Two-stage heating system for recycling waste heat of industrial wastewater based on negative pressure flash principle

A technology of industrial wastewater and two-stage heating, which is applied in heating systems, hot water central heating systems, heating methods, etc., can solve the problems of industrial wastewater waste energy waste, etc., to improve energy utilization, reduce heating costs, and improve supply efficiency. The effect of thermal mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] The present invention aims at the problems of insufficient peak-shaving capability during the heating period of thermal power plants and large waste of industrial waste water in the plant, and combines electric compression heat pumps, flash tanks, and shell-and-tube heat exchangers for heating in a heating network cycle Water can improve the flexibility of peak regulation during the heating period of the power plant while recovering the low-temperature waste heat of industrial wastewater, improve the energy utilization rate of the entire system, reduce heating costs, improve the quality of heating supply, and achieve the purpose of energy saving and emission reduction.

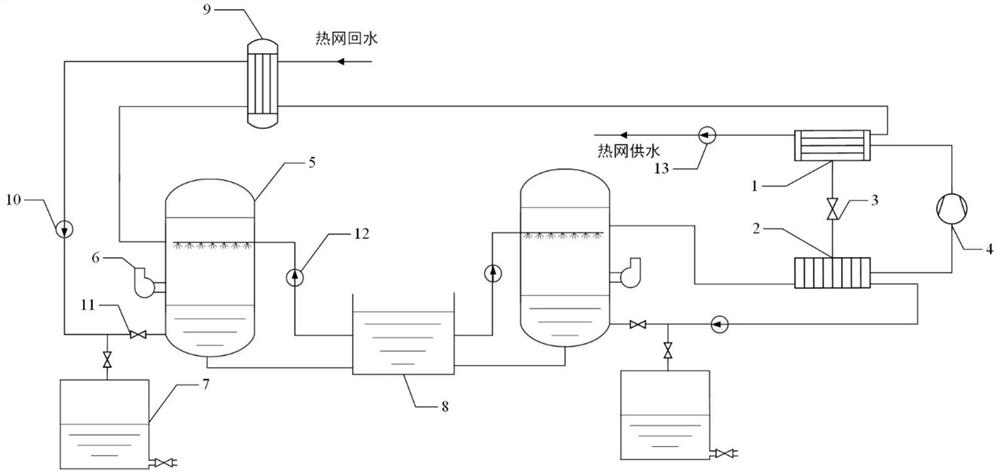

[0026] Such as figure 1 As shown, the present invention provides a two-stage heating system based on the principle of negative pressure flash to recover waste heat from industrial wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com