A fully automatic pneumatic packaging table

A fully automatic packaging platform technology, applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as low work efficiency and difficult temperature control, and achieve uniform heating, avoid misalignment, and uniform force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

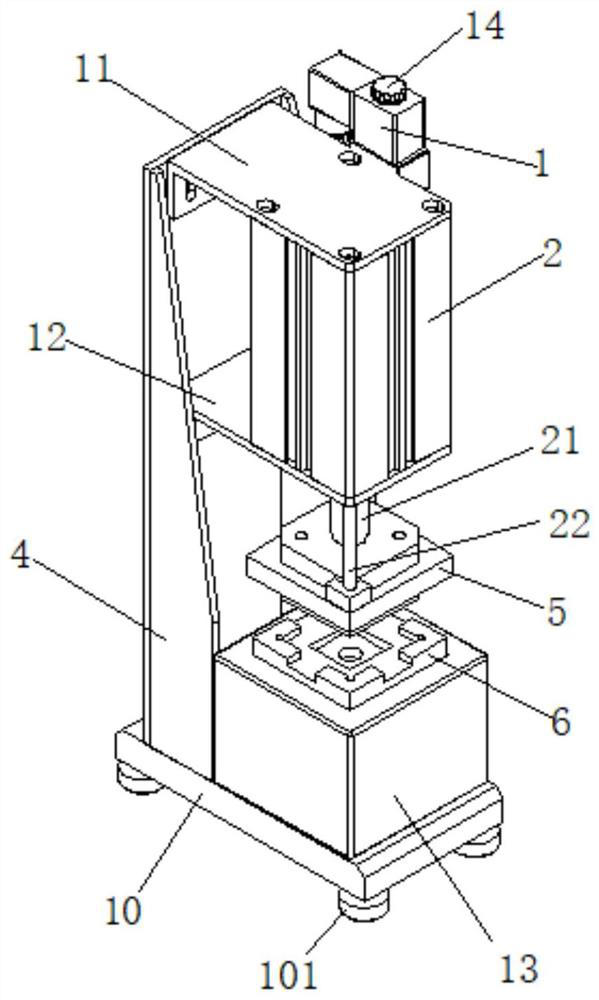

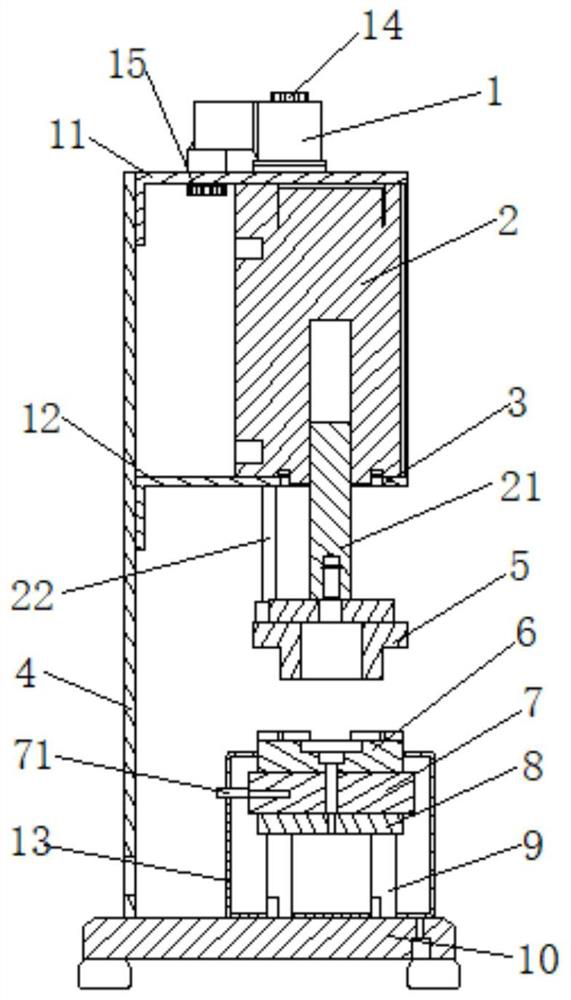

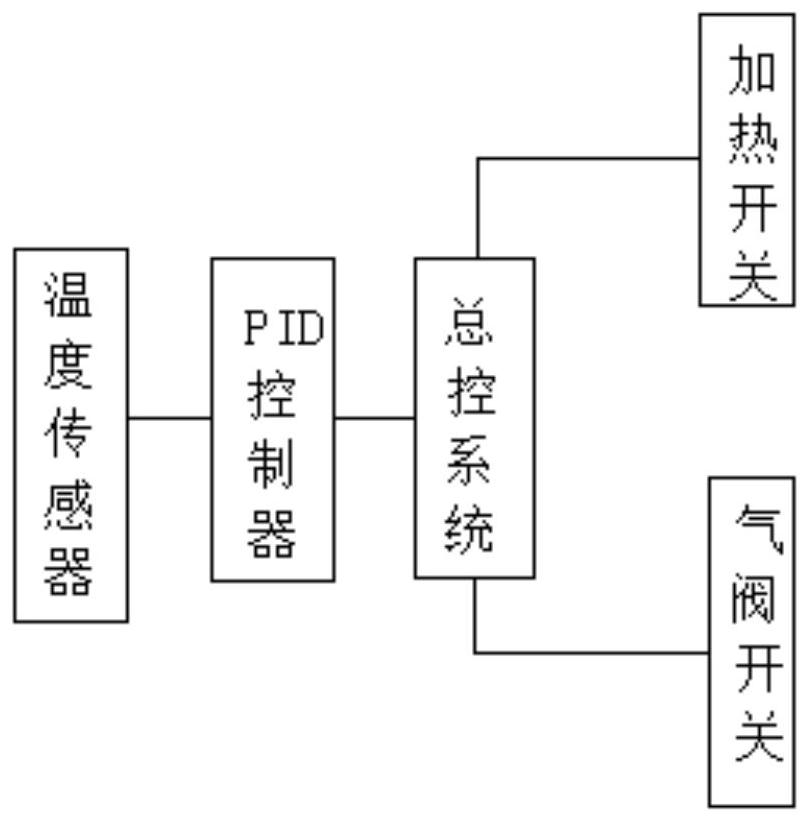

[0021] refer to Figure 1-3 , a fully automatic pneumatic packaging platform, comprising a base 10, the bottom of the base 10 is provided with a number of legs 101, the legs 101 are fixedly connected to the base 10, the number of the legs 101 is four and are respectively located at the four corners of the base 10, the legs 101 Bottoms are provided with buffer pads, which can play a buffering role during work, thereby protecting the legs 101, one side of the top of the base 10 is provided with a side plate 4, the bottom of the side plate 4 is fixedly connected with the base 10, and the side plate 4 The side is provided with reinforcing ribs, so that the side plate 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com