Auxiliary grinding device for ground grinding machine

A grinding machine and ground technology, which is applied to machine tools suitable for grinding workpiece planes, grinding drive devices, grinding machine parts, etc. achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

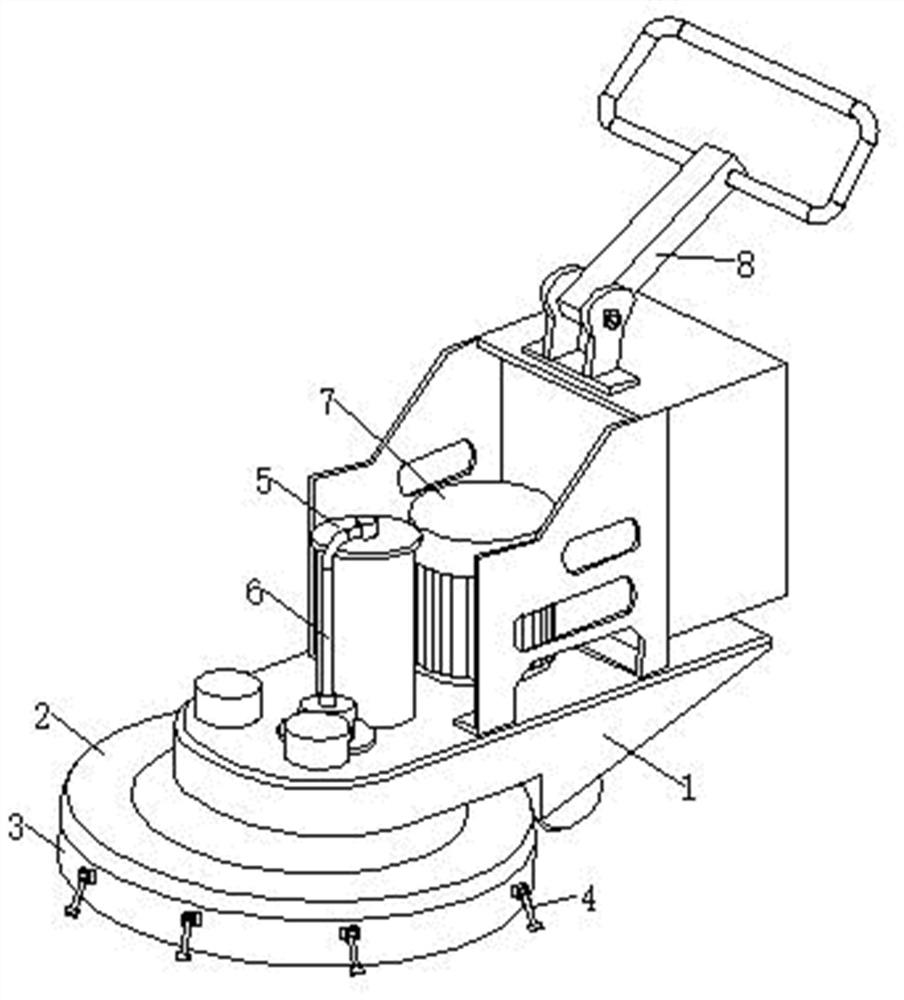

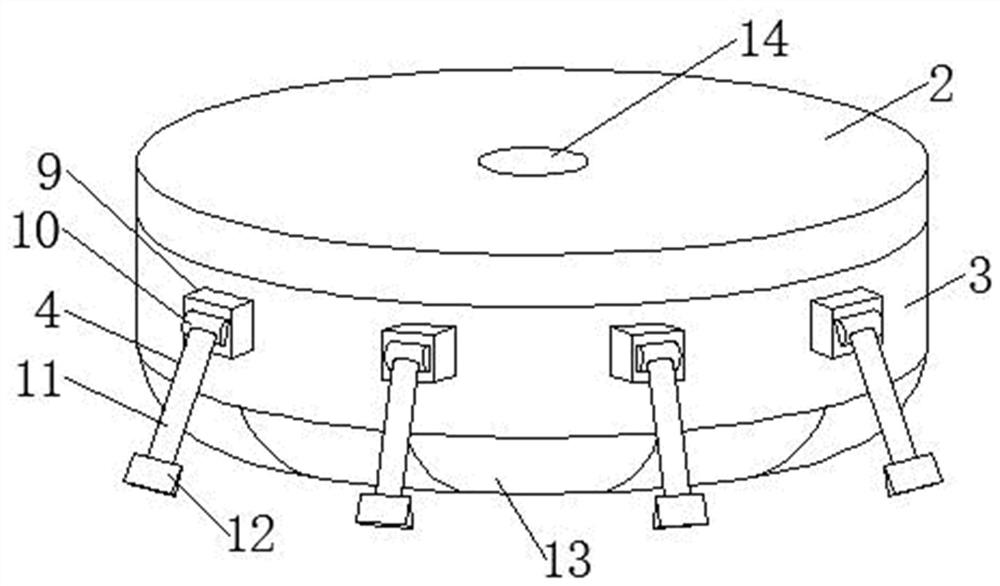

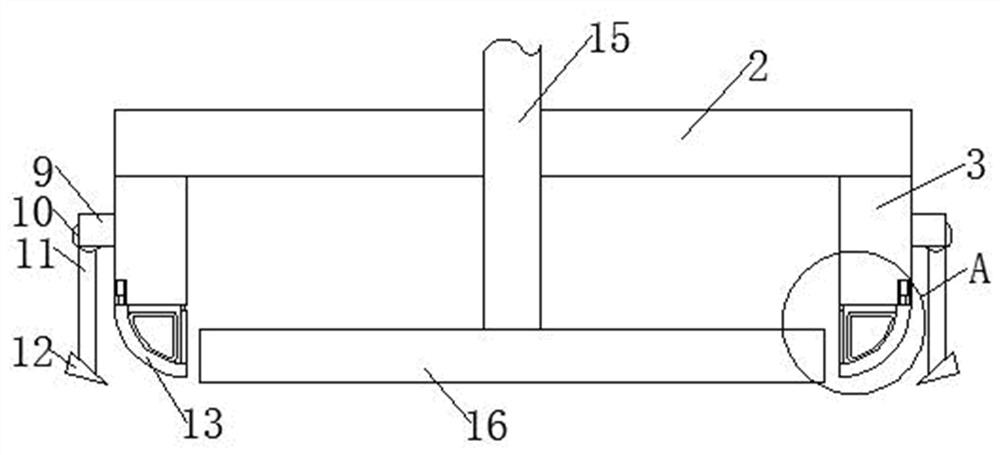

[0030] like Figure 1-6 As shown, an auxiliary grinding device for a ground grinding machine comprises a body (1), a circular cover plate (2) is installed at the front end of the bottom of the body (1), and a lower surface of the circular cover plate (2) is installed There is an annular plate (3), an auxiliary support plate (13) is installed at the bottom of the annular plate (3), and a plurality of auxiliary support plates (13) are symmetrical about the center of the annular plate (3), and the circular cover plate (2) A polishing sheet (16) is arranged on the lower end surface of the ring plate (3), a support mechanism (4) is installed on the outer side of the annular plate (3), and a blower (5) and a motor (7) are installed on the top of the body (1).

[0031]A first telescopic rod (18) is installed on the top of the side of the auxiliary support plate (13) away from the polishing sheet (16), and a cavity (17) is opened at the bottom of the annular plate (3), and the inner w...

Embodiment 2

[0036] like Figure 1-6 As shown, an auxiliary grinding device for a ground grinding machine comprises a body (1), a circular cover plate (2) is installed at the front end of the bottom of the body (1), and a lower surface of the circular cover plate (2) is installed There is an annular plate (3), an auxiliary support plate (13) is installed at the bottom of the annular plate (3), and a plurality of auxiliary support plates (13) are symmetrical about the center of the annular plate (3), and the circular cover plate (2) A polishing sheet (16) is arranged on the lower end surface of the ring plate (3), a support mechanism (4) is installed on the outer side of the annular plate (3), and a blower (5) and a motor (7) are installed on the top of the body (1).

[0037] A first telescopic rod (18) is installed on the top of the side of the auxiliary support plate (13) away from the polishing sheet (16), and a cavity (17) is opened at the bottom of the annular plate (3), and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com