Motor end cover and motor

A technology of motor end cover and end cover, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of lower pass rate, electromagnetic noise, large stator and rotor, etc., and achieve reduced deformation, reduced stress release, and reduced thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

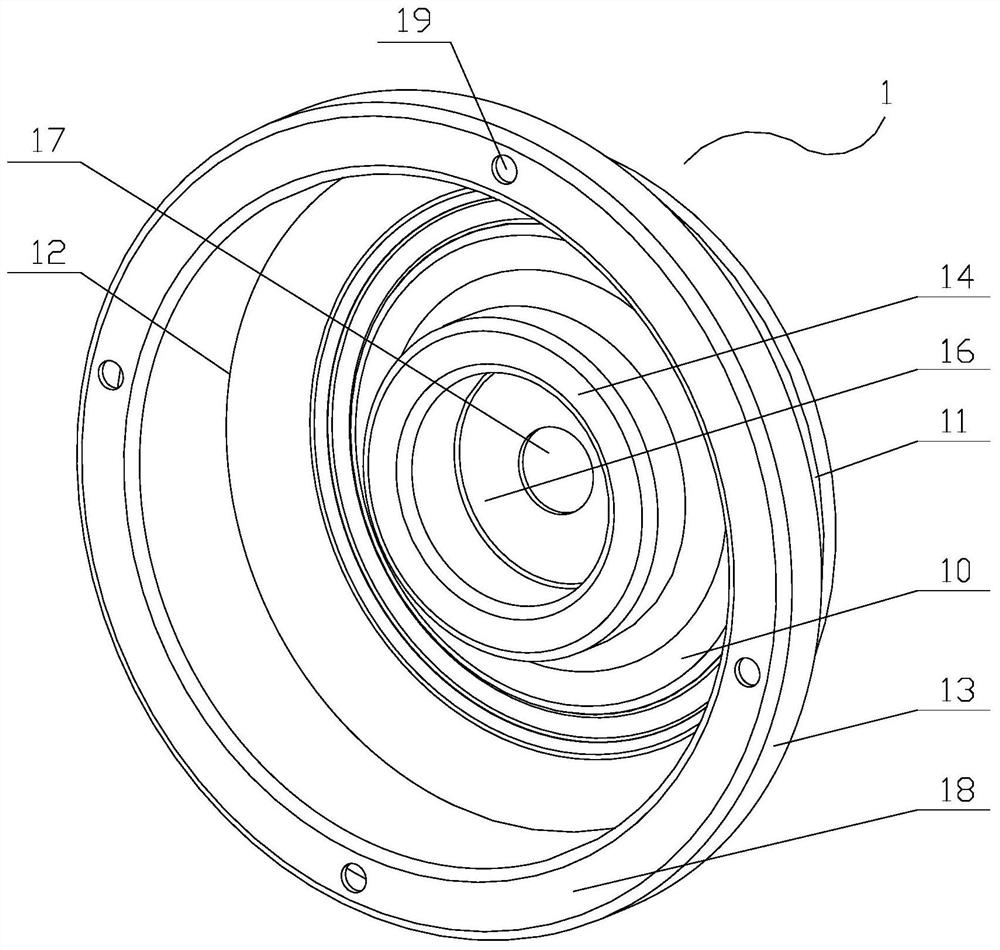

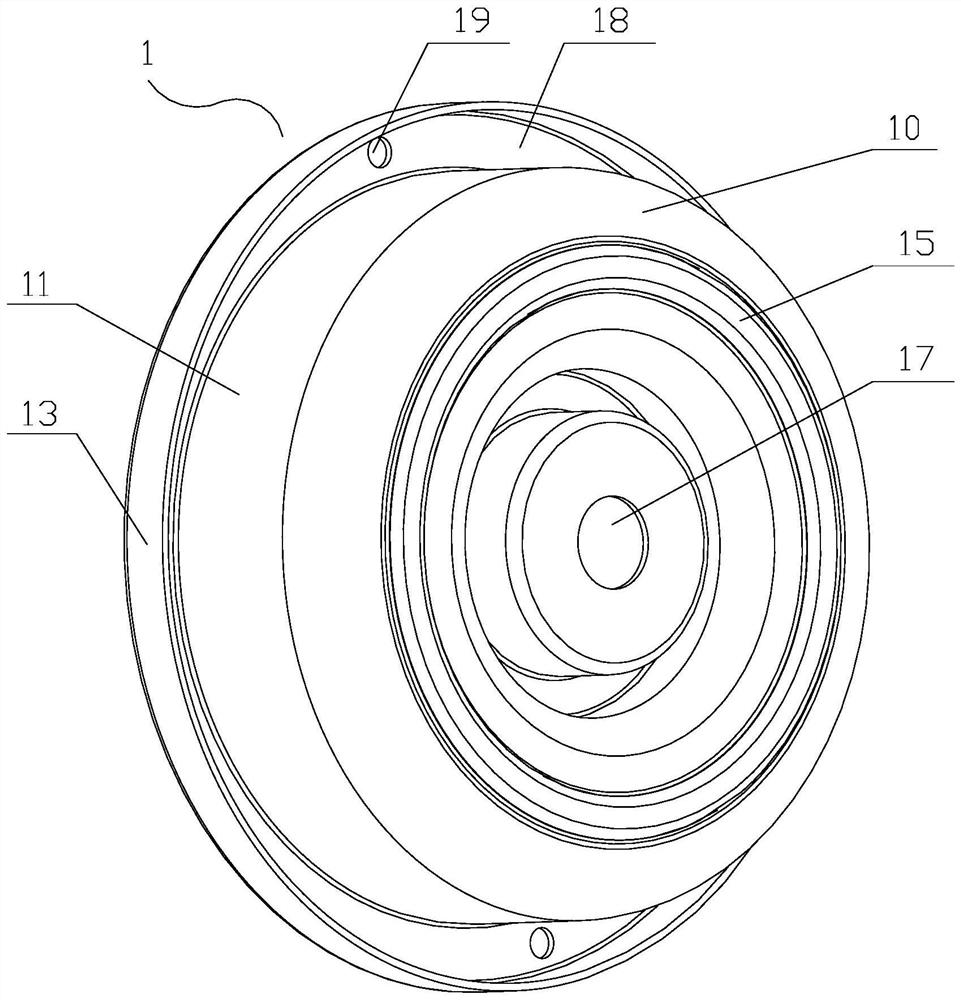

[0032] The present invention will now be further described in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0033] Such as figure 1 and figure 2 As shown, a motor end cover includes an end cover body 1 integrally stretched and formed from a sheet metal. The end cover body 1 includes a cover plate 10 and an outer cylinder 11 extending axially along the edge of the cover plate 10. The cover plate 10 and the outer cylinder The barrel 11 forms an accommodating cavity 12 with one end open, and the end cap body 1 has a reinforced structure, which includes: a first reinforced area, a fold formed by extending the open edge of the accommodating cavity 12 in the radial direction and then folding it in the axial direction. Side 13; the second reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com