Rotary exhaust fume collecting hood for oil fume purification

A technology for oil fume purification and fume collection hoods, which is applied in the direction of smoke removal, chemical instruments and methods, cleaning methods and utensils, etc. It can solve the problems of complex opening and closing structures of oil fume collection hoods, and does not use fast processing operations to achieve rapid opening Closing, convenient in and out of materials, improving the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

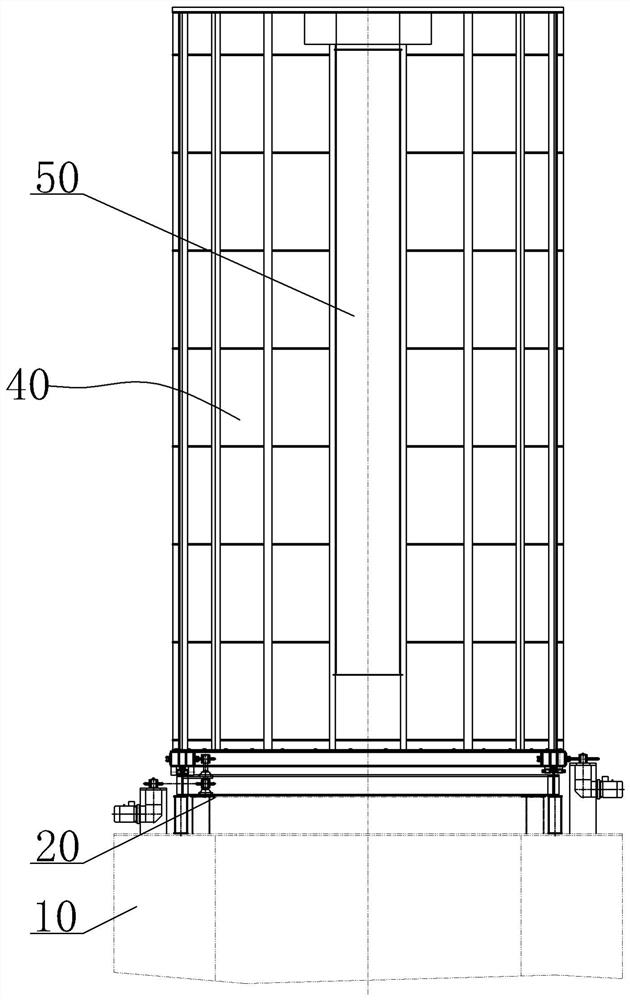

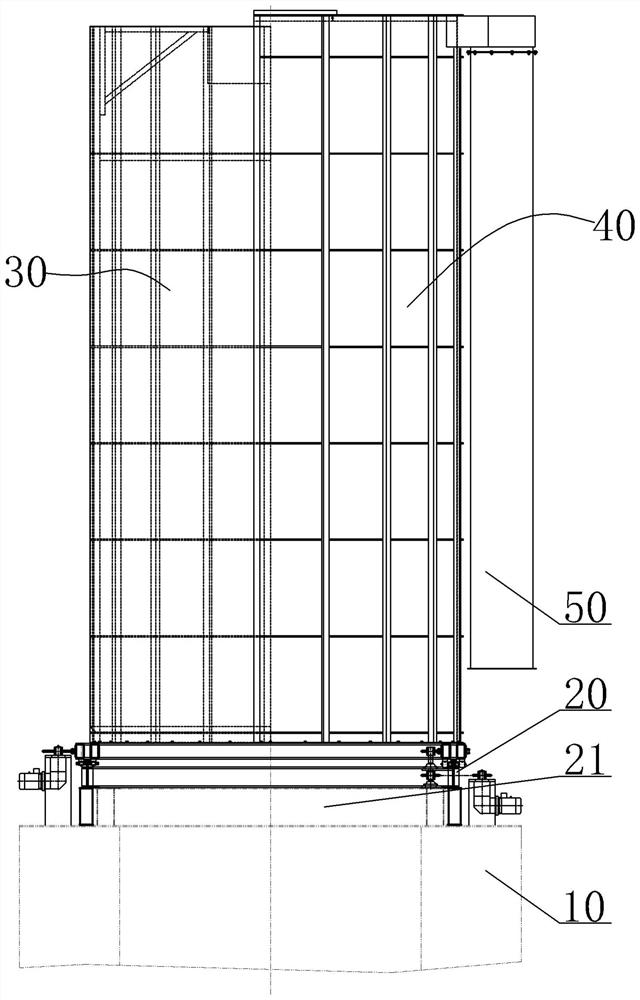

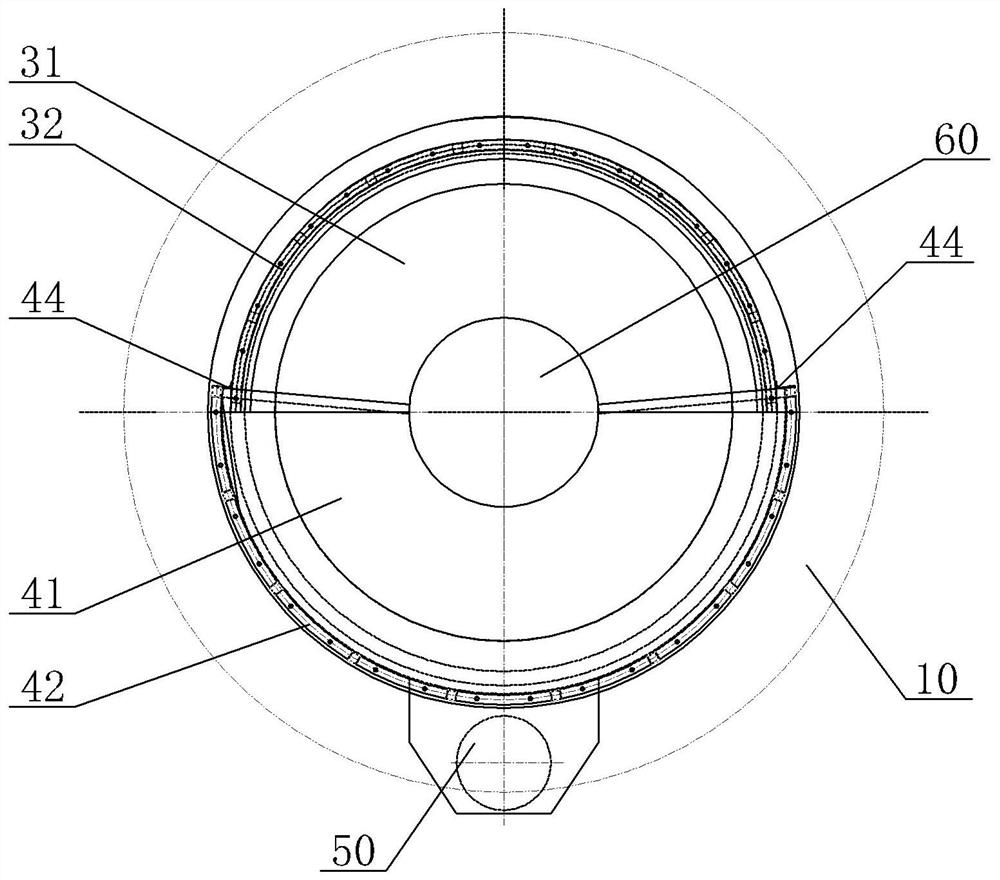

[0033] A kind of oil fume purification rotary fume collection hood, see Figure 1-Figure 6 , which is arranged in the upper area of the quenching oil tank 10, which includes: a mounting base 20, the mounting base 20 is fixed on the upper ring surface of the quenching oil tank 10;

[0034] An inner shield 30, the inner shield 30 includes a first annular top baffle 31 at the top and a semicircular arc-shaped first shroud 32 on the outer periphery;

[0035] An outer shield 40, the outer shield 40 includes a top second ring-shaped top baffle 41 and a semicircular arc-shaped second shroud 42 on the outer periphery;

[0036] The center of the mounting base 20 is a through hole 21, which facilitates the passage of oil and gas. The annular upper surface of the mounting base 20 is respectively provided with a first guiding circular track groove 22 and a second guiding circular groove 22 through a baffle structure 24. Shaped track groove 23, the first guide circular track groove 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com