A skeleton coil winding and hanging device

A skeleton coil, winding technology, applied in coil manufacturing, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problem of inconvenient hanging, easy to hit the winding mold or rotating shaft 3, reducing winding efficiency, etc. problems, to achieve the effect of improving the hanging speed and production efficiency, reducing the risk of hand being hit, and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

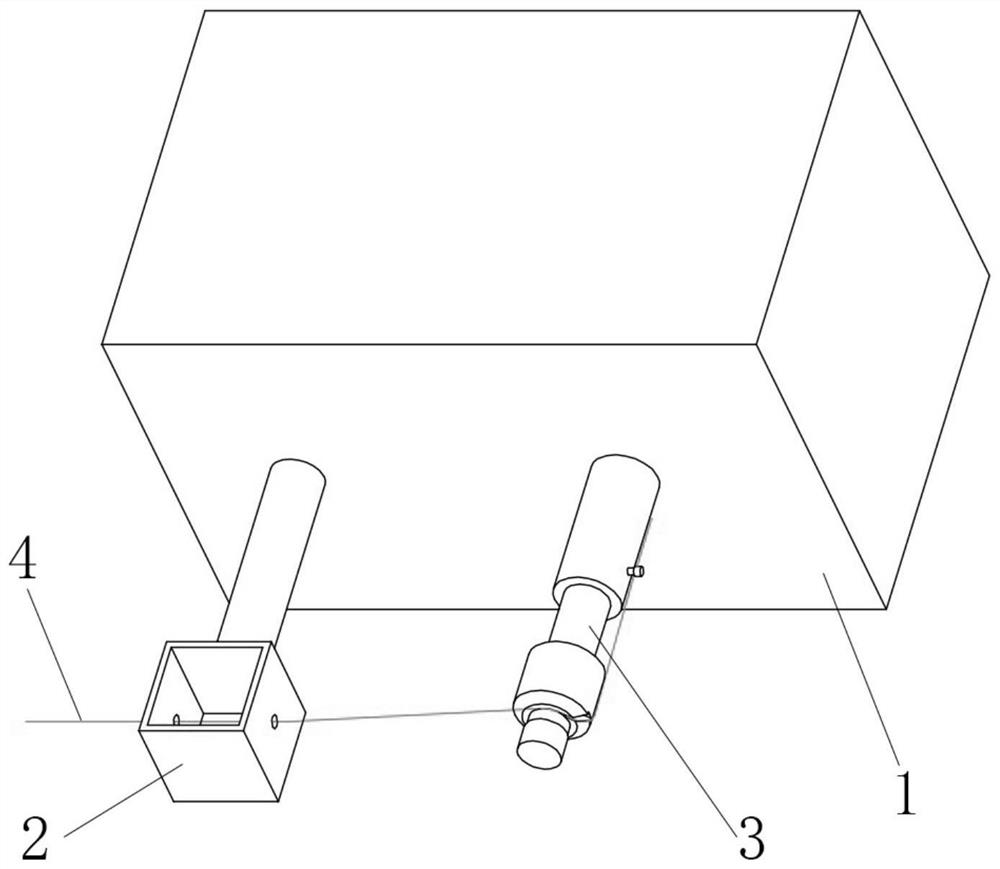

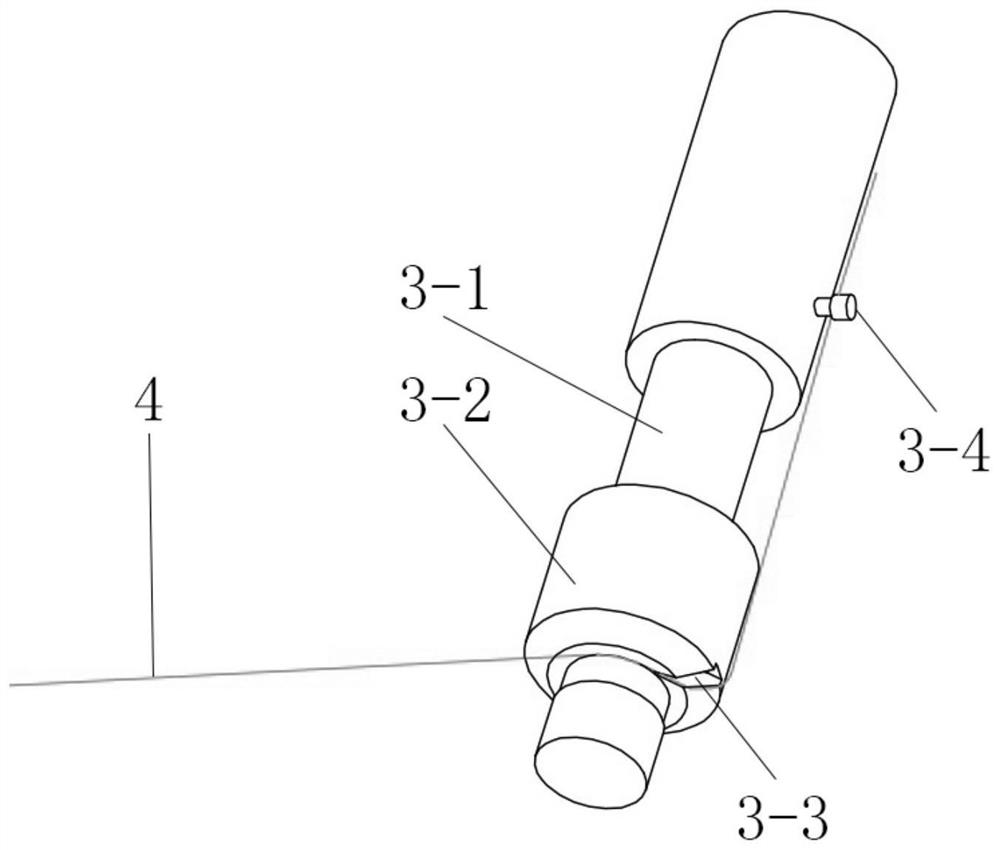

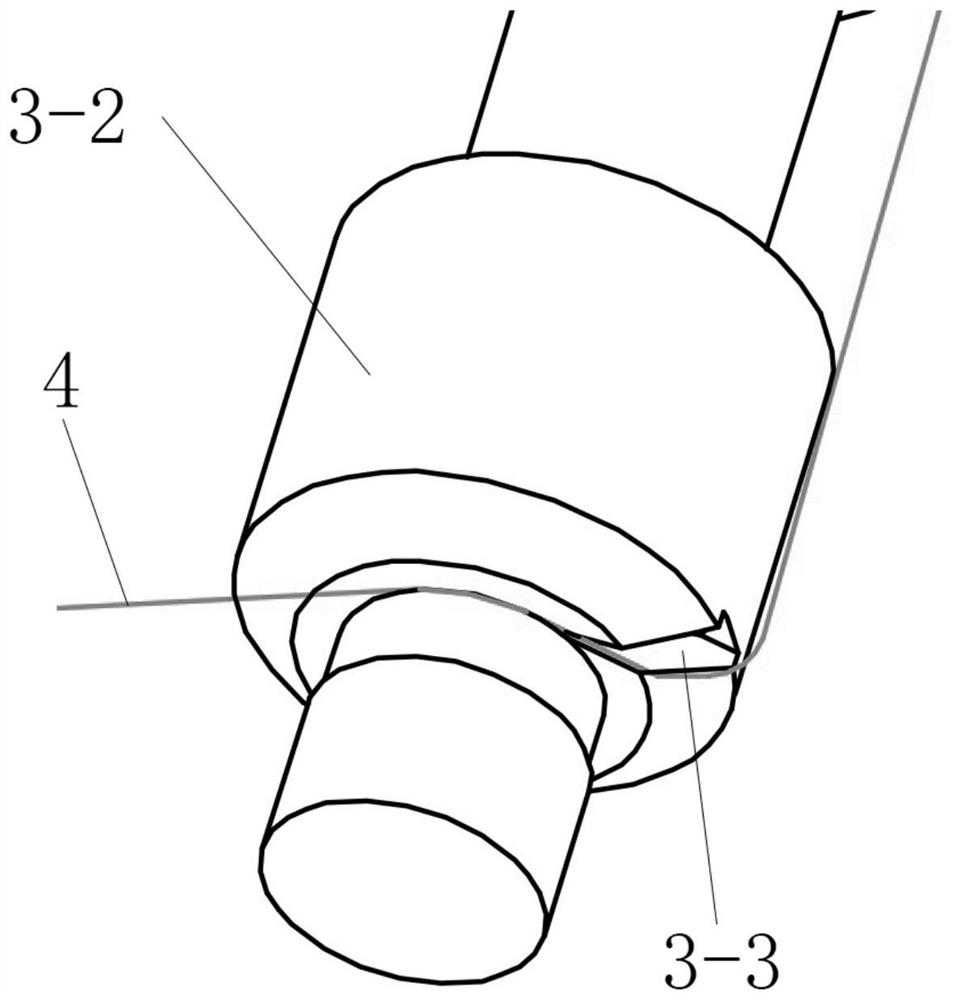

[0033] like Figure 4 , Figure 5 , Image 6 , Figure 7 Shown is one of the embodiments of the present invention. In this embodiment, a bobbin coil winding and hanging device is disclosed, including a main body 1, a driving device is arranged inside the main body 1, and a solvent box 2 and a solvent box 2 and Rotating shaft 3, the solvent box 2 is usually provided with alcohol cotton, the rotating shaft 3 is driven to rotate by the driving device, the enameled wire 4 is extended to the rotating shaft 3 through the solvent box 2, and the rotating shaft 3 is provided with a shaft sleeve 3-2, the shaft sleeve 3-2 is a part of the winding die, the sleeve 3-2 is provided with a wire slot 3-3, the rotating shaft 3 is also provided with a wire hanging disc 5, and the outer circumferential surface of the wire hanging disc 5 is provided with a positioning piece 5-3. The enameled wire 4 passes through the wire slot 3-3 and is positioned below the positioning piece 5-3.

[0034] By ...

Embodiment 2

[0051] like Figure 8 Shown is Embodiment 2 of the present invention. Different from Embodiment 1, the positioning surface 5-5 intersects the axis of the thread-hanging disk 5, and the intersection belongs to the intersection of a straight line and a plane in three-dimensional geometry.

[0052] When the positioning piece 5-3 is fixed with this design, the positioning piece 5-3 faces the staff, and it is more convenient to hang the enameled wire 4 under the positioning piece 5-3.

[0053] from Figure 8 It can also be seen that three positioning surfaces 5-5 are provided on the outer circumferential surface of the thread hanging disc 5, and three positioning pieces 5-3 can be fixed. If there is a problem with one of the positioning pieces 5-3, the other positioning pieces 5-3 can be used, which prolongs the service time of the wire hanging disc 5, and avoids the need to replace the positioning pieces 5-3 immediately, which will delay the work process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com