Wooden door frame and mounting method

A door frame and wooden square technology, which is applied in the direction of window/door frame, window/door, frame fixing, etc., can solve the problems of low structural strength, poor stability, complicated process, etc., and achieve simple installation structure, high structural strength and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

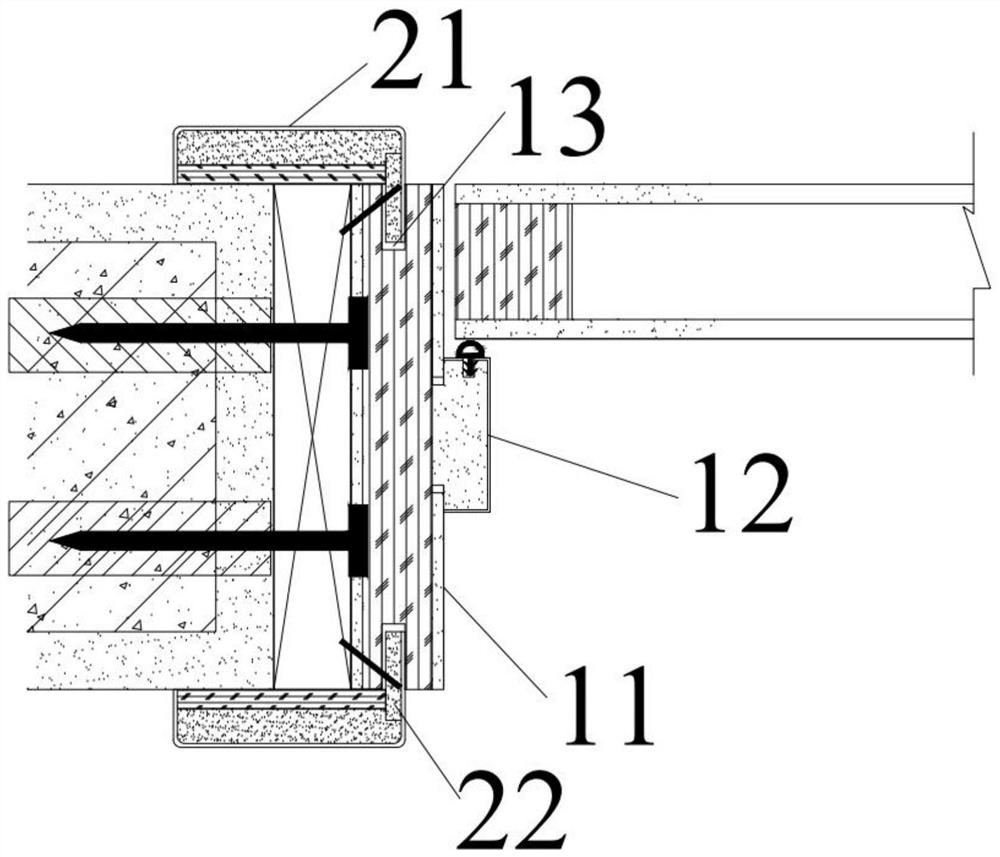

[0034] First, the door frame fixing plate 11 is produced, and the door frame fixing plate 11 is formed by two-side vertical frame and the horizontal frame, and the frame structure is formed by high precision 45 ° angle saw, and the two ends of the cross-sides and the horizontal frame are 45 ° angle. The wedge-shaped card and the screw are fixed at the splicing. Since the end cut angle forms 45 ° angle, the splicing frame is relatively vertical after the splicing is completed, ensuring the door frame 1 overall 90 ° Verticalness.

[0035] After completing the splicing of the door frame fixing plate 11, the on-side vertical frame and the connecting sewing of the horizontal frame are processed.

Embodiment 2

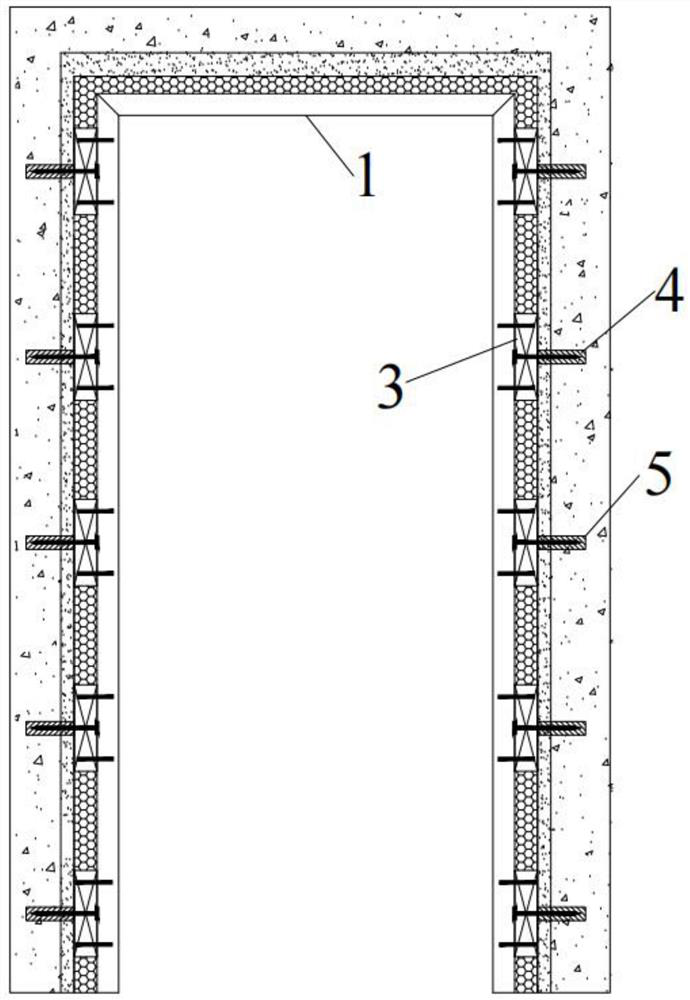

[0037] Since the diameter of the embedded square 4 is slightly larger than the fitted hole 5 opened on the side wall of the door slot, the pair of wood is knocked into the embedding hole 5, due to the specification, the square 4 is in the fitted hole 5 DND Thereby, the truck is inserted, the wood side 4 and the embedding hole 5 prevent the embedded hole 5 from slipping out of the fitted hole 5. The iron nice is knocked into the pair of embedded woods in the axis of the pinch plate 3, and the iron nail is connected to the pair of pieces 3 and the pair of wood, thereby fixing the embedded square 4 and the pinch plate 3, so that the clip The block plate 3 is fixedly mounted on the inner wall of the doorway wall.

[0038]According to the height of the door frame 1, the number of arrangements of the fitting hole 5 and the clip plate 3 is left, and the gap is left between the clamp plate 3, and the door frame fixing plate 11 is posted on the pinch plate 3, and the door frame fixing plat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap