Bistable electromagnetic system applied to contactor and contactor thereof

An electromagnetic system and bistable technology, applied in the direction of electromagnetic relays, electromagnetic relay details, circuits, etc., can solve the problems of complex structural design of electromagnetic systems, many assembly parts, high material costs, etc., to improve performance and market competition Power, short energization time, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

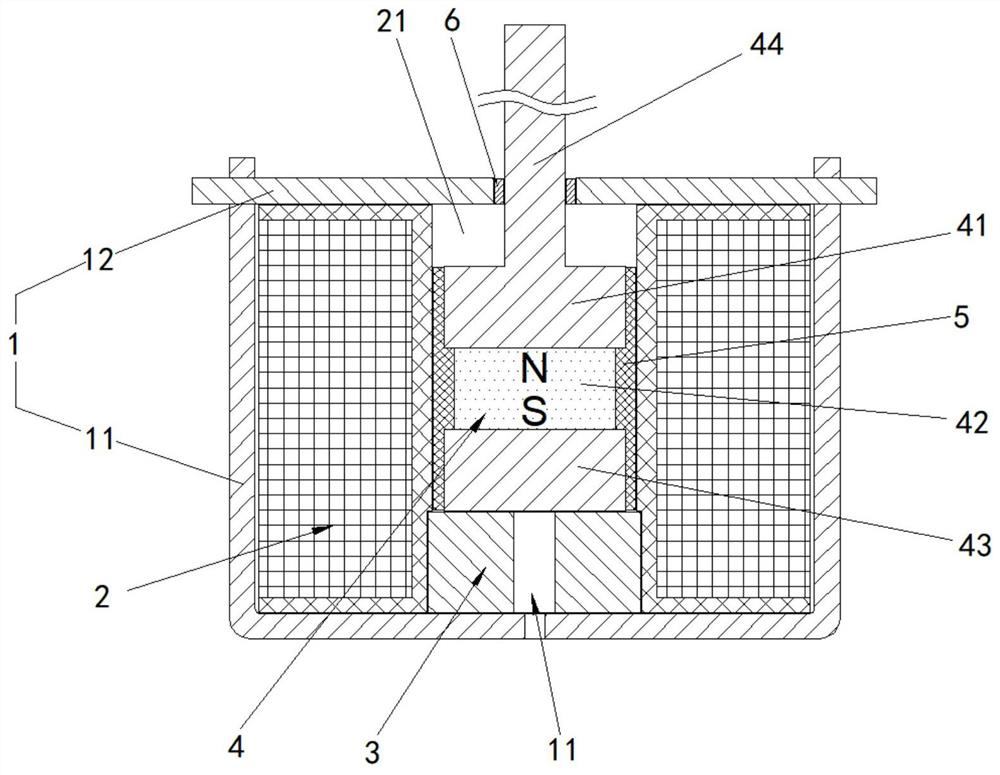

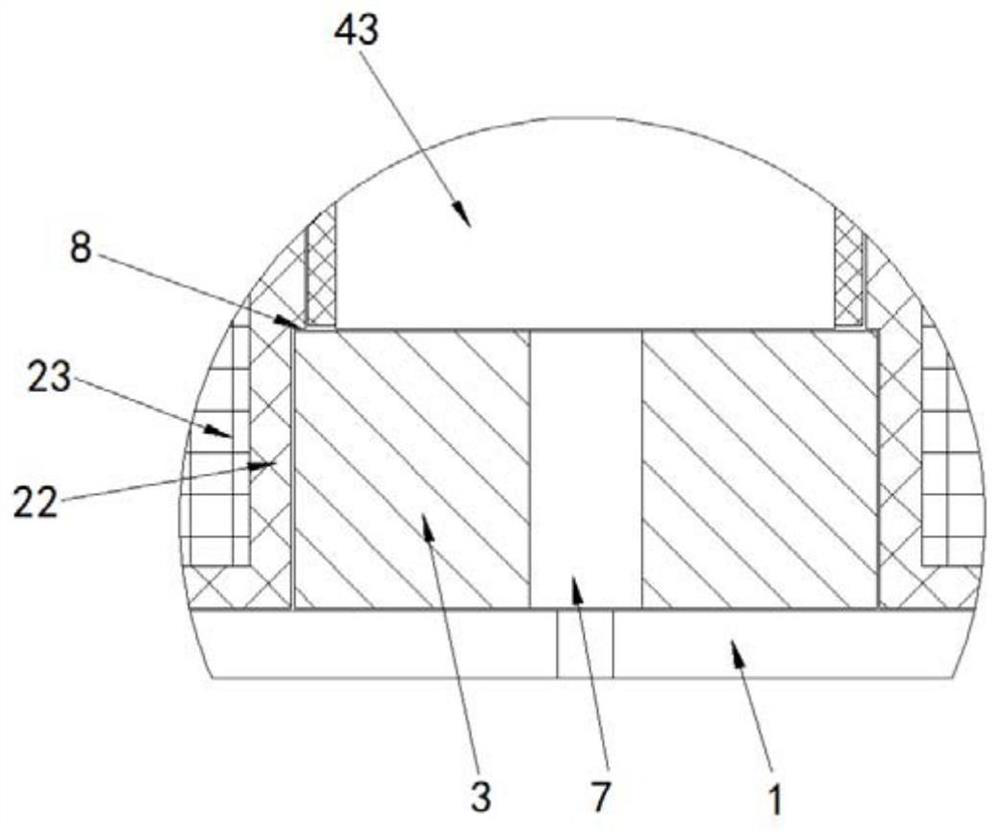

[0040] This embodiment provides as Figure 1-5 A bistable electromagnetic system applied to a contactor is shown, comprising: a yoke frame 1 with a closed installation space;

[0041] The coil structure 2 is installed in the installation space, and includes a middle cavity 21 extending along its axial direction, and the two ends of the middle cavity 21 are respectively limited to the upper and lower ends of the yoke frame 1;

[0042] The magnetic pole 3 is fixed in the middle cavity 21 and connected with the lower end of the yoke frame 1;

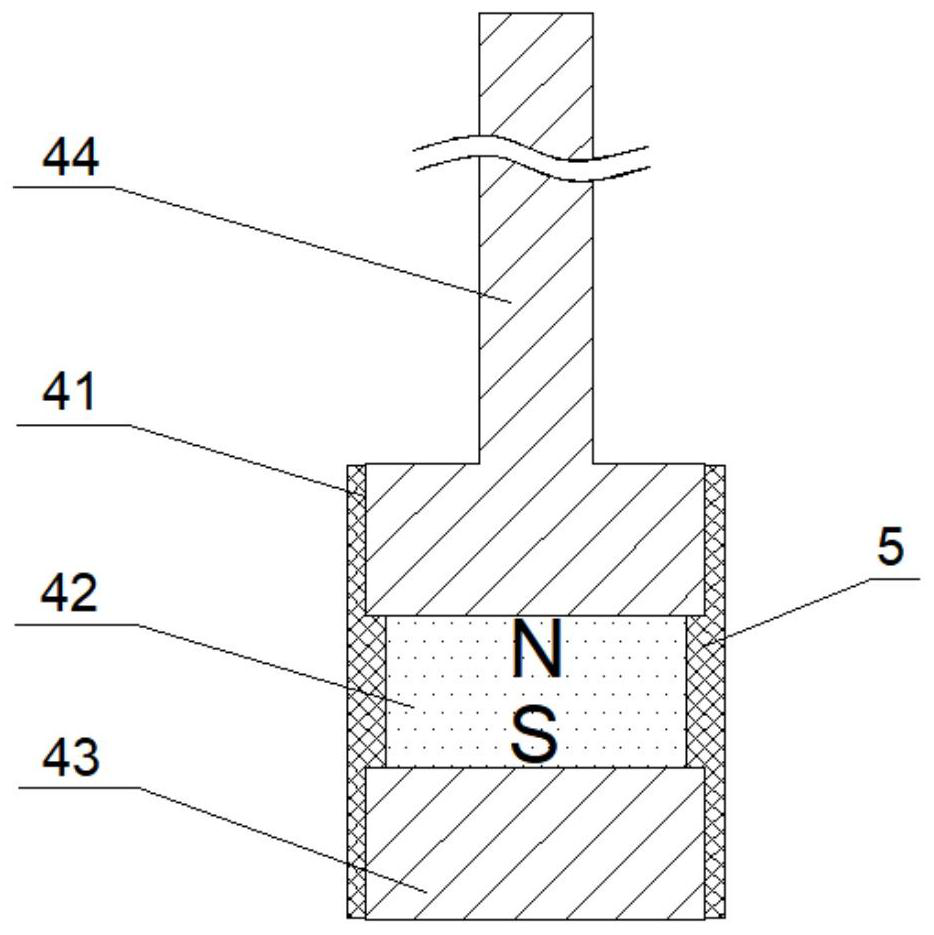

[0043] The moving iron core assembly 4 is movably arranged in the middle cavity 21, and it includes an upper iron core 41, a permanent magnet 42 and a lower iron core 43 which are successively connected along the axial direction of the middle cavity 21, and the upper iron core 41. The permanent magnet 42 and the lower iron core 43 are integrally formed by injection molding. The upper iron core 41 has a drive rod 44 extending out of the upp...

Embodiment 2

[0055]This embodiment provides a contactor, including the bistable electromagnetic system applied to the contactor described in Embodiment 1. The contactor of this embodiment is provided with the above-mentioned bistable electromagnetic system, which naturally has All the advantages brought by the above-mentioned bistable electromagnetic system, the bistable electromagnetic system is connected with the moving contact assembly of the contactor through the driving rod 44 of the moving iron core assembly 4, and plays the role of transmitting motion and force between the two , when the moving iron core assembly 4 moves up and down in the coil structure 2, the contact and separation of the moving contact assembly and the static contact assembly are realized, the response speed is fast, the noise is low, the power consumption is low, and the performance and performance of the contactor are improved. electrical life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com