Automatic walking rail web derusting machine with guiding function and adjustable compensation abrasion loss

An automatic walking and adjustable technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of track grinding damage, uneven grinding amount, poor adjustment, etc., to ensure uniformity and ensure the effect of grinding and rust removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

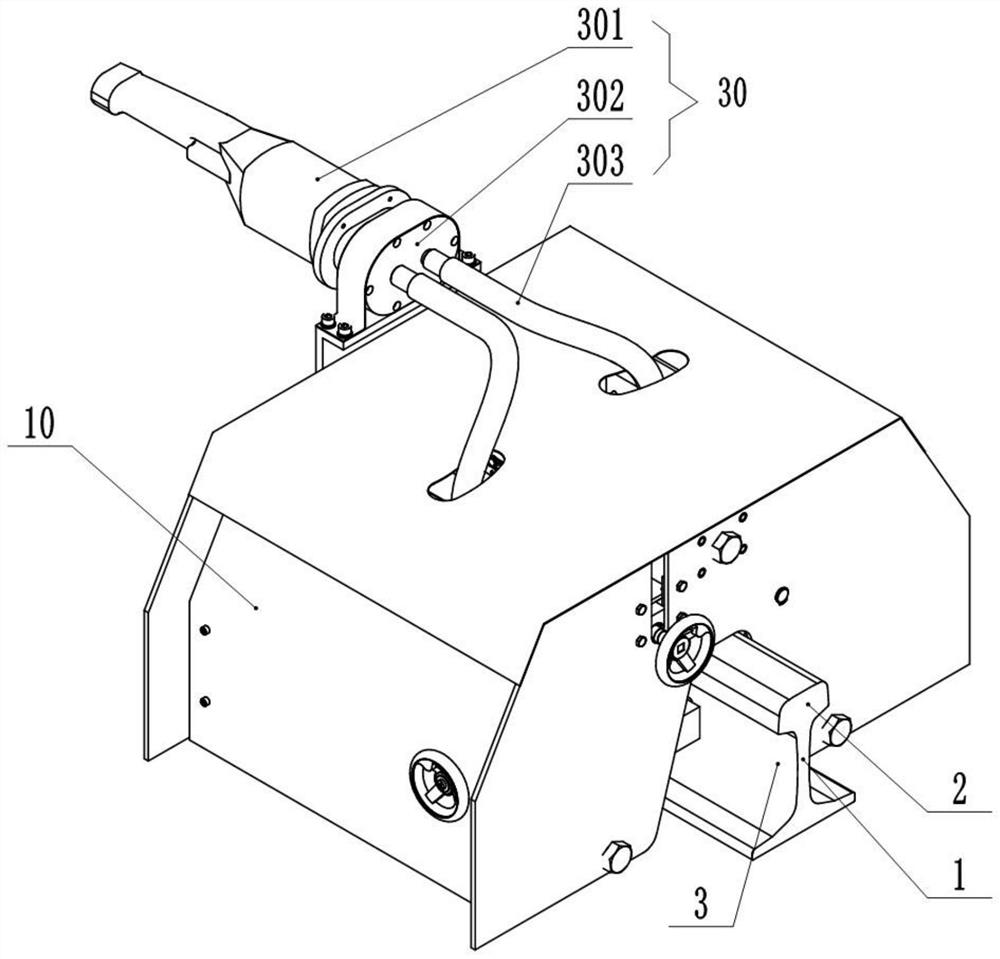

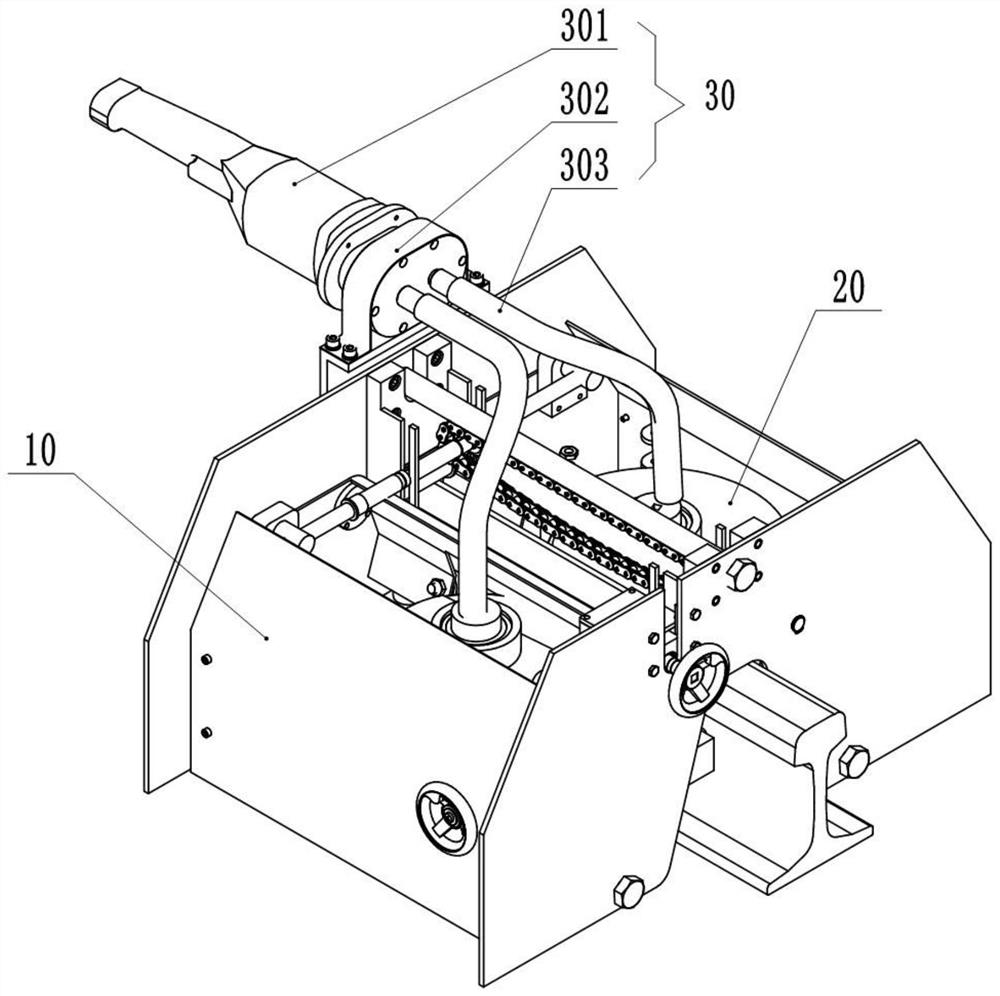

[0036] The embodiment is basically as figure 1 and figure 2 As shown, an automatic walking rail waist derusting machine with guides and adjustable wear compensation includes a walking system 10, a grinding wheel system 20 and a driving system 30, wherein the grinding wheel system 20 is installed in the walking system 10, and the driving system 30 drives the grinding wheel The grinding wheel disc 231 in the system 20 rotates, and makes the walking system 10 automatically move forward along the rail 1; the specific method is as follows:

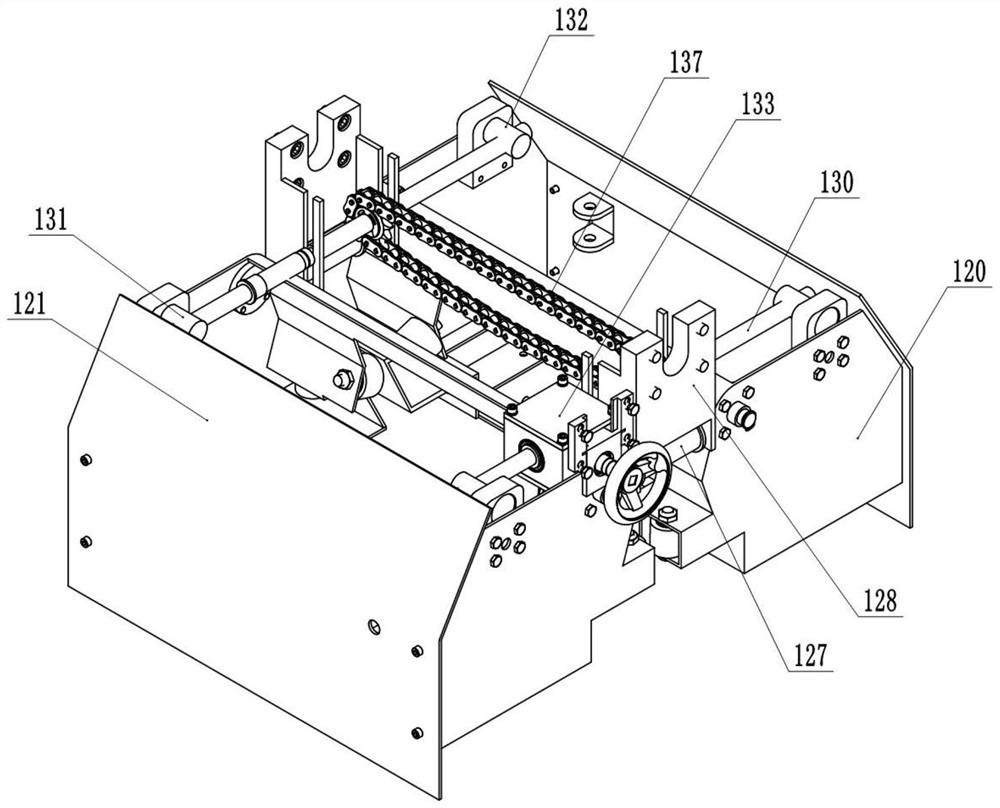

[0037] combine figure 2 and image 3 As shown, the walking system 10 includes an outer cover assembly, a drive assembly and two guide assemblies, wherein the outer cover assembly is combined Figure 4As shown, it includes a top plate 110 and side plates 111 respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com