Push-pull type transfer robot

A handling robot, push-pull technology, applied in the direction of conveyor objects, transportation and packaging, lifting devices, etc., can solve problems such as low efficiency, equipment coordination hazards, etc., achieve flexible and convenient use, stable and compact overall structure, and increase equipment maintenance and the effect of maintenance space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

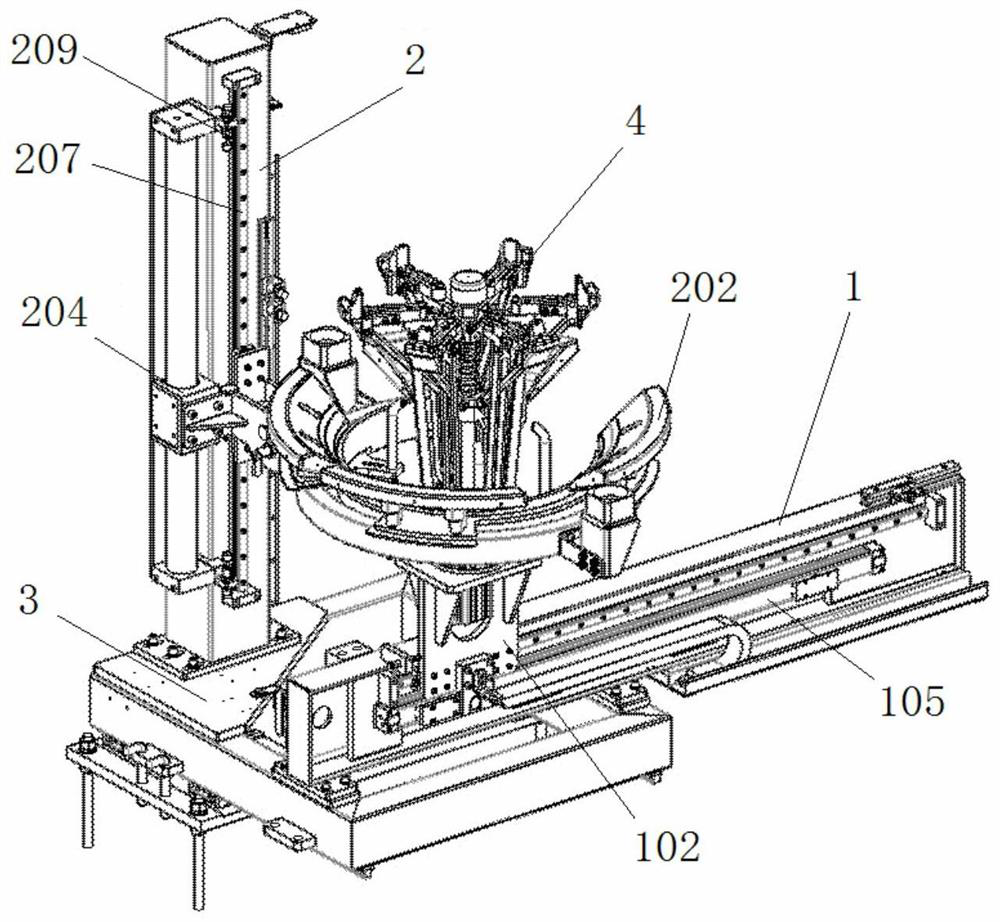

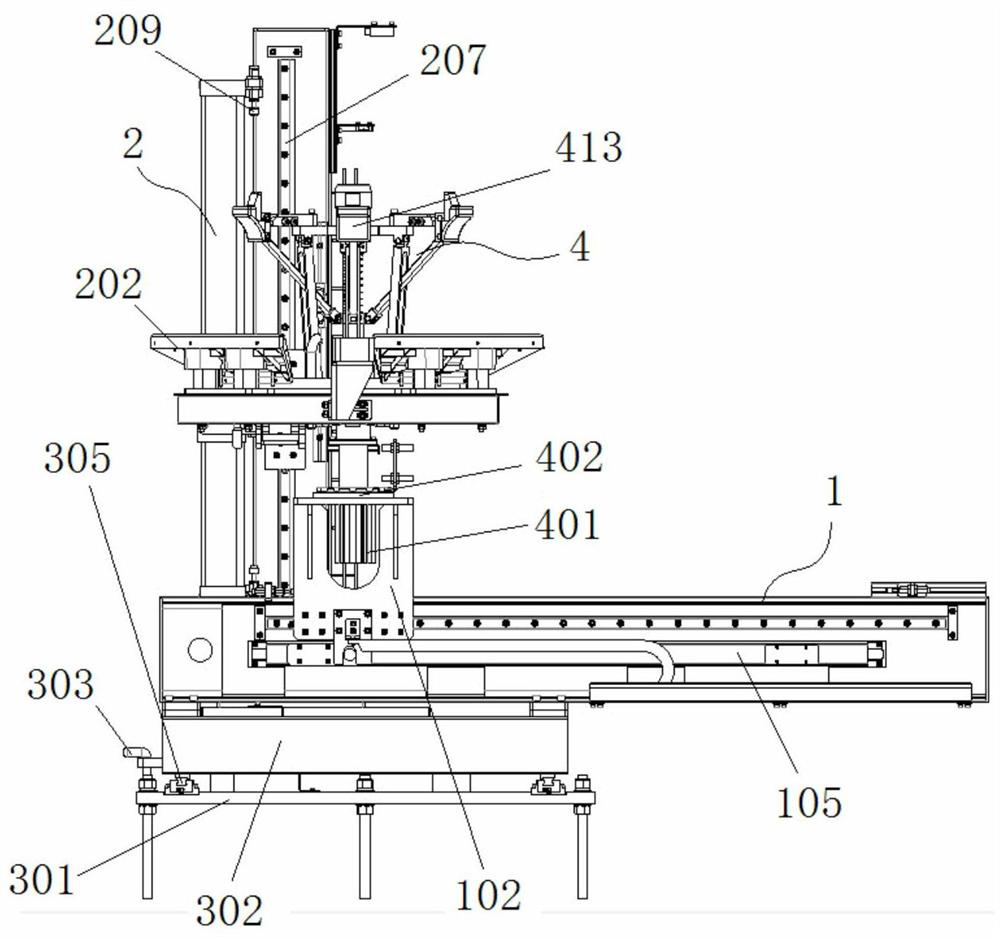

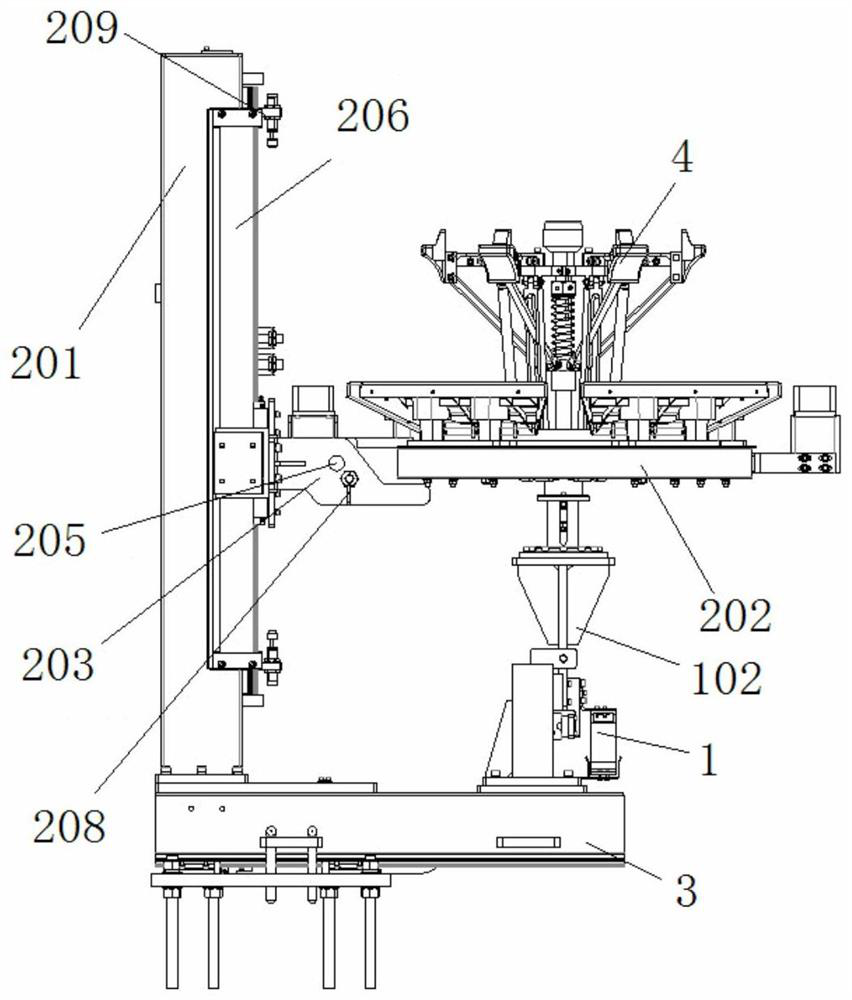

[0031] Such as Figure 1-9 As shown, the present invention includes a base 3, a grip assembly 4, a grip walking mechanism 1 and a cargo lifting mechanism 2, the grip walking mechanism 1 and the cargo lifting mechanism 2 are both arranged on the base 3, and the grip assembly 4 is installed on The gripper walking mechanism 1 is driven to move horizontally by the gripper walking mechanism 1. The cargo lifting mechanism 2 is provided with a cargo tray 202 that can be lifted vertically and has a gap on one side, and the gripper assembly 4 passes through the gripper. The hand traveling mechanism 1 is driven to move out of the loading tray 202 by the gap.

[0032] Such as Figure 1~5 As shown, the grip walking mechanism 1 includes a travel driving cylinder 105, a grip support 102 and a mounting seat 101, wherein the mounting seat 101 is fixed on the base 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com