A granulator for traditional Chinese medicinal materials

A technology of pelletizer and medicinal materials, which is applied in grain processing and other directions, can solve the problems of Chinese medicinal materials staying, feeding stuck, and Chinese medicinal materials advancing, and achieves the effects of improving practicability, preventing stuck and improving friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

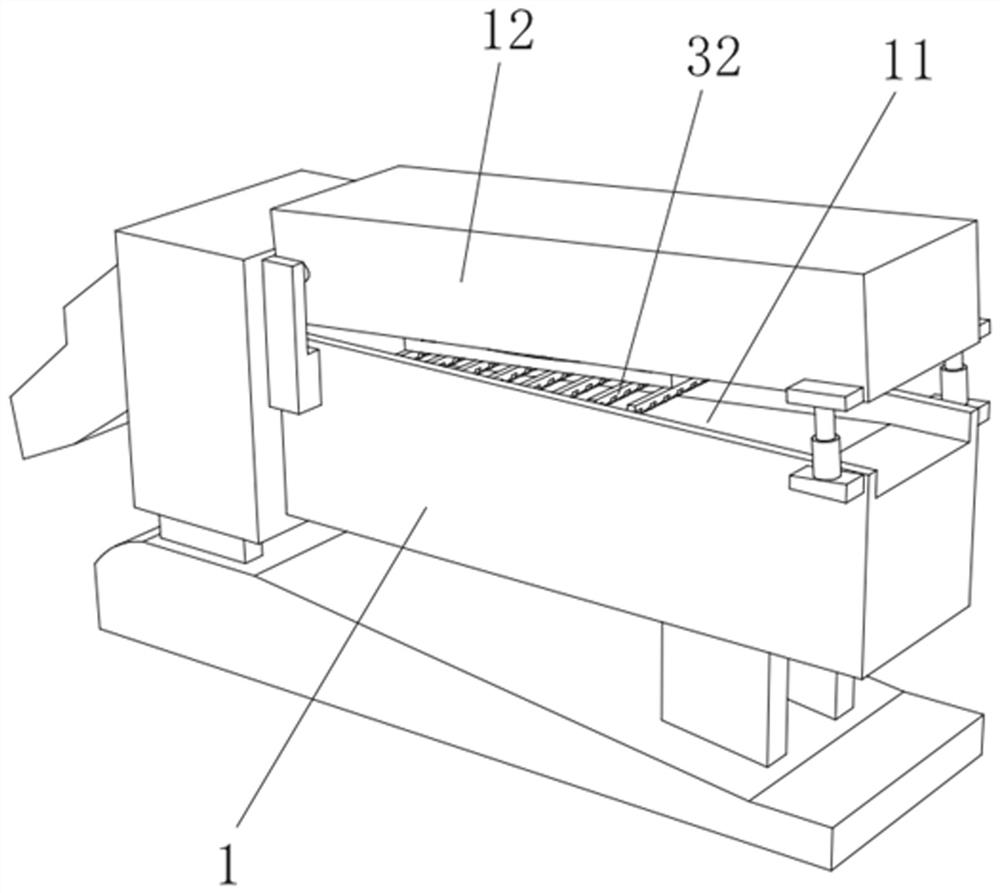

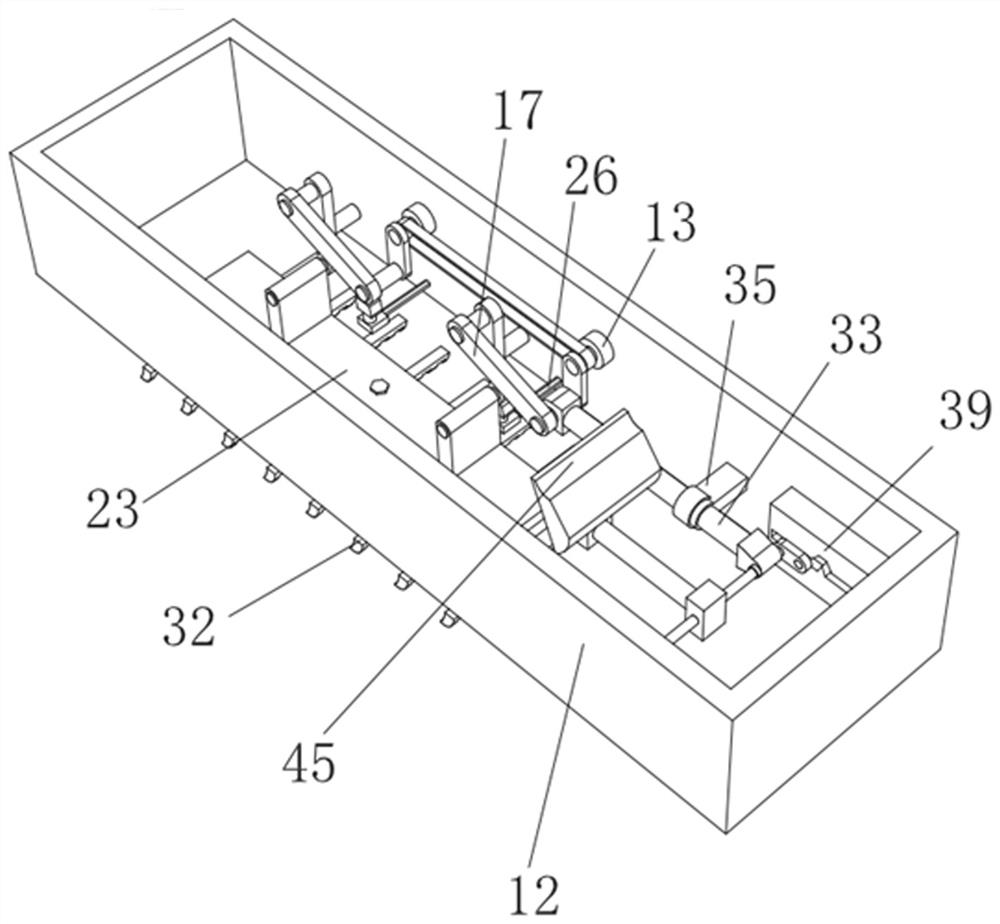

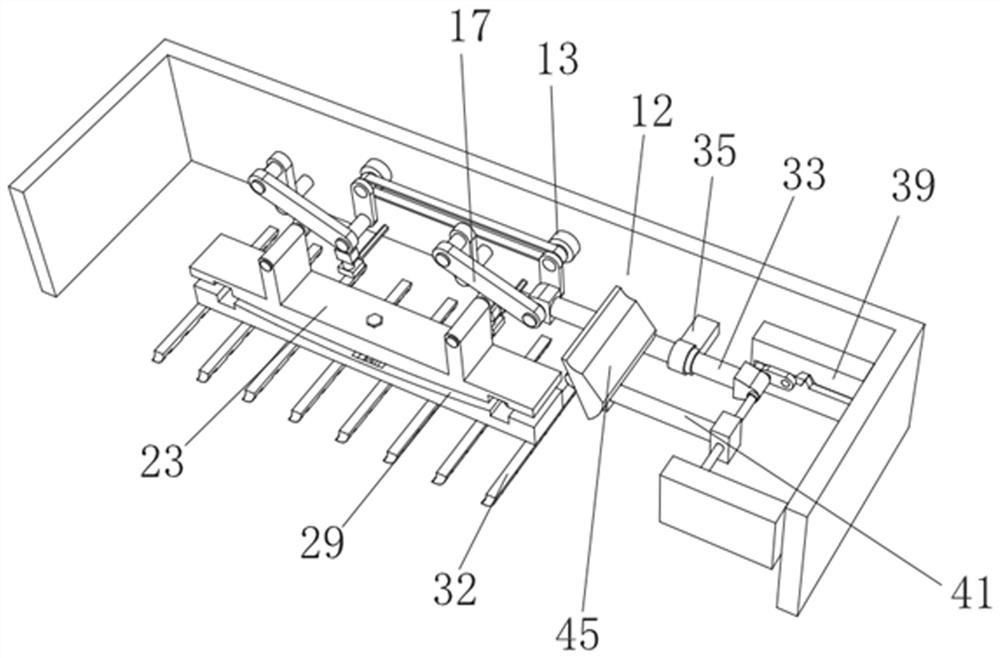

[0037] Example 1: Combining figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a granulator for traditional Chinese medicinal materials, comprising a granulator body 1, a feed trough 11 is arranged on the granulator body 1, an upper top box 12 is fixedly installed on the granulator body 1, and a top box 12 is fixedly installed on the granulator body 1 It is provided with a suspension mechanism, a toggle mechanism and an auxiliary dial mechanism, wherein the suspension mechanism includes a motor body 13, the motor body 13 is fixedly installed on the inner side wall of the top box 12, and the outer surface of the shaft rod of the motor body 13 is sleeved with a rectangular connecting rod. Rod one 14, the end of rectangular connecting rod one 14 is fixedly equipped with rotating rod two 15, the outer surface of rotating rod two 15 is movably socketed with main connecting rod 17, and the inner surface of main connecting rod 17 is movably socketed with rotating rod thre...

Embodiment 2

[0039] Embodiment 2 is on the basis of embodiment 1: combine figure 1 , figure 2 , image 3 and Figure 6 , the granulator body 1 is provided with a toggle mechanism, the toggle mechanism includes a main pull plate 23, the main pull plate 23 is connected with two suspension mechanisms through two rotating rods 5 22, and the two rotating rods 5 22 are movably socketed In the main pull plate 23, a bottom plate 29 is installed at the end of the main pull plate 23, a spring three 31 is fixedly installed between the main pull plate 23 and the bottom plate 29, and a T-shaped bar 27 is fixedly installed on the inner surface of the main pull plate 23. The end of word bar 27 is fixedly installed with two springs 28, offers rectangular groove 3 on the base plate 29, and T word bar 27 is fixedly installed in the rectangular groove 3 of base plate 29 by two springs 28, and the end of base plate 29 A curved plate 32 is fixedly installed.

[0040] When in use, the main pull plate 23 dr...

Embodiment 3

[0042] Embodiment 3 is on the basis of embodiment 1: combine figure 1 , figure 2 , image 3 and Figure 7 , the granulator body 1 is provided with an auxiliary dial mechanism, the auxiliary dial mechanism includes a rod sleeve 16, and the rod sleeve 16 is fixedly sleeved on the outer surface of the rotating rod 2 15, and the end of the rod sleeve 16 is fixedly equipped with an auxiliary rotating shaft. Rod 49, the end of auxiliary rotating rod 49 is rotatably connected with main sliding rod 33, and between auxiliary rotating rod 49 and main sliding rod 33 is movably connected with rotating rod one, and the end of main sliding rod 33 is fixedly installed with rod cover two 34 , a support sleeve 35 is fixedly installed between the main sliding rod 33 and the upper top box 12, and the inner surface of the rod sleeve 2 34 is movably equipped with a main rotating rod 36, and the end of the main rotating rod 36 is fixedly installed with two rotating plates 37, The end of rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com