Device for measuring peeling force of welded nut and welded bolt

A measuring device and welding nut technology, which is applied in the measuring device, the measurement of the property force of piezoelectric devices, the use of mechanical devices, etc., can solve the problem of high frequency of welding strength testing, affecting production efficiency, and inability to achieve rapid detection, etc. problems, to achieve the effect of improving production efficiency, convenient operation and ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, invention is described in further detail.

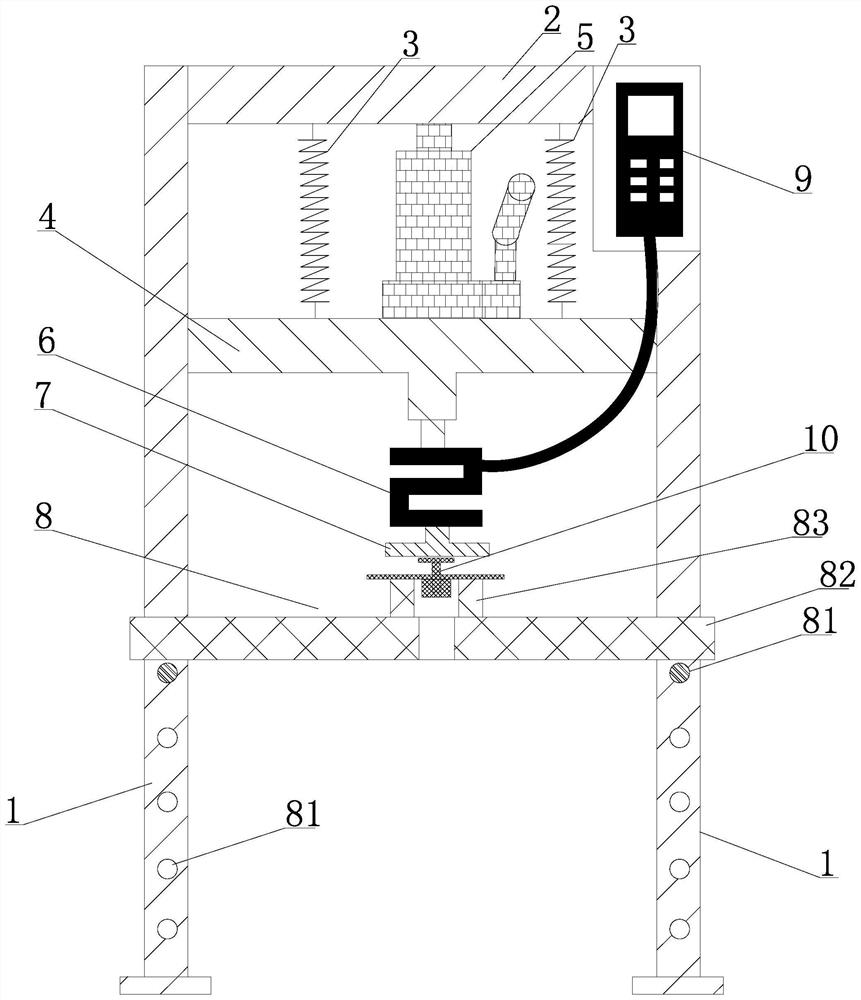

[0010] Such as figure 1 Shown, a kind of measuring device that is used for welding nut bolt stripping force, comprises two parallel support frame 1, the top plate 2 that is provided with between two parallel support frame 1 tops, is provided with on top plate 2 inner side Spring 3, a slider 4 provided on the end of the spring 3, a jack 5 provided between the top plate 2 on one side of the spring 3 and the slider 4, an S-shaped external jack provided on the bottom of the slider 4 Sensor 6, the detection block 7 that is provided with on the S-type external sensor 6, the lifting workbench 8 that is provided with between two parallel support frames 1 below the detection block 7 and is provided with S-type on the top plate 2 A force gauge 9 connected to the external sensor 6 and a detection workpiece 10 provided between the detection block 7 and the lifting table 8 . Lifting workben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com