An anti-fog and anti-icing ship deck with bionic multi-structure

A ship deck, anti-fog technology, applied in the direction of hull deck, hull, ship construction, etc., can solve the problems of secondary icing, equipment corrosion, time and space limitations, etc., to suppress the formation of fog/ice and prevent fog/ice The formation, probability, and area-reducing effects of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

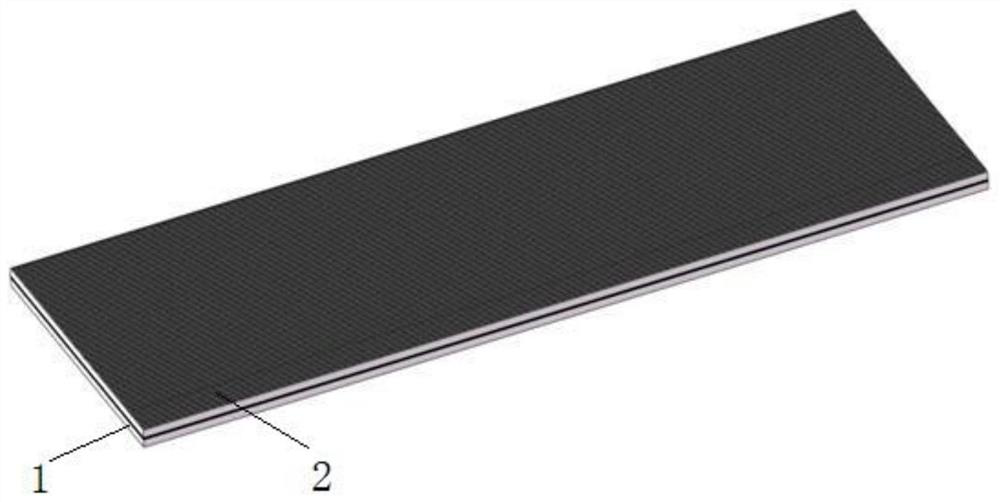

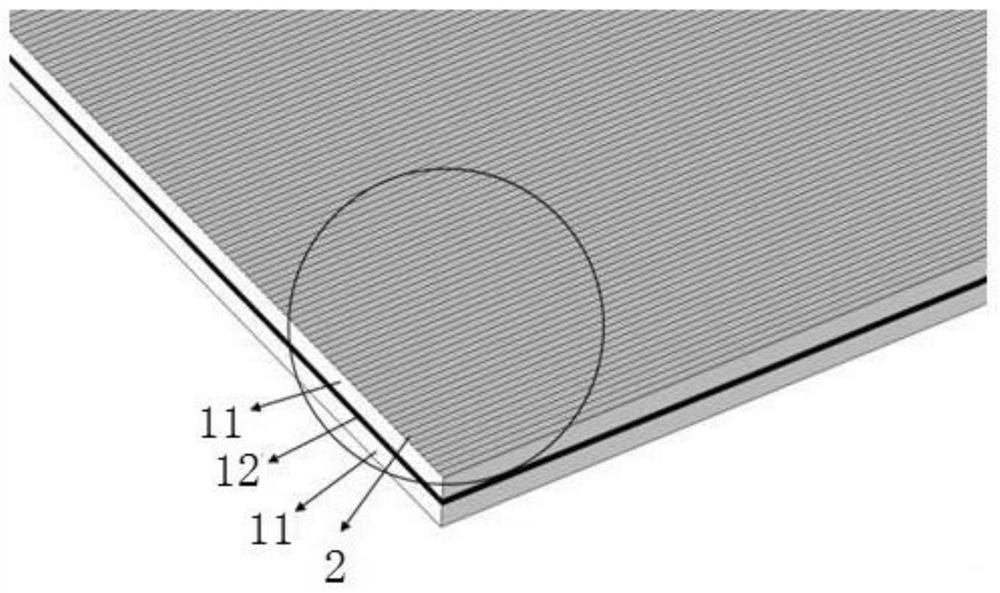

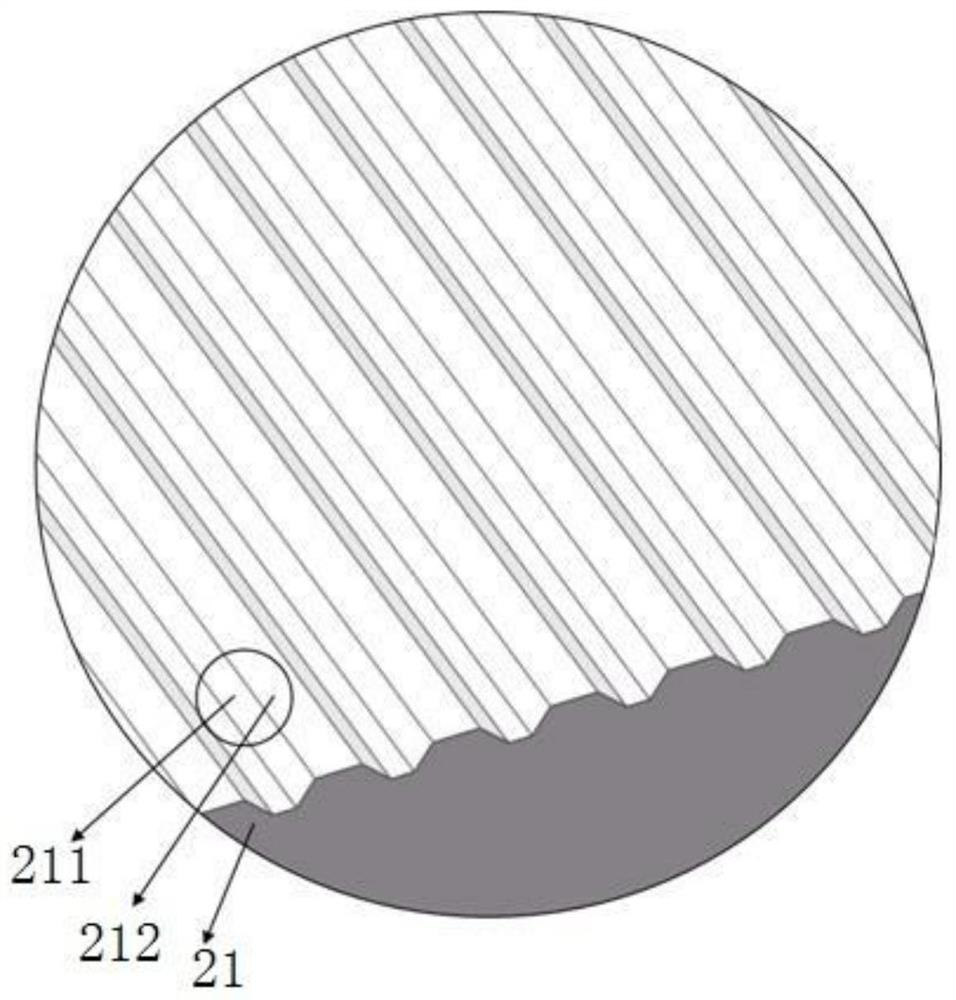

[0020] see figure 1 An anti-fog and anti-ice ship deck with a bionic multi-component structure includes a deck body 1 and a micro-nano structure 2 arranged on the upper surface of the deck body for anti-fog and cold resistance. see figure 2 , the deck body 1 includes upper and lower rigid layers 11 and a flexible layer 12 arranged between the rigid layers 11, the upper and lower rigid layers 11 are made of the same material, the rigid layer 11 is made of metal plate, the main material is iron, nickel and chromium, The flexible layer 12 adopts an aluminum foil rubber-plastic plate, which can maintain the temperature of the upper deck, and also has excellent anti-corrosion effect, prolonging the service life of the deck. The rigid layer 11 and the flexible layer 12 are connected by a phenolic resin adhesive, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com