A support for fast and precise positioning of truss nodes in truss bridges

A technology for precise positioning and truss bridges, which is applied in the direction of erecting/assembling bridges, bridges, and bridge construction. It can solve problems such as insufficient research on support design, and achieve the effects of easy installation and disassembly, reduced wear, and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structure of the present invention will be further described below in conjunction with the accompanying drawings and examples. It should be noted that this embodiment is illustrative rather than limiting.

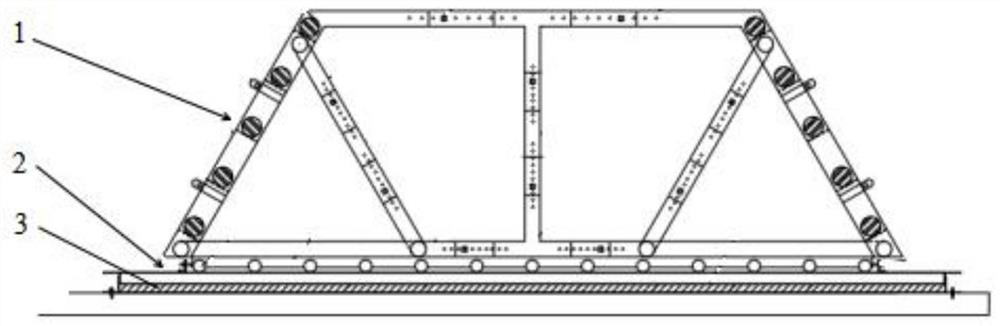

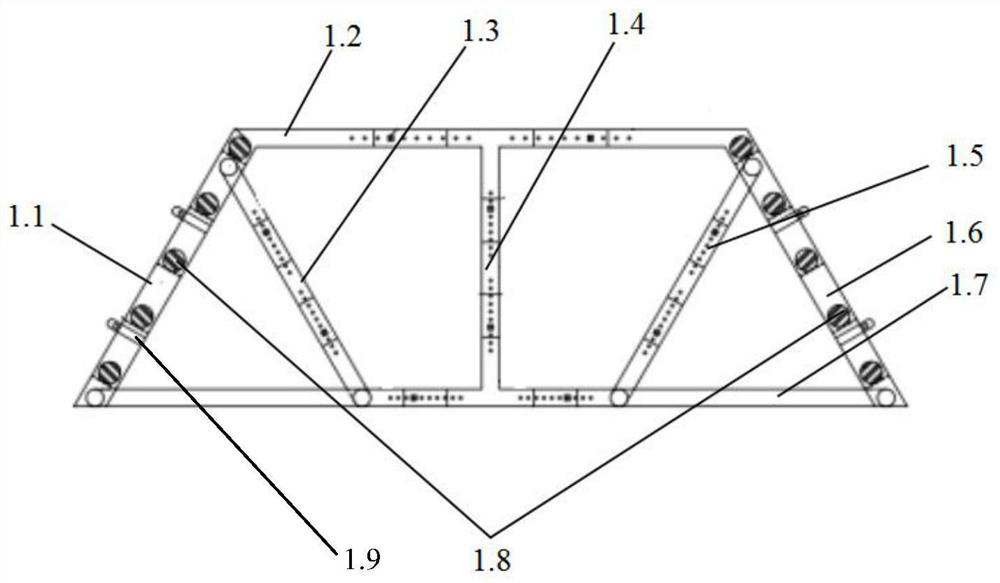

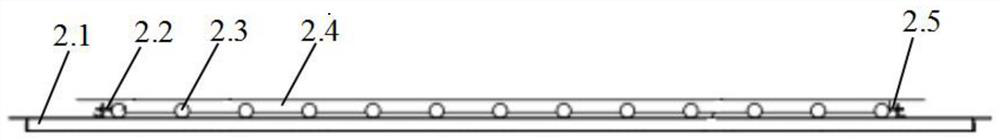

[0031] A brace for fast and precise positioning of truss nodes in truss bridges, see Figure 1-9c, and its invention point is: including truss positioning system 1, support fine-tuning system 2 and support unloading device 3. The truss positioning system is arranged above the support fine-tuning system, and the support fine-adjustment system is arranged above the support unloading device. The support unloading device adopts a sulfur sand box, and the resistance wire is evenly wound in the sulfur sand box, and a sand discharge hole is reserved. When the power is turned on, the resistance wire heats up to make the mortar evenly melt and release the sand, so as to realize the removal of the support drop frame.

[0032] The truss positioning system includes a steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com