A waste lithium battery recycling device

A waste lithium battery, recycling technology, applied in battery recycling, waste collector recycling, recycling technology and other directions, can solve the problems of polluting the environment, inconvenient sorting and recycling, and inability to store electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

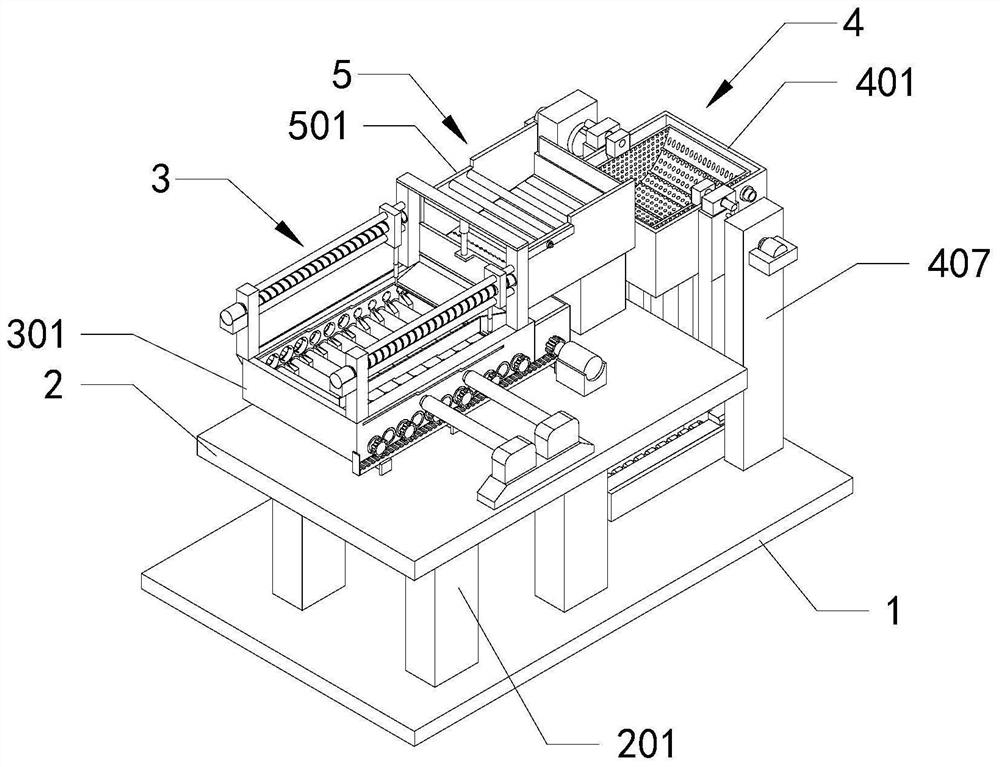

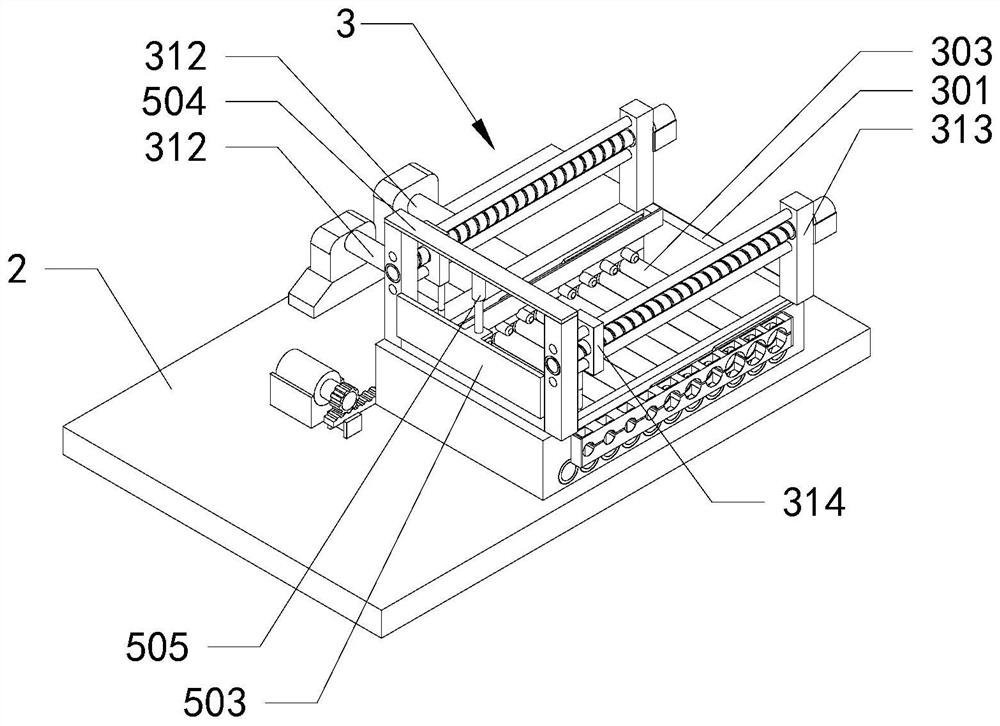

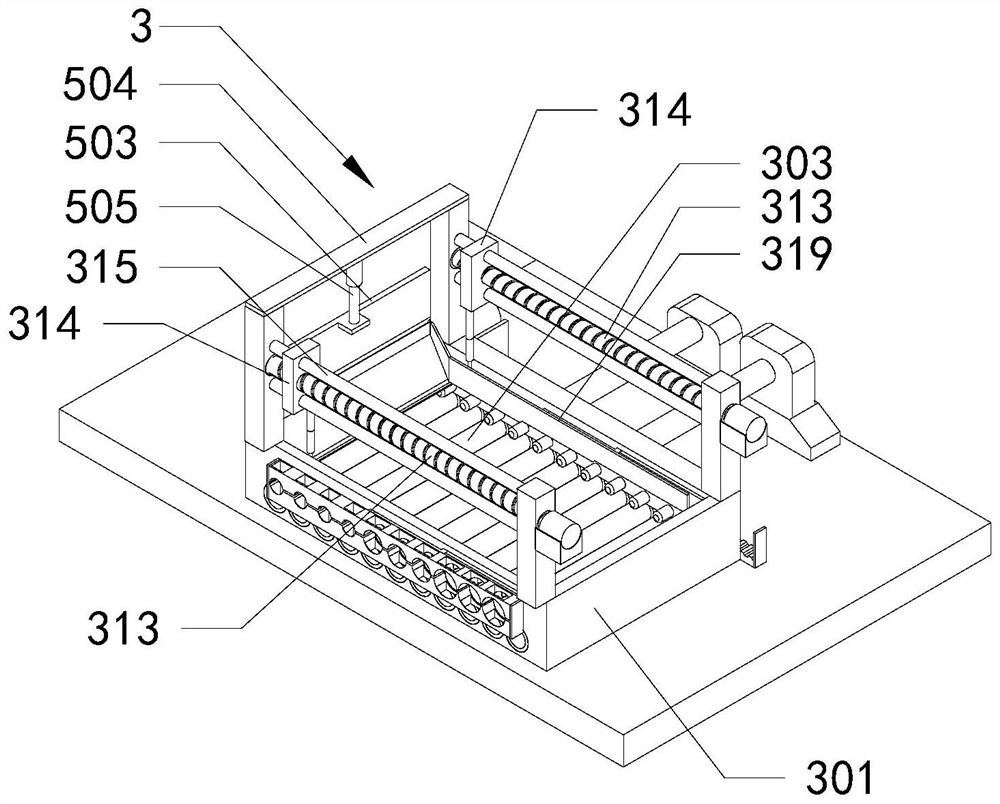

[0040] Please also refer to 1 to Figure 16 , as shown in the figure, this embodiment provides a waste lithium battery recovery treatment device, including: a support base 2 and a stripping mechanism 3, the stripping mechanism is arranged on the support base 2, the stripping mechanism includes a feeding trough 301, The top of one end of the feed trough is provided with a material guide plate 302 extending downwards into the feed trough, and a number of first rotating shafts 303 on the same plane are arranged below the tail end of the material guide plate. The side walls are rotationally connected, and one end of each first rotating shaft extends out of the side wall of the feeding chute at intervals, and one end of the first rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com