A steam injector and its structural optimization method

An optimization method and injector technology, applied in jet pumps, design optimization/simulation, machines/engines, etc., can solve the problems of low steam turbine exhaust pressure, heat loss, environmental pollution, etc., achieve high thermal efficiency and reduce plant power consumption Reasonable design of efficiency and structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

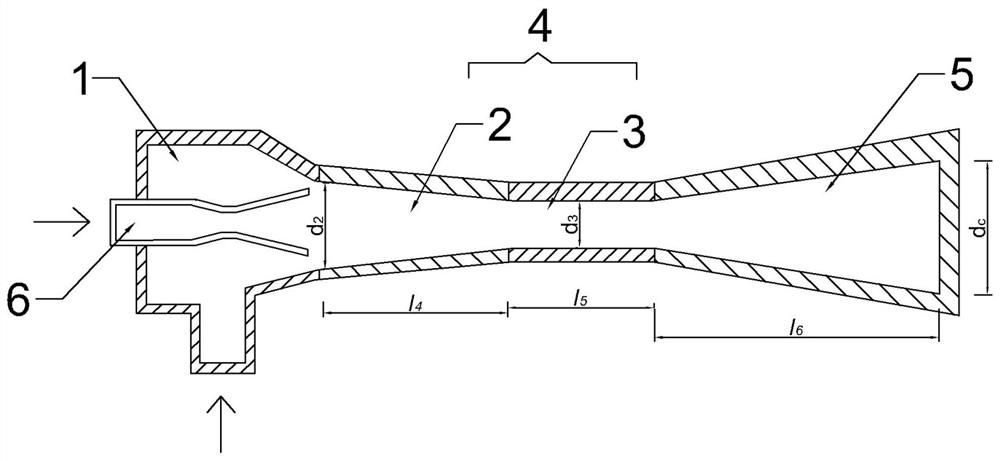

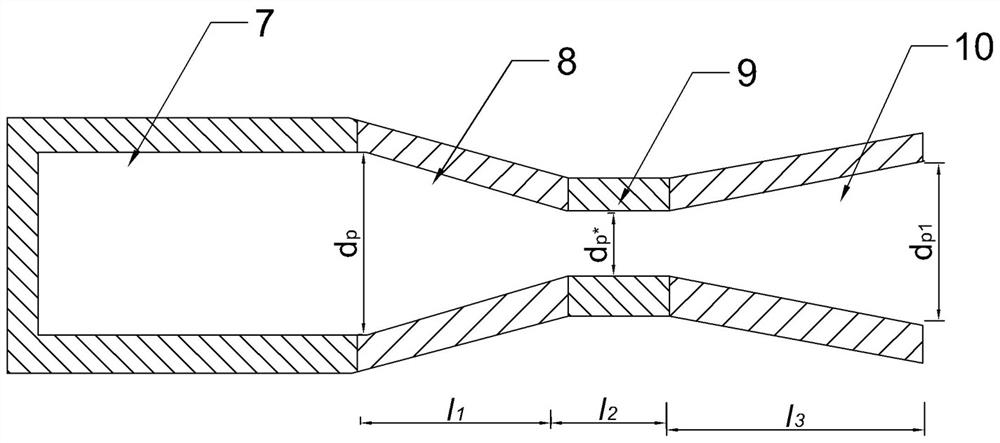

[0055] like figure 1 and 2 As shown, a steam ejector includes a receiving chamber 1 communicated with each other, a mixing chamber 4, a diffuser chamber 5, and a nozzle 6 arranged at the entrance of the receiving chamber 1. Air inlet; the mixing chamber 4 includes a converging section 2 and a transition section 3, and the nozzle 6 includes an inlet section 7, a converging section 8, a throat section 9 and an expansion section 10; the transition section 3 and the throat section 9 is a hollow cylinder.

[0056] The structure optimization method of the steam injector, for the nozzle throat section diameter x 1 , the diameter of the end of the expansion section x 2 , the diameter of the transition section x 3 , the shrinkage section length of the mixing chamber x 4 and transition length x 5 Five structural parameters were optimized. Include the following steps:

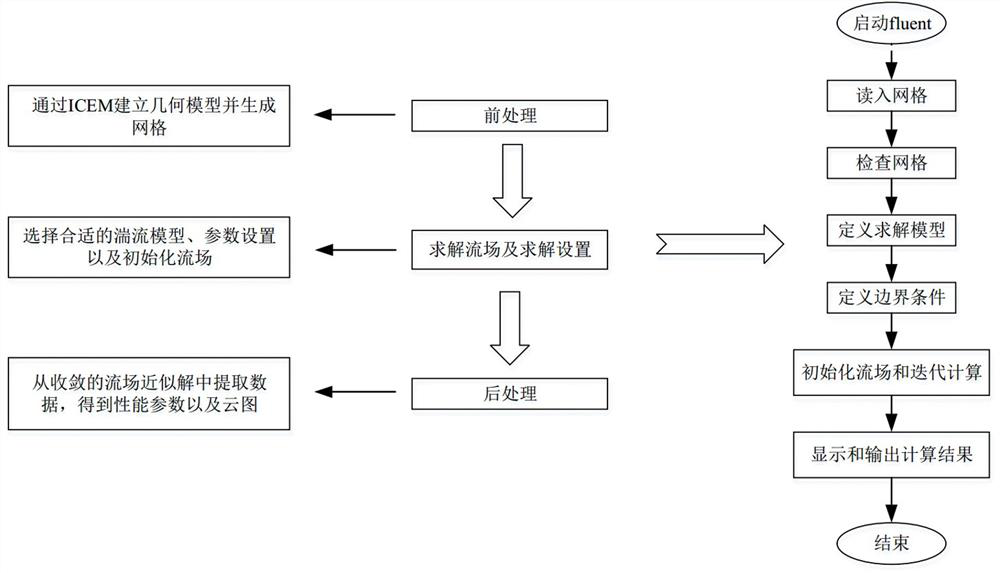

[0057] (1) CFD numerical simulation:

[0058] like image 3 As shown, the CFD numerical simulation process is...

Embodiment 2

[0110] A steam ejector, comprising a receiving chamber 1, a mixing chamber 4, a diffuser chamber 5 communicated with each other, and a nozzle 6 arranged at the entrance of the receiving chamber 1, and an air inlet is arranged below the receiving chamber 1 The mixing chamber 4 includes a constriction section 2 and a transition section 3, and the nozzle 6 includes an inlet section 7, a tapering section 8, a throat section 9 and an expansion section 10; the transition section 3 and the throat section 9 are hollow Cylindrical.

[0111] The diameter of the inlet section 7 of the nozzle 6 is d p 130mm, its throat section 9 diameter d p* is 31.34mm, and the end diameter of the expansion section 10 is d p1 is 80.52mm; the diameter of the beginning end of the constriction section 2 of the mixing chamber 4 is d 2 is 220mm, the diameter d of the transition section 3 3 It is 179.14mm.

[0112] The tapered section 8 length l of the nozzle 6 1 is 101mm, and its throat section 9 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com