Braid material testing method and testing system

A test method and material technology, applied in general control system, control/regulation system, environment/reliability test, etc., can solve the problems of uncontrolled, low test efficiency of digital bridge, poor rejection, etc., to solve the problem of feeding , Eliminate the time of manually pulling the tape, and solve the effect of low test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

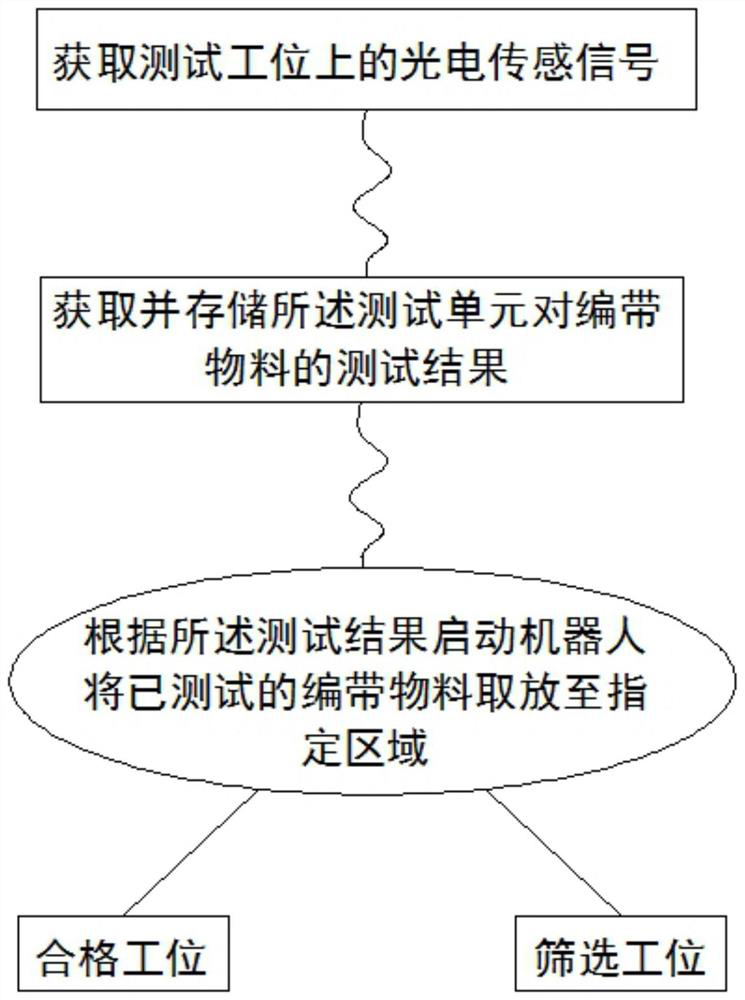

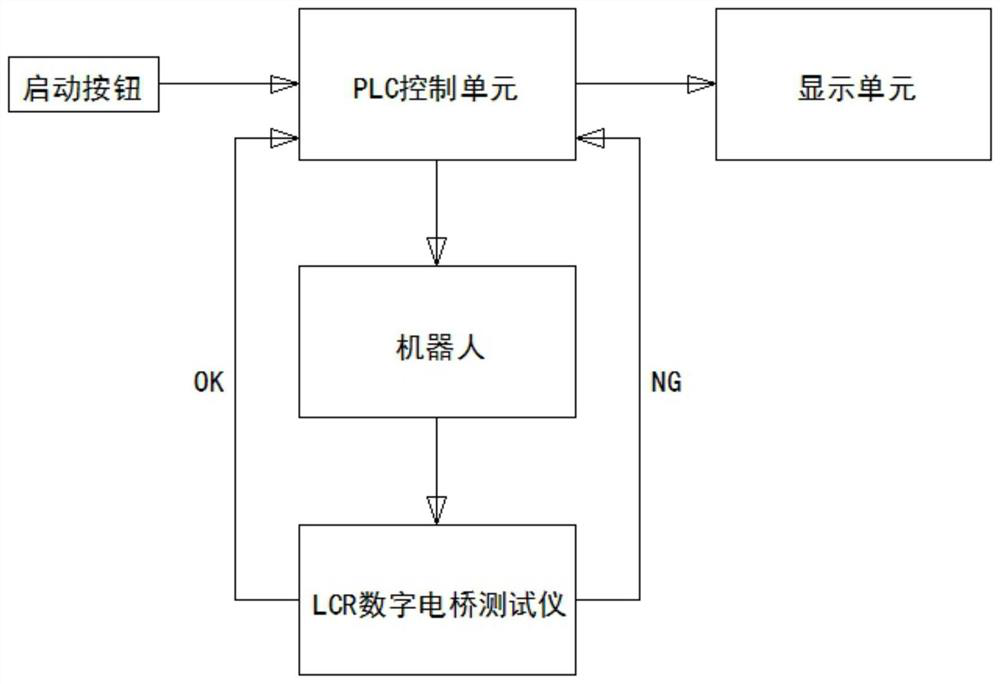

[0043] Before starting, prepare the braided material on the area to be tested. You can manually put the braided material into a specific material box, press the button to send a start signal, start the PLC control unit, and control the robot's pick-and-place jig and detection jig to run. The tape material is picked up by the robot through the clamping fixture in the area to be tested and put into the test station. The test unit first tests the top layer of the tape material;

[0044] Control the detection fixture of the robot to locate and fix the braiding material to be tested, and the contact between the thimble and the braiding material triggers the photoelectric switch to generate a photoelectric sensing signal, and then starts the LCR digital bridge tester to test the braiding material;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com