Dust collector applied to power plant

A technology for dust collectors and power plants, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of gas storage tank waste, reduce work efficiency, affect the operation of dust collectors, etc., to maintain normal operation, The effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

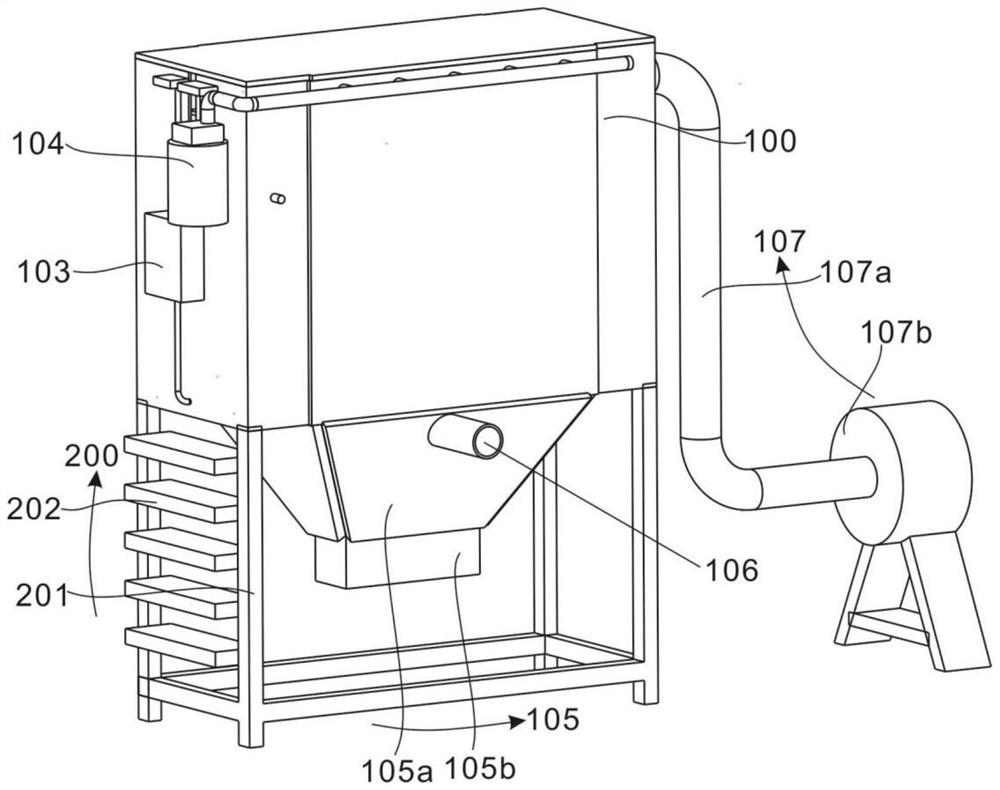

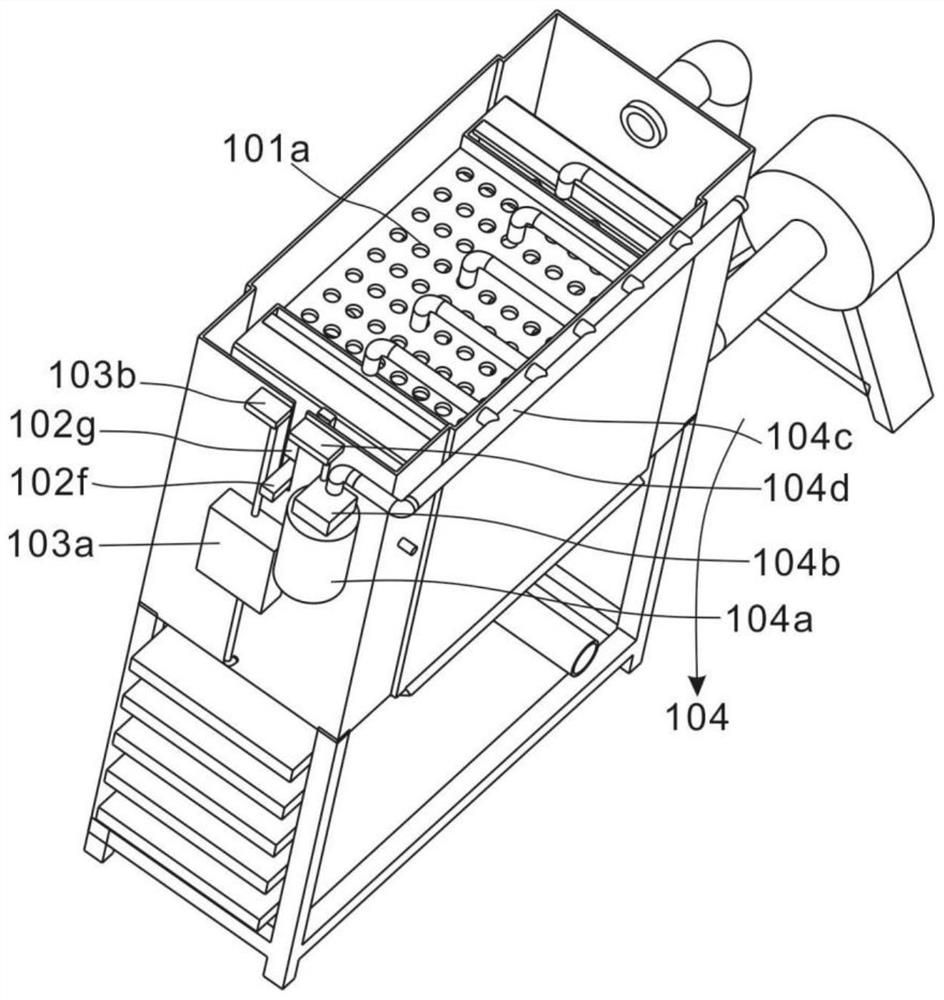

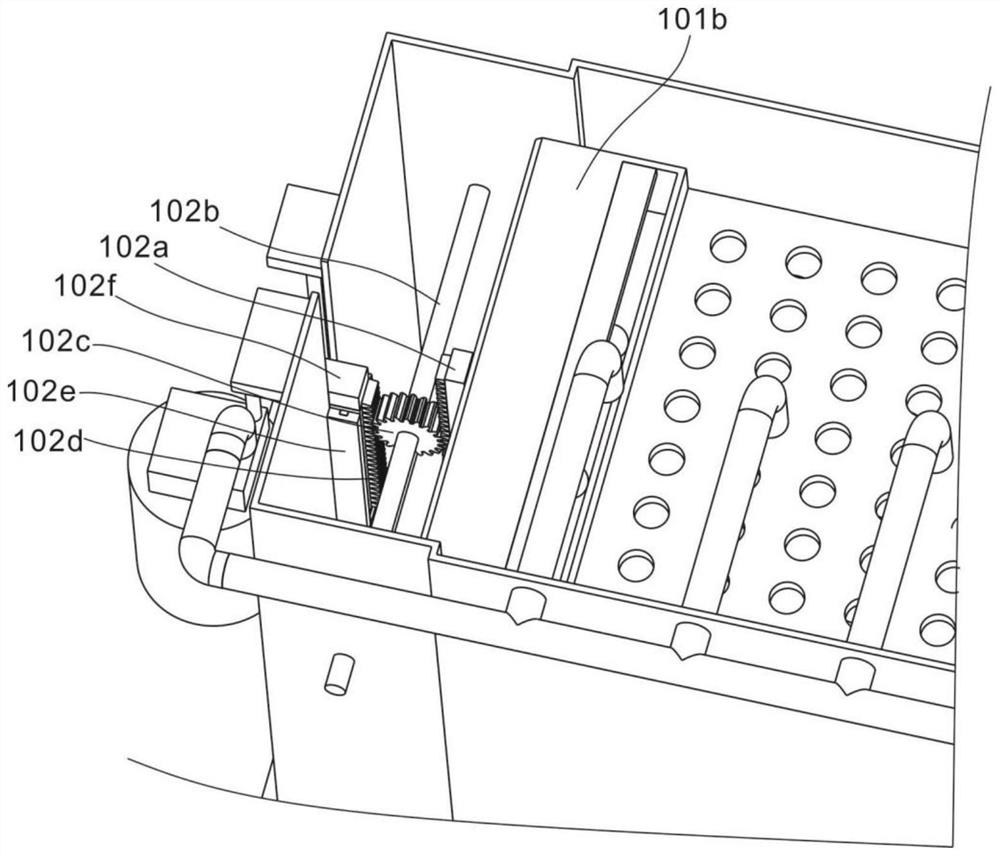

[0028] refer to Figure 1~6 , which is the first embodiment of the present invention. This embodiment provides a dust collector applied to a power plant. By technically improving the existing dust collector, the whole device does not need to be attended by manpower during operation, and the dust removal and cleaning are performed automatically. , reducing labor costs and saving energy.

[0029] Specifically, the closed casing 100 includes a vibration lift filter assembly 101 placed in the closed casing 100, a trigger assembly 102 connected to the side of the vibration lift filter assembly 101, a power supply assembly connected to the trigger assembly 102 103 and the recoil air flow assembly 104, the hopper assembly 105 connected to the vibrating lifting filter assembly 101, and the air inlet pipe 106 arranged on the side of the hopper assembly 105;

[0030] The maintenance support assembly 200 includes a support and protection frame 201 connected to the main body 100 of the d...

Embodiment 2

[0041] refer to figure 1 , is the second embodiment of the present invention, which is different from the first embodiment in that: it also includes a heating plate 105a and a switching valve 105b. In the last embodiment, the dust remover applied to the power plant includes the technical improvement of the existing dust remover, so that the whole device does not need to be attended by manpower during operation, and the dust removal and cleaning are performed automatically, which reduces labor costs and saves energy.

[0042] Specifically, the closed casing 100 includes a vibration lift filter assembly 101 placed in the closed casing 100, a trigger assembly 102 connected to the side of the vibration lift filter assembly 101, a power supply assembly connected to the trigger assembly 102 103 and the recoil air flow assembly 104, the hopper assembly 105 connected to the vibrating lifting filter assembly 101, and the air inlet pipe 106 arranged on the side of the hopper assembly 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com