Desulfurization treatment device and treatment process thereof

A technology of processing device and supporting device, applied in mixers with rotary stirring device, petroleum industry, transportation and packaging, etc., can solve the problem of insufficient contact between sulfur-containing gas and desulfurizer, reduce desulfurization efficiency, and reduce the utilization rate of desulfurizer and other problems, to achieve the effect of improving utilization rate, improving desulfurization efficiency and saving cost

Pending Publication Date: 2021-08-13

滁州滁能热电有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] When the existing desulfurization equipment uses desulfurization agent for desulfurization, the contact between the sulf

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

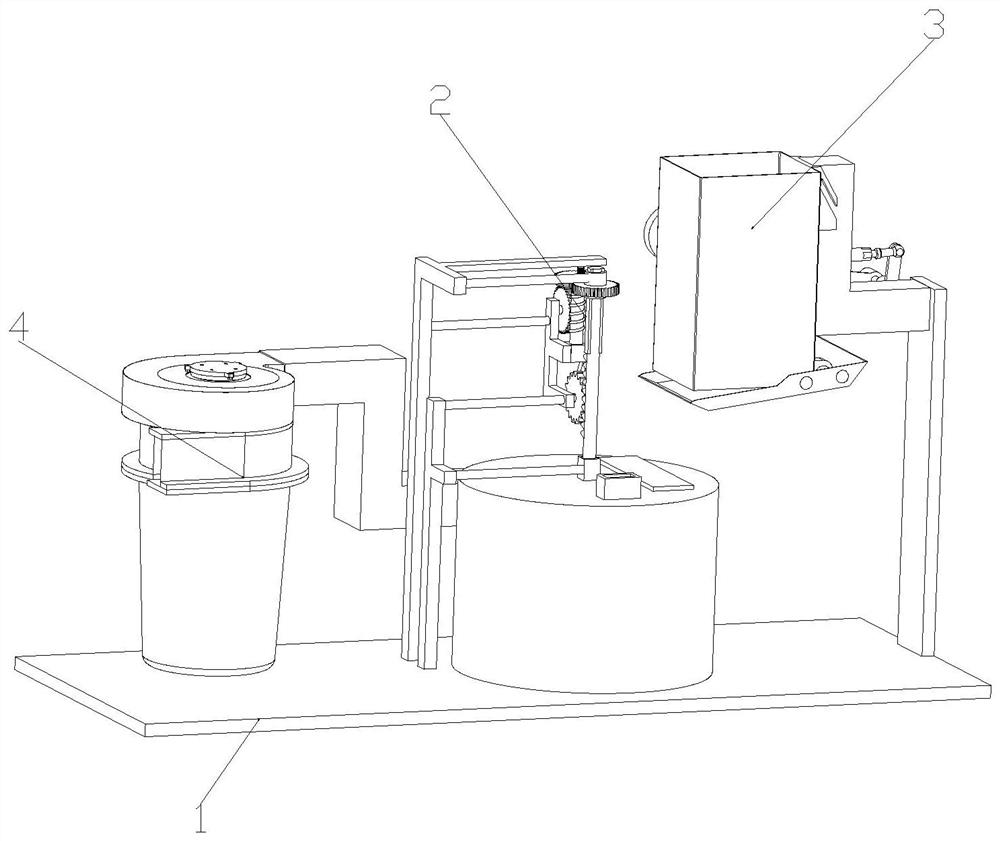

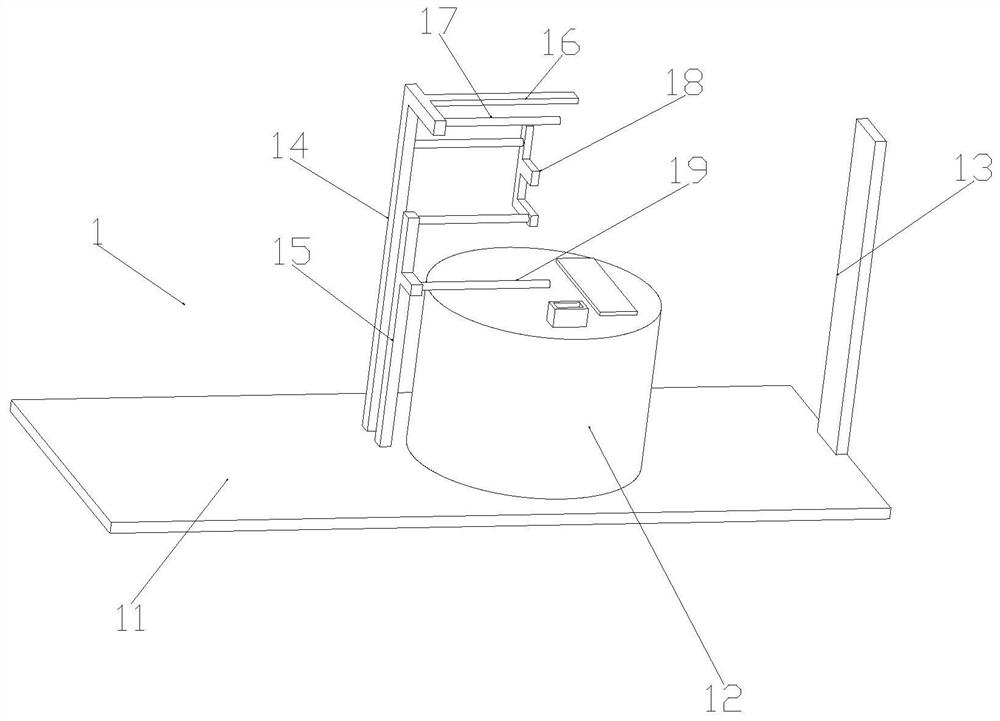

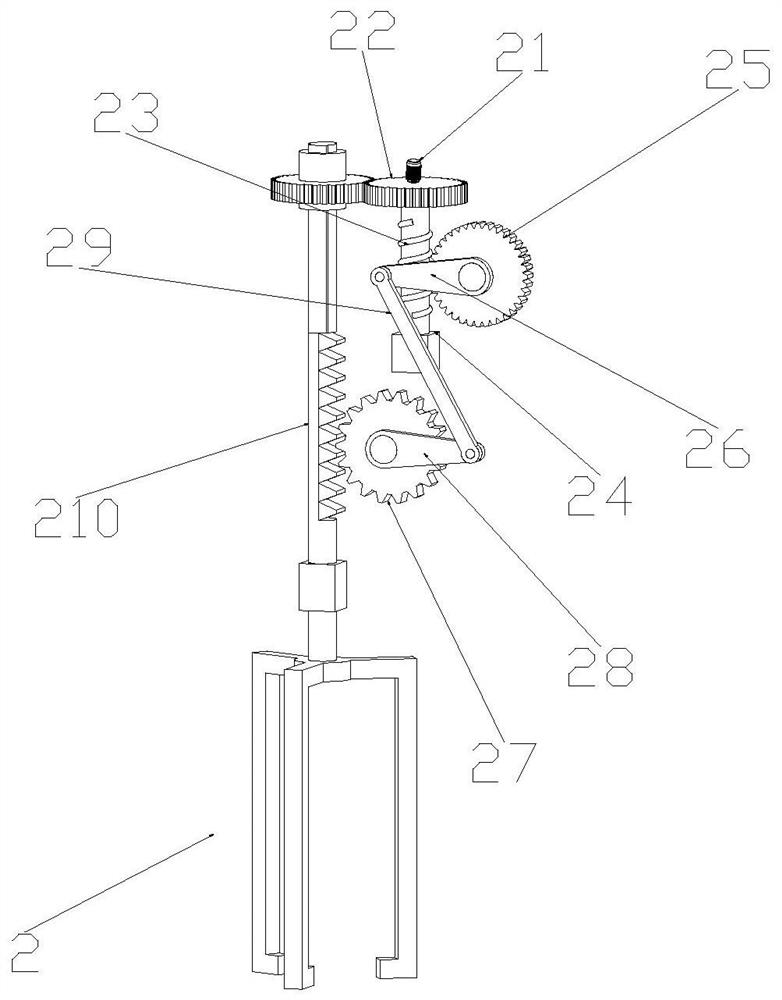

The invention relates to the technical field of desulfurization equipment, and discloses a desulfurization treatment device and a treatment process thereof. The desulfurization treatment device comprises a supporting device, a stirring device is arranged above the supporting device, an automatic material falling device is arranged on one side of the stirring device, and a dust removal device is arranged on the other side of the stirring device; the stirring device drives stirring blades to rotate through the operation of a stirring motor, and also drives the stirring blades to move along the vertical direction, so that sulfur-containing gas and a desulfurizing agent solution are more in full contact, and the desulfurizing efficiency is improved; the automatic material falling device drives a blocking cover to open and close through the operation of an electric cylinder, and can automatically add desulfurizer crystals into a desulfurization barrel, so that the working efficiency is improved; and a modifier is added into a desulfurizing agent used in the desulfurization treatment process, so that the utilization rate of the desulfurizing agent is increased, and the cost is saved.

Description

technical field [0001] The invention relates to the technical field of desulfurization equipment, in particular to a desulfurization treatment device and a treatment process thereof. Background technique [0002] Desulfurization generally refers to the process of removing sulfur from fuel before combustion and before flue gas emission. It is one of the important technical measures to prevent and control air pollution. [0003] When the existing desulfurization equipment uses the desulfurizer for desulfurization, the contact between the sulfur-containing gas and the desulfurizer is insufficient, which reduces the desulfurization efficiency. utilization rate. Contents of the invention [0004] In order to solve the above-mentioned deficiencies mentioned in the background technology, the purpose of the present invention is to provide a desulfurization treatment device, including a support device, a stirring device is provided above the support device, and an automatic blank...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01F15/00B01F7/16B01F7/18B01F15/02B01D53/48C10L3/10

CPCB01D53/48C10L3/103B01F27/85B01F27/90B01F35/4111B01F35/184B01F35/71

Inventor 牟永春

Owner 滁州滁能热电有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com