Real-time pressurizing and heating testing device and testing method for fuel cell

A pressure heating, fuel cell technology, applied in the direction of using stable tension/pressure to test the strength of materials, measuring devices, analyzing materials, etc., can solve the problems of difficult stress distribution analysis, small pressure, inability to apply horizontal pressure, etc. Accurate pressure test results, easy disassembly and installation, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

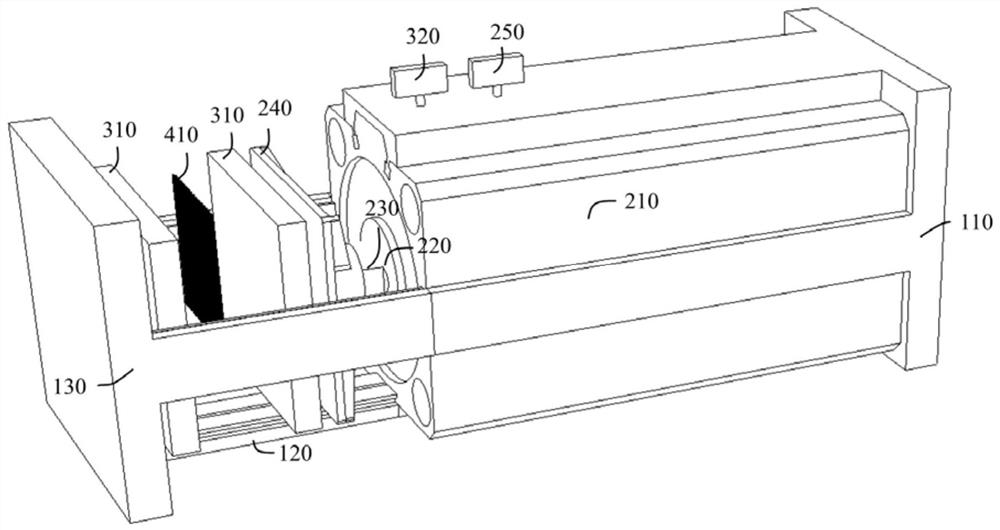

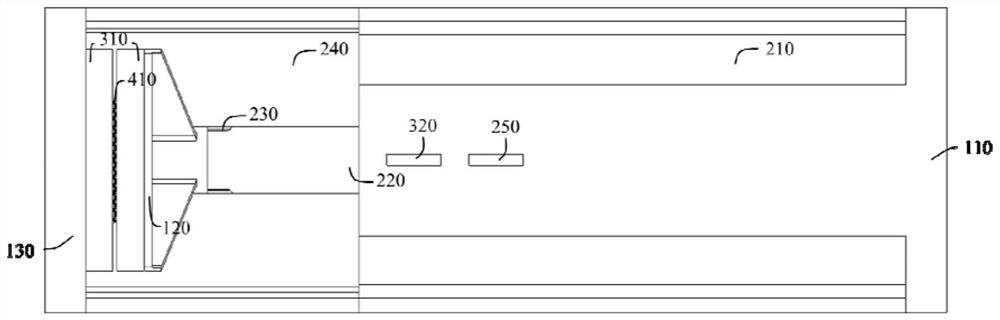

[0040] like Figure 1-10 As shown, this embodiment provides a real-time pressurized heating test device for fuel cells, the device includes a support bracket, a pressurization assembly and a heating assembly, the pressurization assembly is installed at the tail of the support bracket, and the heating assembly is installed at the head of the support bracket. Both the pressurization component and the heating component are installed in a detachable manner. The heating component includes two vertically placed heating end plates 310, and the two heating end plates 310 are used to clamp the test piece 410. The pressure of the pressure component The direction is parallel to the normal direction of the fuel cell.

[0041]Wherein, the support bracket includes a rear fixed end plate 110, a support rod 120 and a front fixed end plate 130, the rear fixed end plate 110 and the front fixed end plate 130 are arranged oppositely and are supported and fixed by a plurality of support rods 120 t...

Embodiment approach

[0044] It should be noted that, in this device, the heating component may not have any mechanical connection with other components. At this time, the two heating end plates 310 are directly standing in the supporting frame, and the test piece 410 is also directly between the two heating end plates 310. A dump occurs. Under another kind of embodiment, the heating push plate close to the pressurized push plate 240 can also be mechanically connected with the pressurized push plate 240 through a connecting piece (such as a countersunk nut), and another heating push plate can also be connected through a connecting piece (such as a countersunk nut). Countersunk nut) is directly mechanically connected to the front fixed end plate 130, so that when testing, the test piece 410 is placed upright on the heating push plate at the front. With or without mechanical connection between the above-mentioned heating assembly and other components, the heating assembly can be configured by itself...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com