Anti-scouring high-pressure adjusting valve capable of achieving sealing and adjusting staggering and flow adjusting method of anti-scouring high-pressure adjusting valve

A high-pressure regulating valve, staggered technology, applied in the field of regulating valves, can solve the problems of flash evaporation, large flushing and short service life of the sealing surface of the valve body, and achieve the effect of ensuring sealing and regulating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

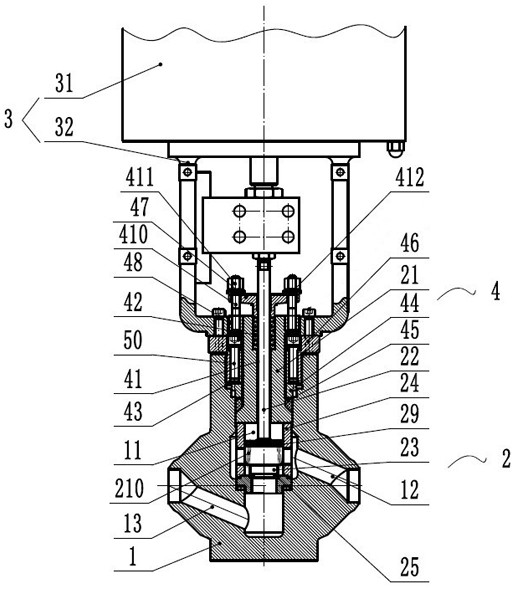

[0034] like figure 1 It shows an embodiment of a staggered anti-scouring high-pressure regulating valve that realizes sealing and regulation in the present invention, including

[0035] A valve body 1, the valve body 1 has a flow channel 11 for the flow of the medium, and the valve body 1 also has a medium inlet 12 and a medium outlet 13 that communicate with the flow channel 11;

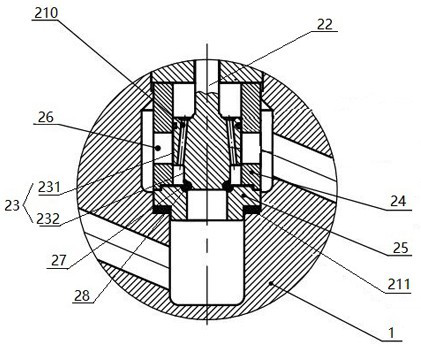

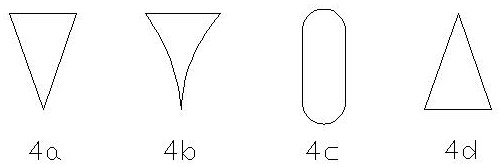

[0036] A staggered opening and closing structure 2, such as figure 2 As shown, the staggered opening and closing structure 2 includes a valve cover 21 and a valve stem 22 placed in the valve body 1, the lower end of the valve stem 22 is placed in the flow channel 11 and the lower end of the valve stem 22 is connected with a valve flap 23, as Figure 4As shown, the valve flap 23 is composed of an upper adjustment pair 231 and a lower sealing pair 232. The valve flap 23 is a T-shaped structure with a wide top and a narrow bottom. The flow channel 11 has a cage 24 distributed up and down and a valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com