Rectification system starting control method and system based on DCS (Distributed Control System)

A technology of DCS system and rectifier system, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of low start-up efficiency and inaccurate start-up control of rectifier system, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

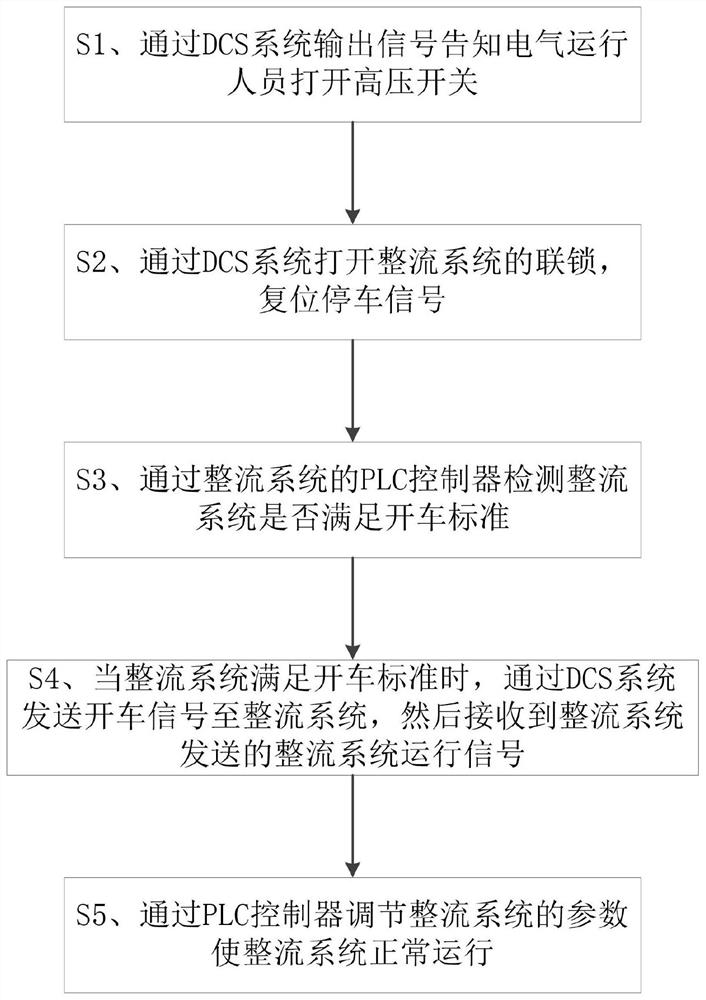

[0053] Such as figure 1 Shown, the present invention a kind of rectifying system start-up control method based on DCS system, comprises steps:

[0054] S1. Inform the electrical operator to turn on the high voltage switch through the output signal of the DCS system;

[0055] S2. Open the interlock of the rectification system through the DCS system, and reset the stop signal;

[0056] S3. Detect whether the rectification system meets the start-up standard through the PLC controller of the rectification system;

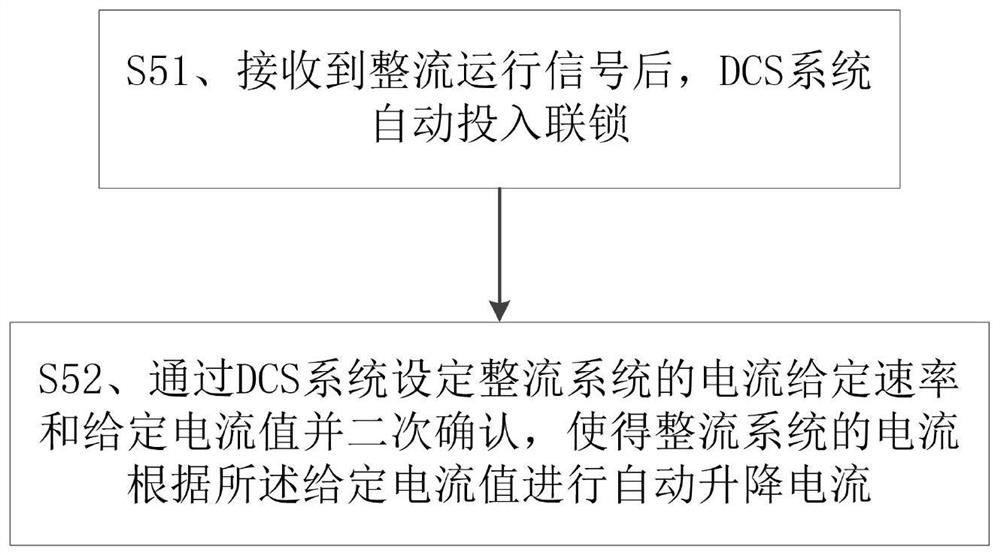

[0057] S4. When the rectification system meets the start-up standard, send a start-up signal to the rectification system through the DCS system, and then receive the rectification system operation signal sent by the rectification system;

[0058] S5. Adjust the parameters of the rectification system through the PLC controller to make the rectification system run normally.

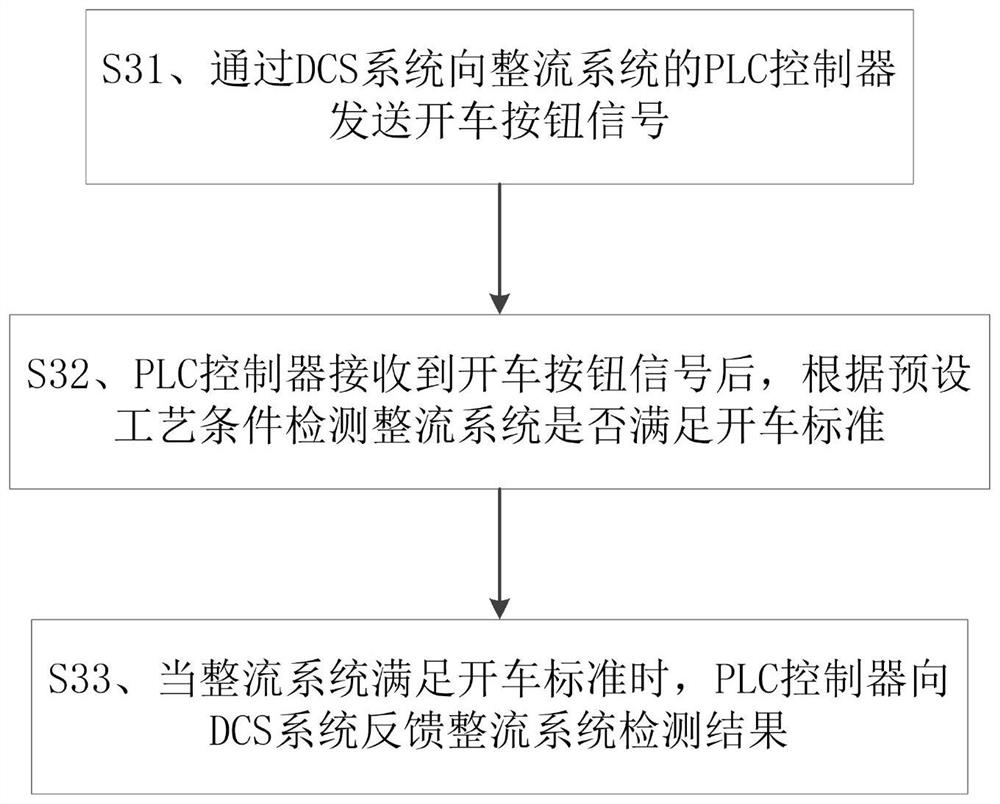

[0059] Further, such as figure 2 As shown, step S3 specifically includes:

[0060] S31. Sen...

Embodiment 2

[0078] Such as Figure 5 Shown, the present invention a kind of rectifying system start-up control system based on DCS system, comprises:

[0079] The output notification module is used to notify the electrical operator to turn on the high voltage switch through the output signal of the DCS system;

[0080] The interlock release module is used to open the interlock of the rectification system through the DCS system and reset the stop signal;

[0081] The start-up standard detection module is used to detect whether the rectification system meets the start-up standard through the PLC controller of the rectification system;

[0082] The operation module is used to send a start-up signal to the rectification system through the DCS system when the rectification system meets the start-up standard, and then receive the rectification system operation signal sent by the rectification system;

[0083] The adjustment module is used to adjust the parameters of the rectification system t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com