Serialization device for intelligent jig frame adjustable head

A technology of flexible head and tire frame, which is applied in transportation and packaging, ships, dry docks, etc., can solve the problems of the suitability of the tire frame, redundant arrangement of the tire frame, and short life cycle, so as to improve the layout efficiency and adjust the tire frame. The effect of frame height and precise tire frame height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

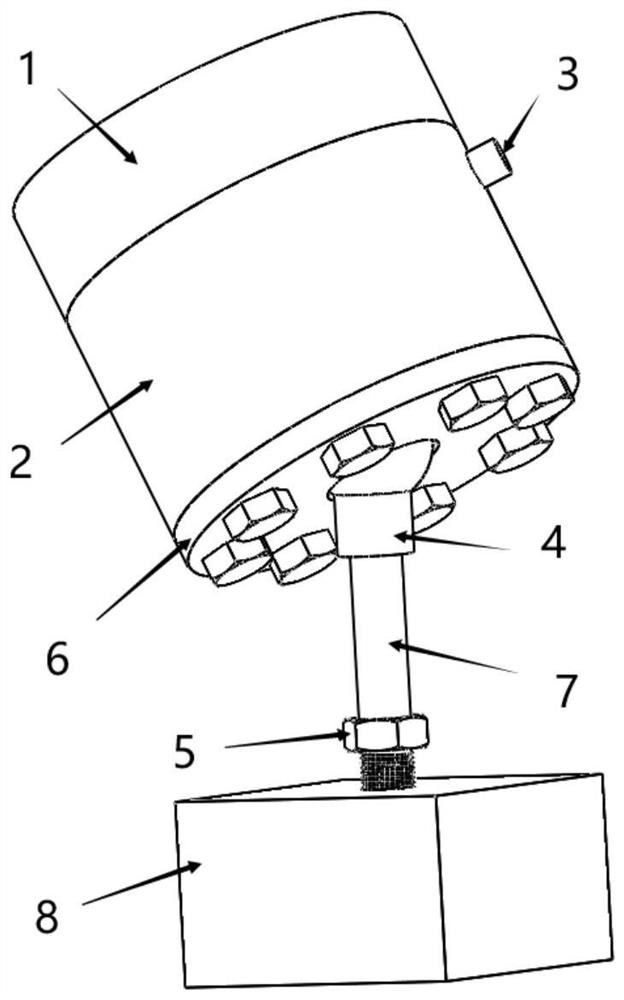

[0047] According to the present invention, a serialized device for an intelligent tire frame flexible head according to the present invention includes a height support device, a contact unit is connected to the upper end of the height support device, and a lower end of the height support device is connected with a contact unit. A tire frame buffer block is connected;

[0048] The height support device is used to connect the tire frame buffer block and the contact unit; the contact unit is composed of a pressure sensor, a support unit 1, an upper end cover 2, a baffle 6, a ball head 4 and a nut 5;

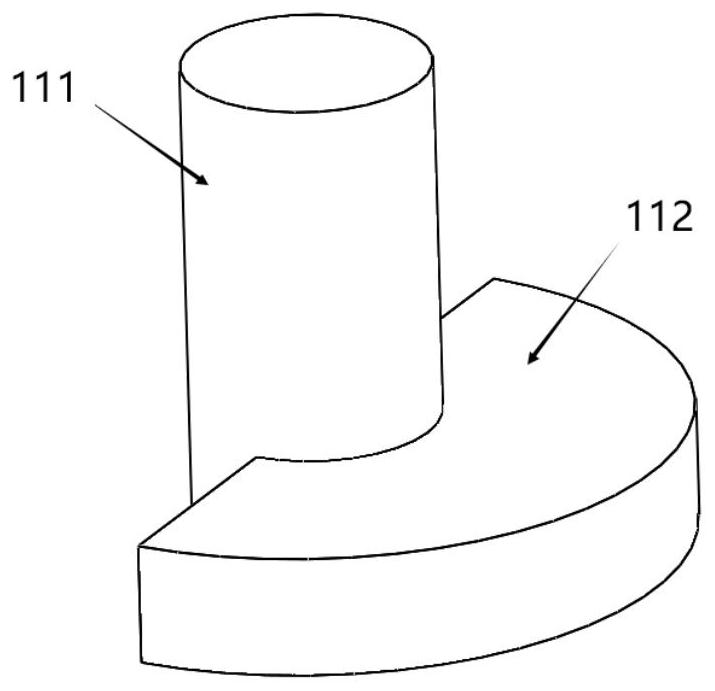

[0049] Specifically, the contact unit includes a support unit 1 with a cylindrical top, an upper end cover 2 installed at the lower part of the support unit 1 , and a baffle plate 6 installed at the lower part of the upper end cover 2 .

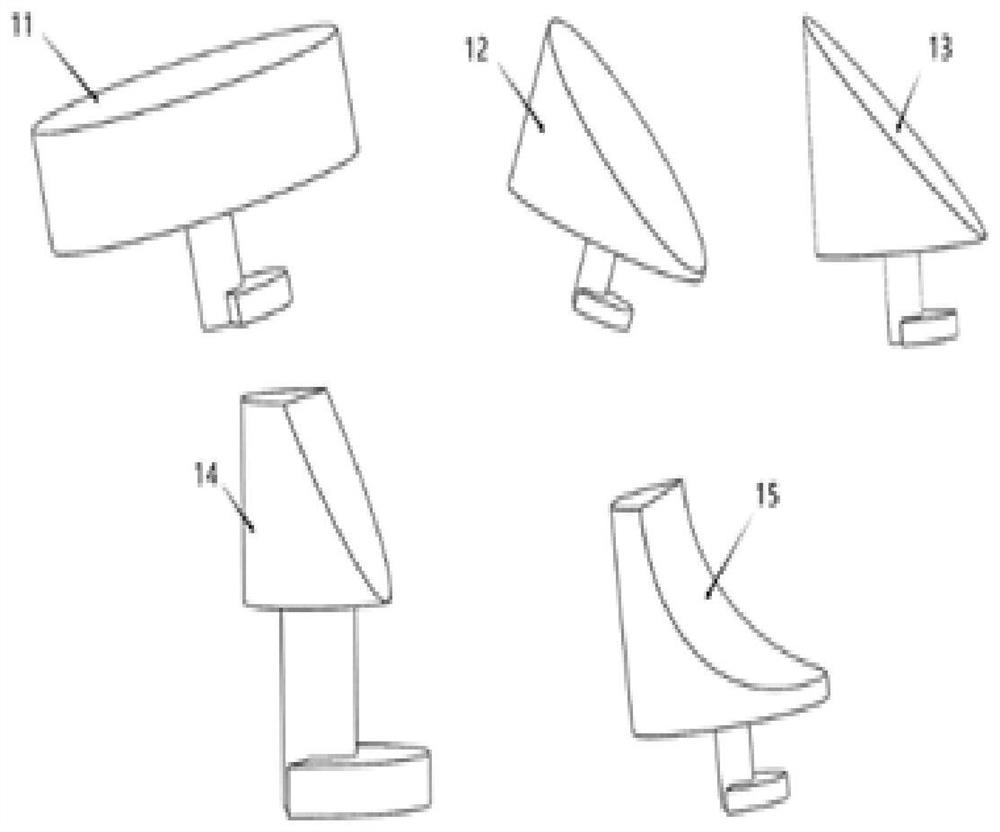

[0050] Further, the planes of different degrees of the support unit 1 are formed by cutting a cylinder; a combination bolt is welded under the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com