Heating method and heating system for combined heat and power unit

A combined heat and power unit and unit technology, applied to heating systems, hot water central heating systems, and central heating, can solve the problem that the loss of low-pressure cylinder exhaust cold source cannot be fully utilized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

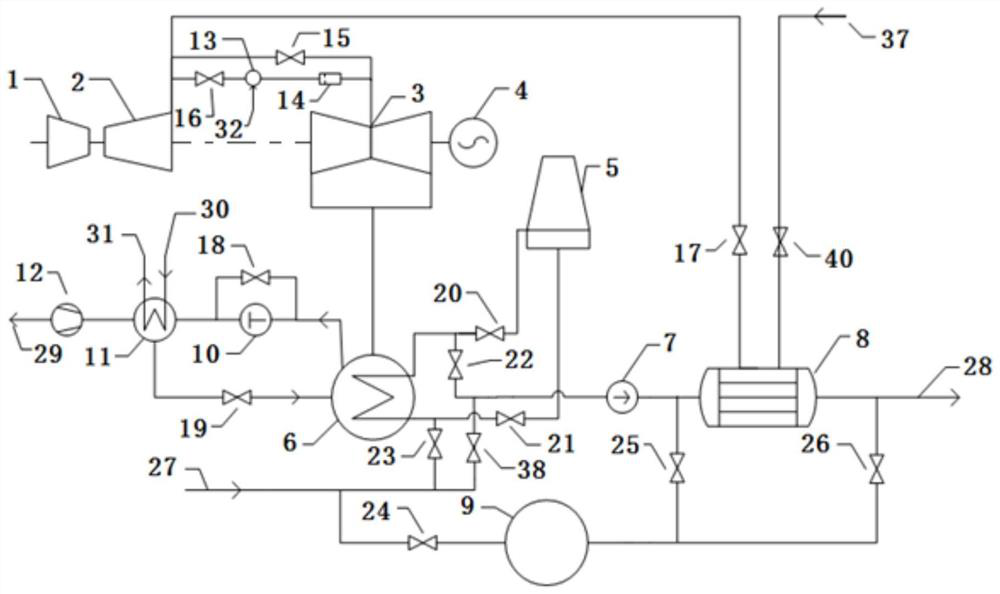

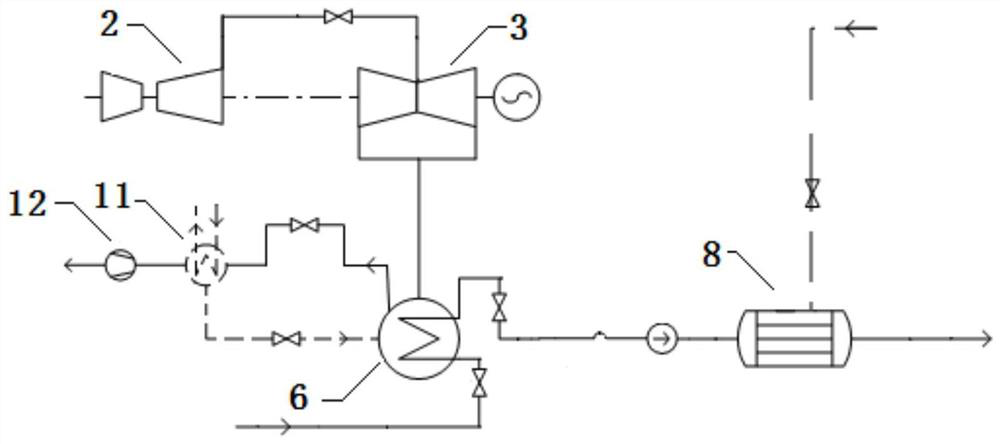

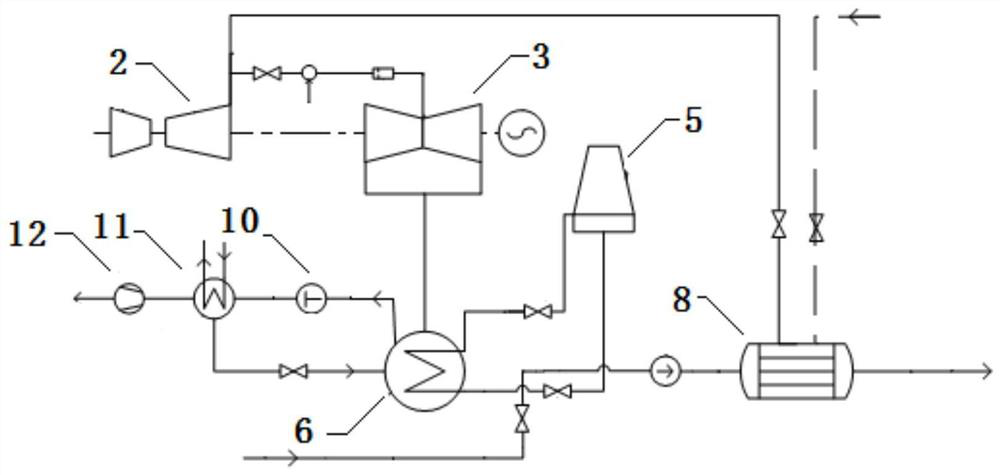

[0030] refer to figure 1 , this embodiment provides a heat supply system for cogeneration units, figure 1 The steam turbine regenerative extraction system and the condensing / feeding water system are omitted in the paper, and the heating system also omits other auxiliary equipment, and only the main equipment is systematically described. The heating system mainly includes high pressure cylinder 1, medium pressure cylinder 2, low pressure cylinder 3, generator 4, cooling tower 5, condenser 6, heat network return pump 7, heat network heater 8, heat storage device 9, auxiliary Vacuumizing device 10, steam cooler 11, vacuum pump 12 and controller. Because the cooling tower 5 is adopted, the heat supply system of this embodiment is suitable for wet cooling units and indirect air cooling units.

[0031] The exhaust port of the high-pressure cylinder 1 communicates with the steam inlet of the medium-pressure cylinder 2 .

[0032] The exhaust port of the medium-pressure cylinder 2 a...

Embodiment 2

[0100] refer to Figure 8 , this embodiment provides a heat supply system for cogeneration units, Figure 8 The steam turbine regenerative extraction system and the condensing / feeding water system are omitted in the paper, and the heating system also omits other auxiliary equipment, and only the main equipment is systematically described. The heating system mainly includes high-pressure cylinder 1, medium-pressure cylinder 2, low-pressure cylinder 3, generator 4, condenser 6, heat network return pump 7, heat network heater 8, heat storage device 9, and auxiliary vacuum device 10 , steam cooler 11, vacuum pump 12, air-cooled island 33, exhaust device 34 and controller. Because the air cooling island 33 is used, the heating system of this embodiment is suitable for direct air cooling units.

[0101]The exhaust port of the high-pressure cylinder 1 communicates with the steam inlet of the medium-pressure cylinder 2 .

[0102] The exhaust port of the medium-pressure cylinder 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com