Mold forming device for High-power semiconductor device package

A device packaging and mold forming technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, household components, etc., can solve problems such as product damage, difficulty in demoulding molded products, affecting product molding effect and molding quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

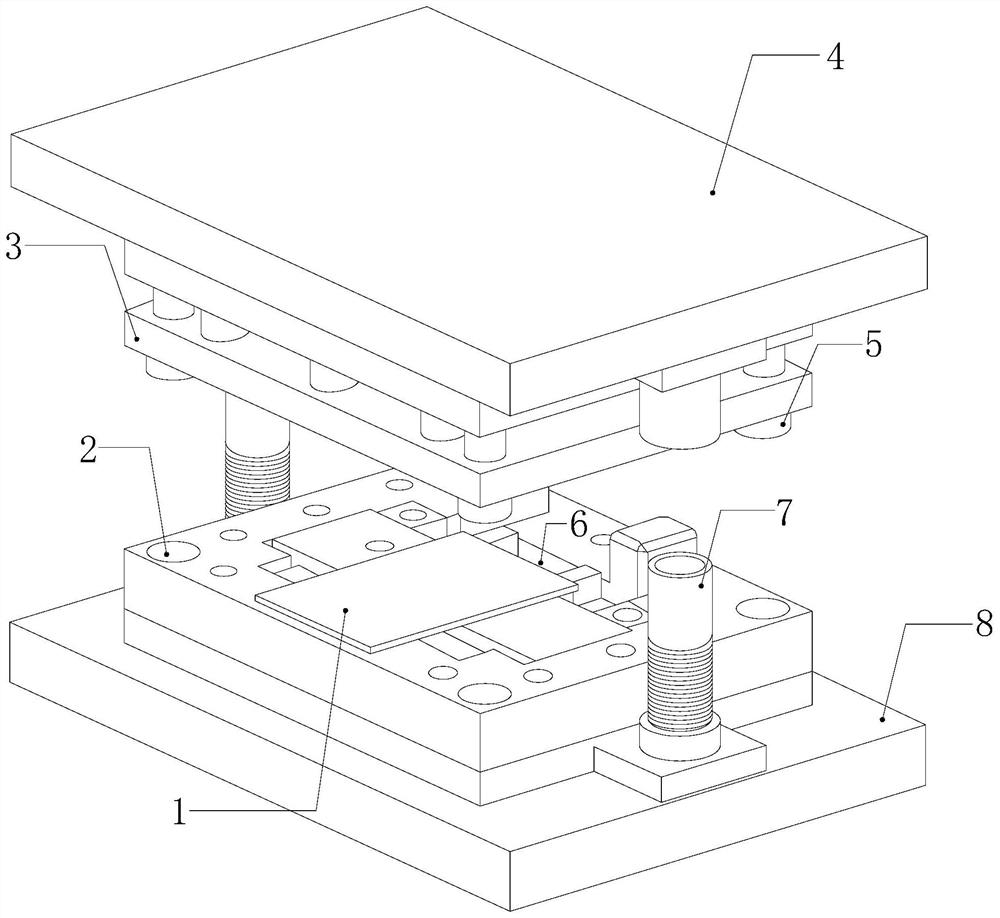

[0029] see figure 1 , the present invention provides a technical solution: a high-power semiconductor device packaging mold molding device, the structure of which includes a lower mold core 1, a docking hole 2, an upper mold core 3, an upper mold 4, a docking rod 5, an ejector device 6, Position bar 7, lower mold 8, described lower mold core 1 is installed on the lower mold 8, is provided with ejection device 6 between described lower mold 8 and lower mold core 1, and described lower mold 8 both sides are all provided with The connecting positioning rod 7, the lower die 8 is connected with the upper die 4 through the positioning rod 7, the upper die 4 is integrated with the upper die core 3, and the upper die 4 is provided with a butt joint rod 5, The docking rod 5 is socketed with the docking hole 2 through the upper mold 4 , and the lower mold core 1 and the upper mold core 3 are closely attached.

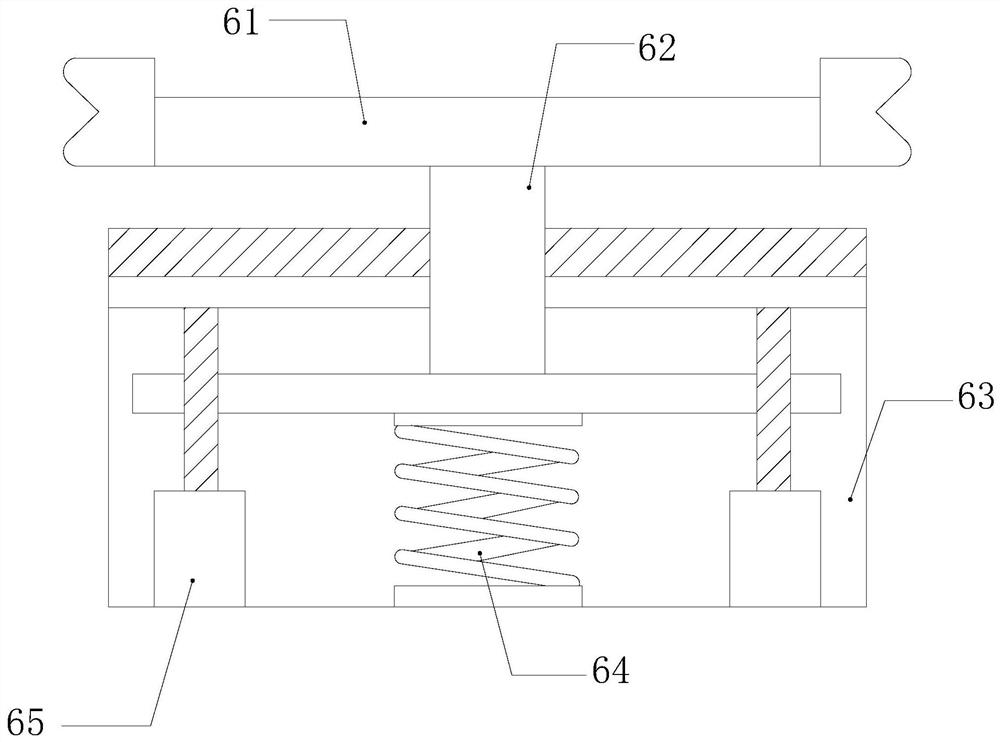

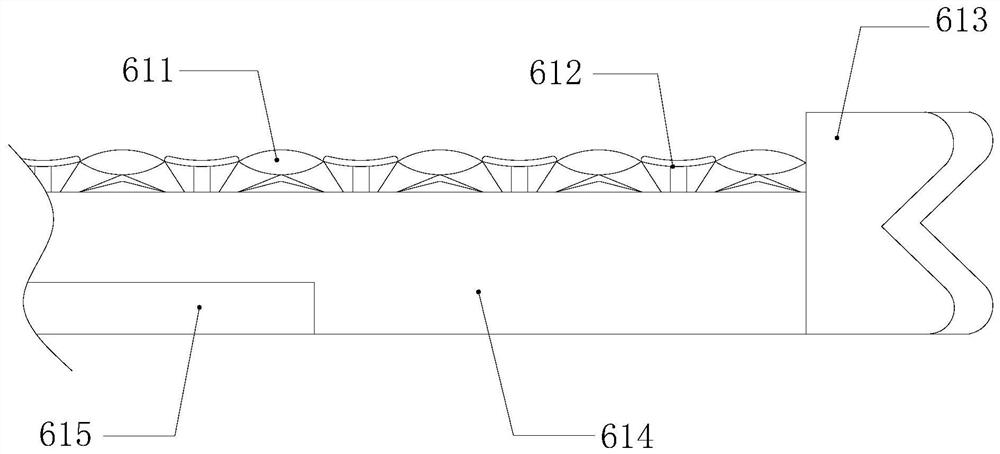

[0030] see figure 2 , the ejector device 6 includes a clamping member 61...

Embodiment 2

[0040] see figure 1 , the present invention provides a technical solution: a high-power semiconductor device packaging mold molding device, the structure of which includes a lower mold core 1, a docking hole 2, an upper mold core 3, an upper mold 4, a docking rod 5, an ejector device 6, Position bar 7, lower mold 8, described lower mold core 1 is installed on the lower mold 8, is provided with ejection device 6 between described lower mold 8 and lower mold core 1, and described lower mold 8 both sides are all provided with The connecting positioning rod 7, the lower die 8 is connected with the upper die 4 through the positioning rod 7, the upper die 4 is integrated with the upper die core 3, and the upper die 4 is provided with a butt joint rod 5, The docking rod 5 is socketed with the docking hole 2 through the upper mold 4 , and the lower mold core 1 and the upper mold core 3 are closely attached.

[0041] see figure 2 , the ejector device 6 includes a clamping member 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com