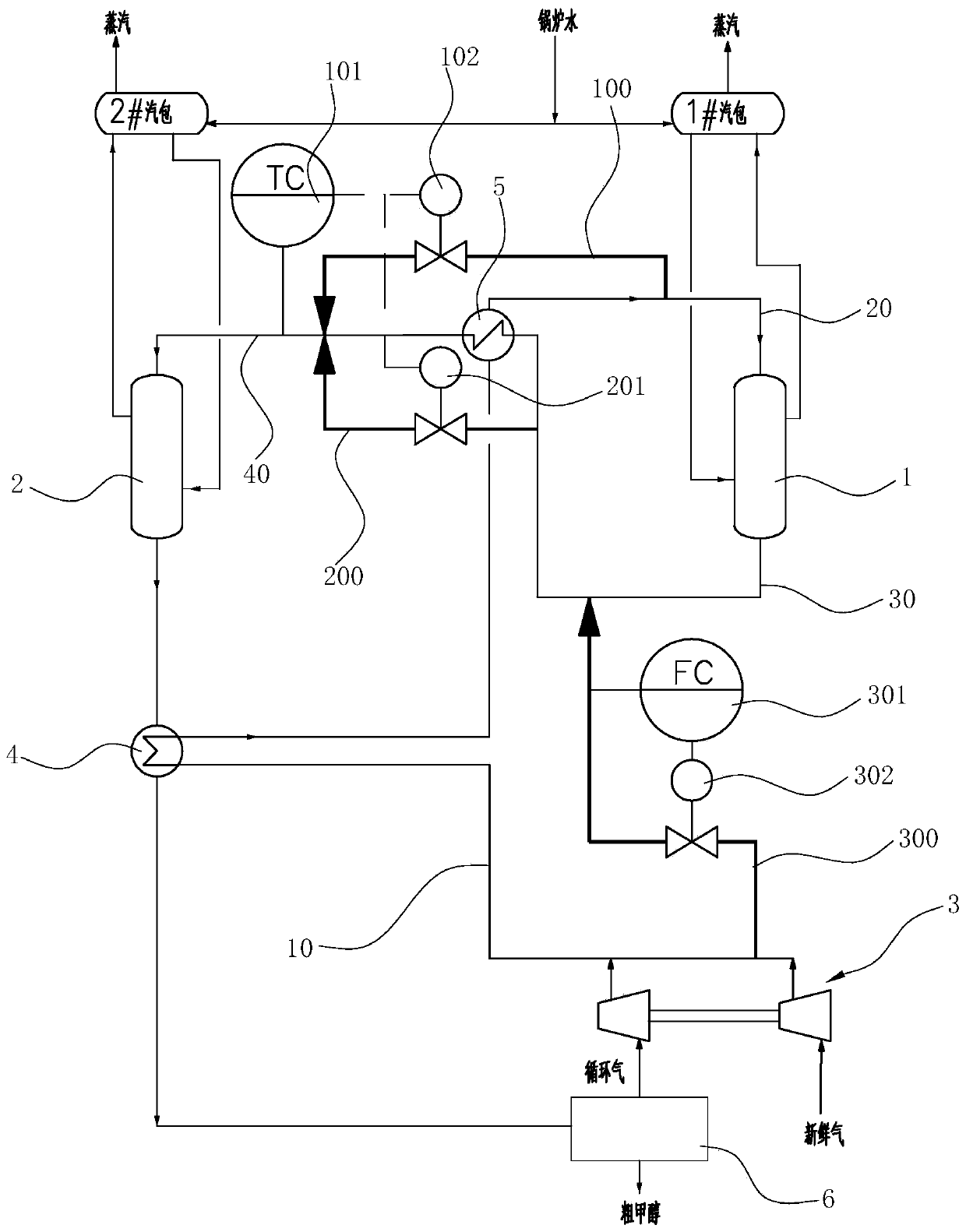

[0029] Such as figure 1As shown, the adjustment device of the water-cooled methanol synthesis system in this embodiment includes a primary methanol synthesis reactor 1, a secondary methanol synthesis reactor 2, a first compression system 3, a first synthesis gas heat exchanger 4, a first Between the interstage heat exchanger 5 and the first methanol separation cooling system 6, the inlet of the primary methanol synthesis reactor 1 and the inlet of the secondary methanol synthesis reactor 2 are connected with a first regulating pipeline 100, and the first regulating The pipeline 100 is provided with a temperature detector 101 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com