Three servo packaging machine control method

A control method and packaging machine technology, applied in the directions of packaging automatic control, packaging, transportation packaging, etc., can solve the problems that servo drives and servo motors cannot achieve high-speed real-time control, strengthen continuity, etc., achieve fast communication speed and improve control performance , The effect of fast communication speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] As a preferred embodiment of the present invention, this embodiment discloses:

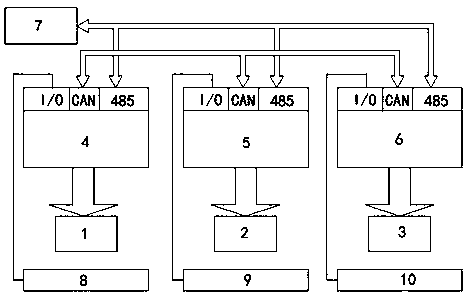

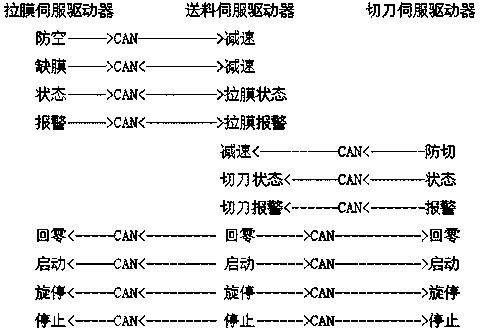

[0036] The three-servo packaging machine control method adopts the built-in PLC feeding servo driver 4, film pulling servo driver 5 and sealing cutter servo driver 6 to respectively drive the feeding motor 1, film pulling motor 2 and sealing cutter motor 3; the feeding servo driver 4 passes The data bus is connected to the film pulling servo driver 5 and the sealing and cutting knife servo driver 6 respectively, and the feeding servo driver 4, the film pulling servo driver 5 and the sealing and cutting knife servo driver 6 realize information interaction through the data bus; It is connected with the information control interface of the feeding servo driver 4, the film pulling servo driver 5 and the sealing and cutting knife servo driver 6; the feeding servo driver 4 is the main control, and the film pulling servo driver 5 and the sealing and cutting knife servo driver 6 are the slave contro...

Embodiment 2

[0047] As another preferred embodiment of the present invention, with reference to the attached figure 1 , this embodiment discloses a control system applicable to the control method of the present invention, specifically as follows:

[0048] Pillow packaging machine control system, including feeding motor 1, film pulling motor 2, sealing and cutting knife motor 3 and three built-in PLC servo drivers, the three built-in servo drivers are feeding servo driver 4, film pulling servo driver 5 and sealing and cutting Knife servo driver 6, these three built-in servo drivers include input and output interfaces, data bus interfaces and signal control interfaces, the data bus interface of the feeding servo driver 4 is connected with the film pulling servo driver 5 and the sealing and cutting knife servo driver 6 respectively through the data bus The data bus interface is connected, and the data interaction between the three is realized. From the control point of view, the feeding servo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com