Internal Heating Fluidized Bed Drying System Applicable to Lignite Air-cooled Generating Units

A technology of fluidized bed drying and fluidized bed dryer, which is applied in the direction of heating to dry solid materials, drying solid materials, machines/engines, etc., which can solve the problems of environmental heat pollution, cold source loss, etc., and achieve equipment investment reduction, Low recycling cost, beneficial to the effect of stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

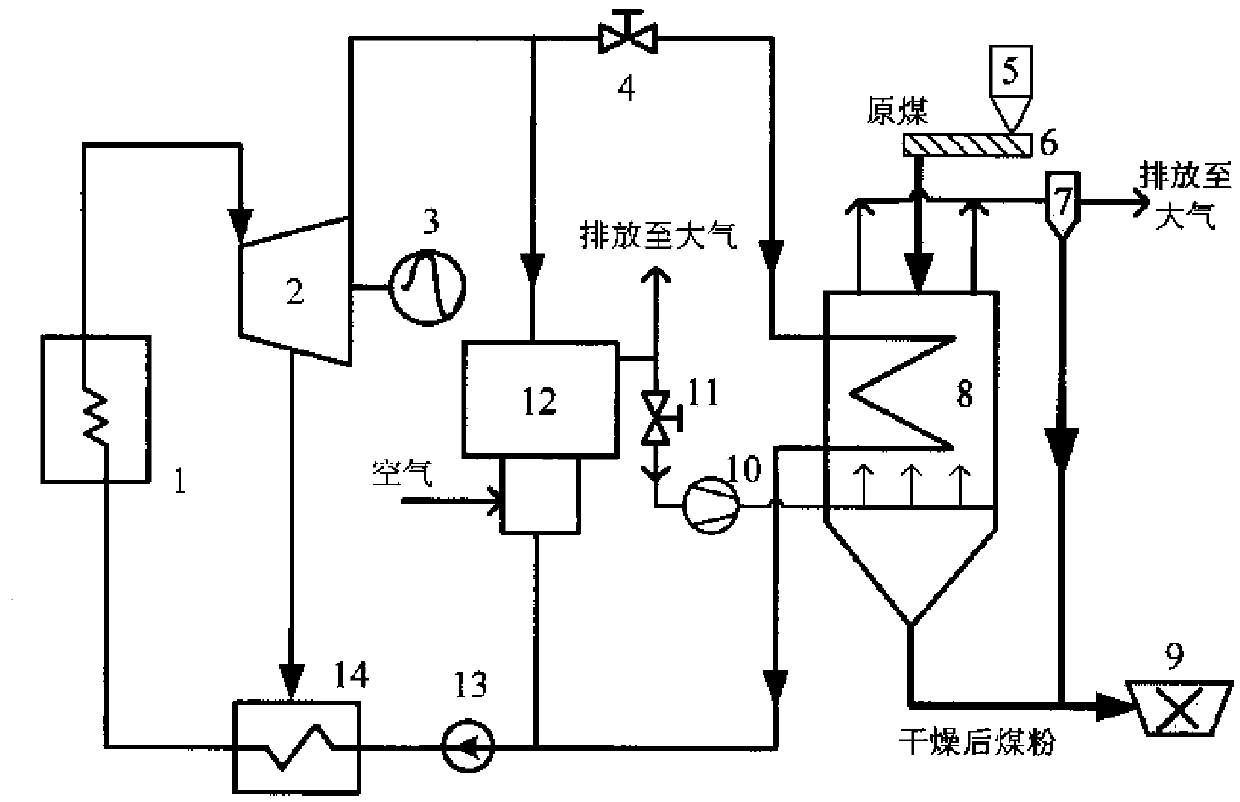

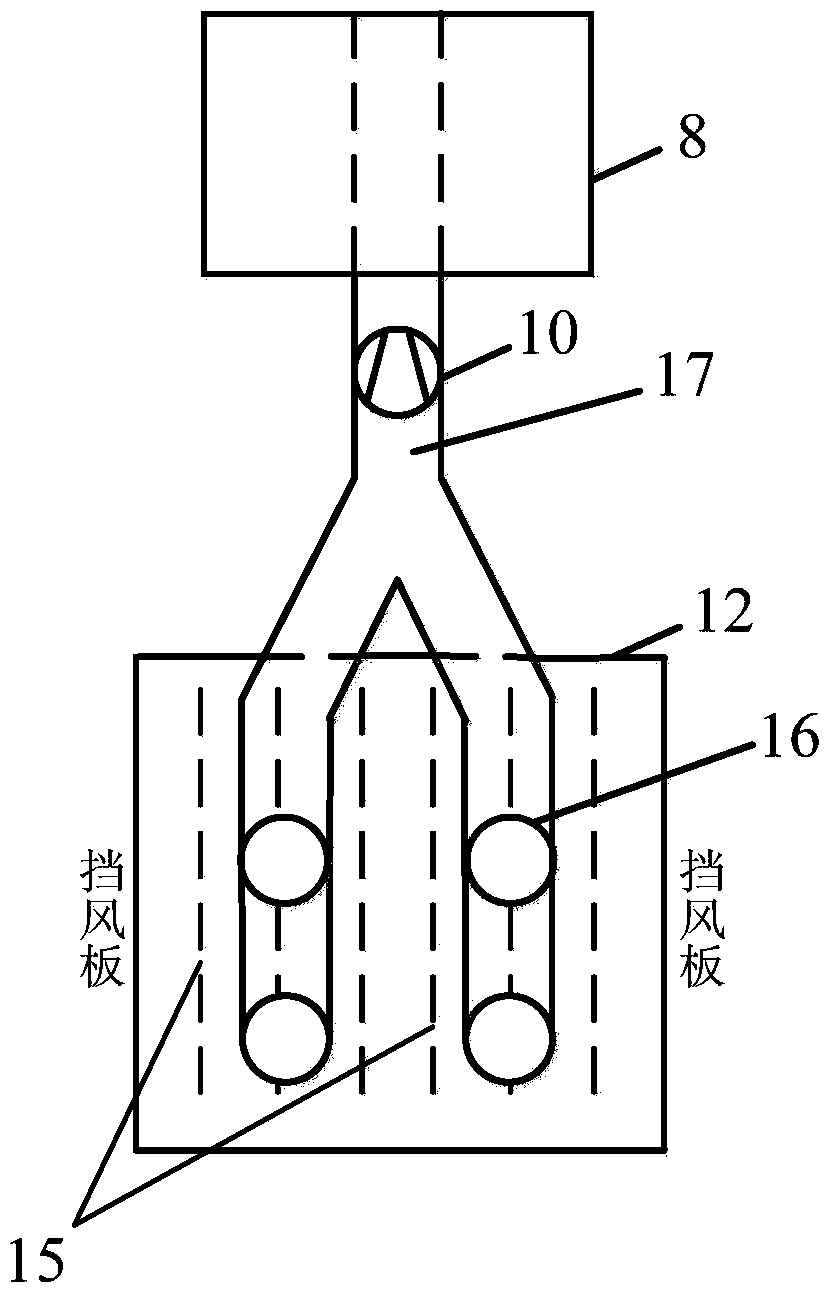

[0022] The present invention provides an internal heating fluidized bed drying system suitable for lignite air-cooled power generating units. The working principle of the system will be further described below in conjunction with the accompanying drawings and specific implementation methods.

[0023] figure 1 Shown is a schematic diagram of an internally heated fluidized bed lignite drying system suitable for air-cooled power generating units.

[0024] This system mainly adds an internal heating fluidized bed dryer 8 with a built-in heat exchanger between the coal bin 5, the weighing belt 6 and the coal mill 9 in the lignite air-cooled power generation unit, and the inlet of the built-in heat exchanger The exhaust pipe of the low-pressure cylinder connected to the steam turbine 2 of the power station, and the outlet is connected to the condensed water pipe after the air-cooling island 12 of the steam-water system of the power station. heat and latent heat of vaporization to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com