Rotary magnetic force frequency modulation type laminated efficient piezoelectric energy harvester

A piezoelectric energy harvesting and rotating technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve low energy harvesting efficiency and limited space utilization , rotating machinery energy harvesting and frequency modulation method is single, etc., to achieve the effect of high energy harvesting efficiency, novel structure and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

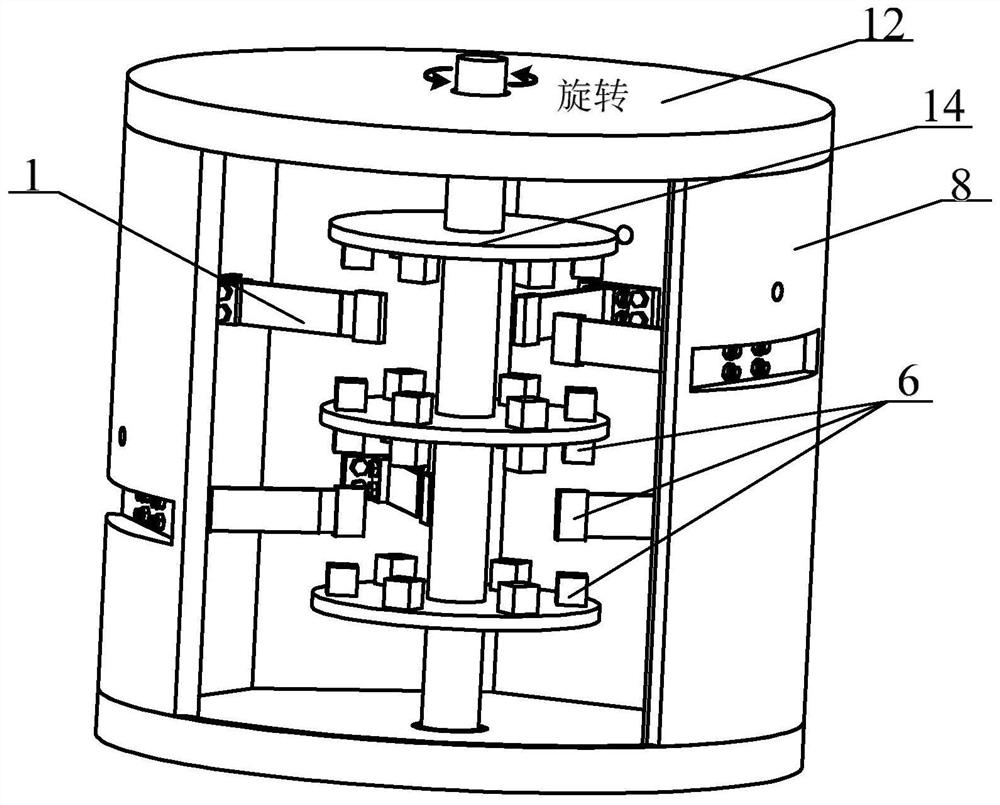

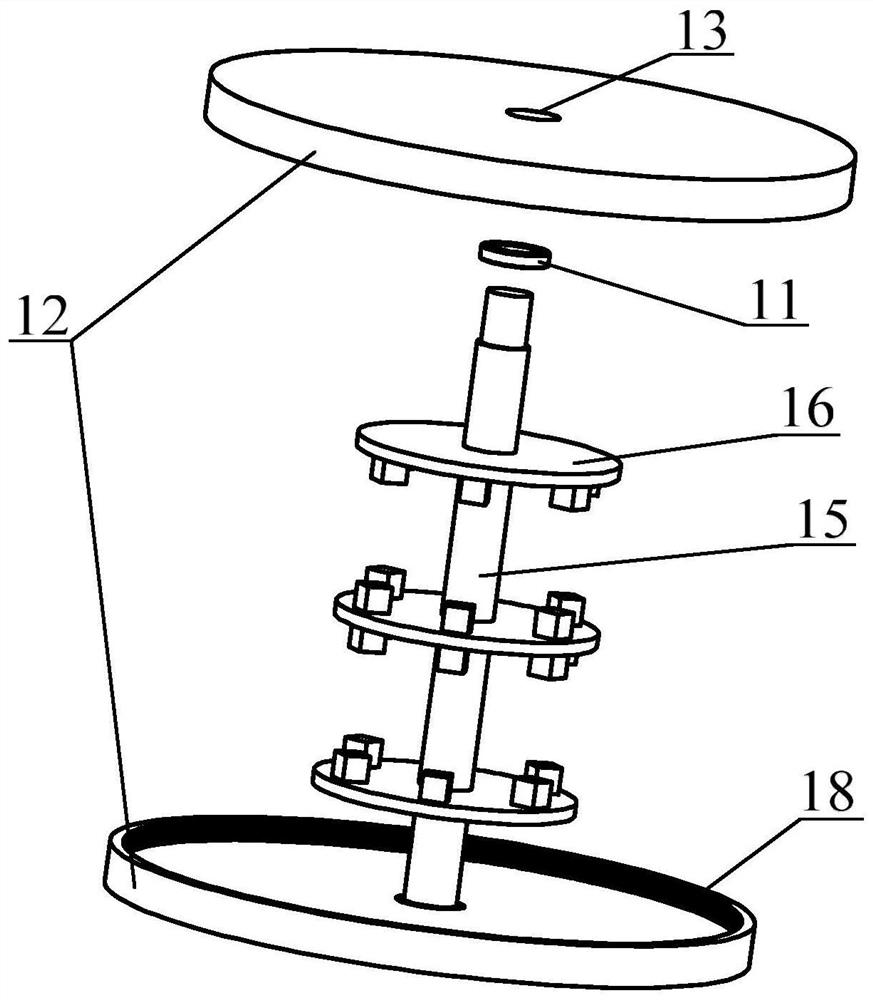

[0028] Such as Figure 1 to Figure 6 As shown, a rotary magnetic frequency modulation stacked high-efficiency piezoelectric energy harvester described in the present invention includes a piezoelectric cantilever beam 1, a rotating disc 14, a cover plate 12, a cylinder 8, and a magnet 6 assembly;

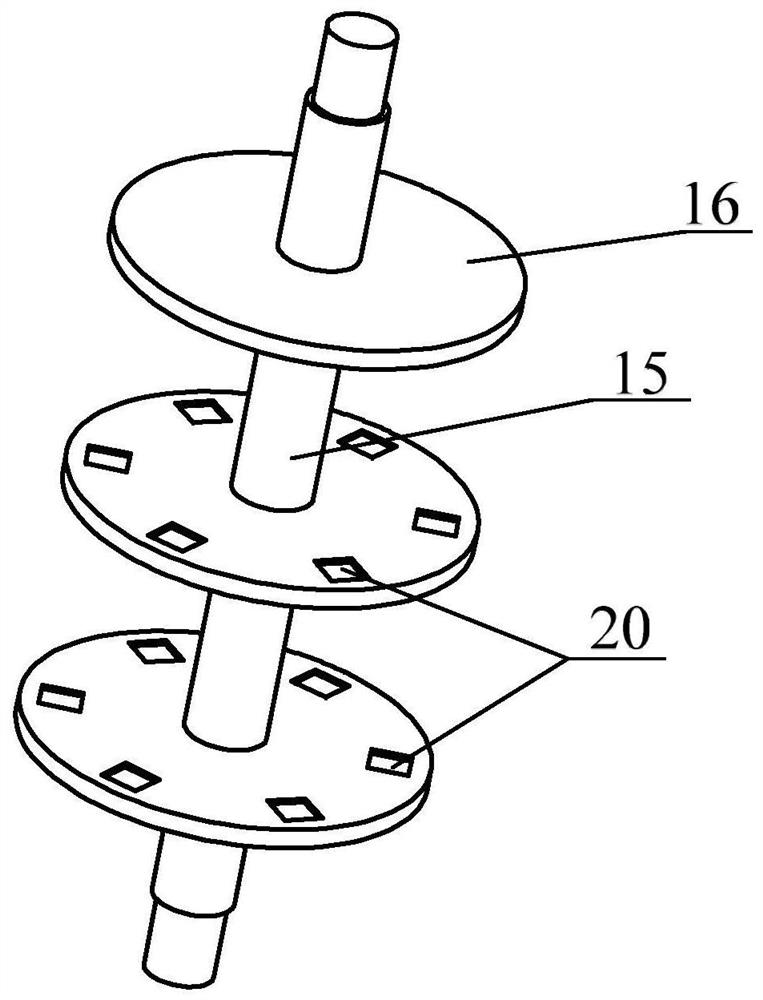

[0029] The piezoelectric cantilever beam 1 is fixedly connected to the cylinder 8 through bolts and nuts and the splint 5, the cylinder 8 and the cover plate 12 are connected by threads, and the rotating shaft 15 of the rotating disk 14 is coaxial with the center hole 13 of the cover plate through the bearing 11 To connect, the magnets 6 are uniformly pasted on the disc 16 of the rotating disc 14 in the circumferential direction.

[0030] Further: the piezoelectric cantilever beam 1 includes an elastic matrix 3 and a piezoelectric material 2, the pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com