A sterile laminar flow chamber for patients with aplastic anemia

An aplastic and anemic technology, applied in treatment rooms, life-saving equipment, separation methods, etc., can solve the problems of reduced system maintenance efficiency, complicated replacement and maintenance operations, and time-consuming replacement of filters, so as to reduce labor load and improve The effect of replacement maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

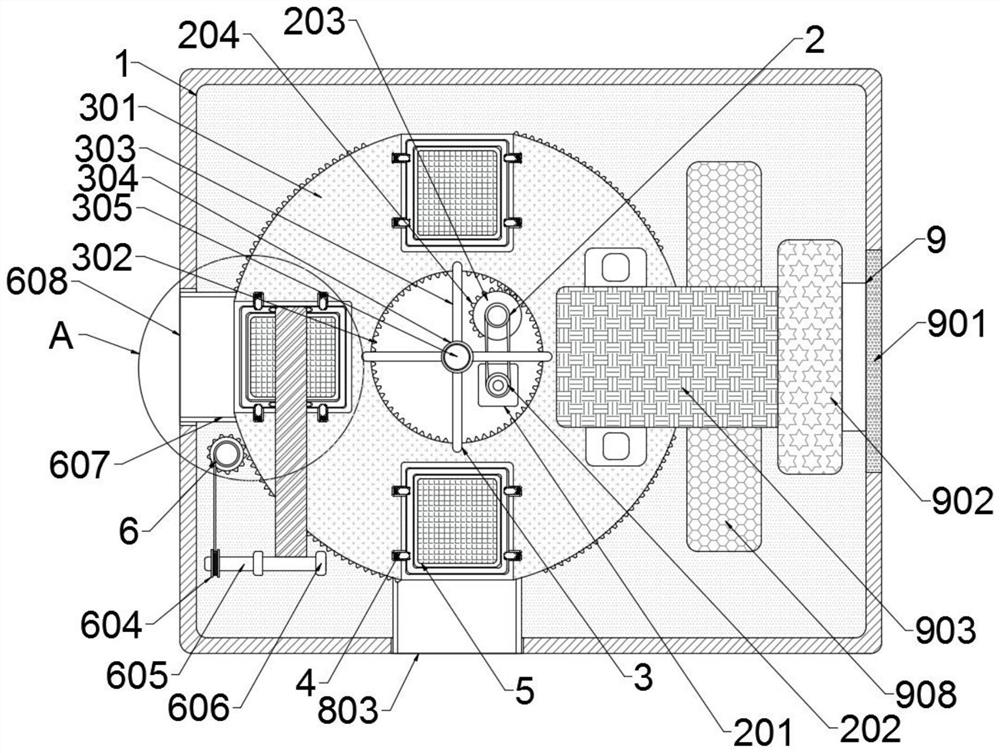

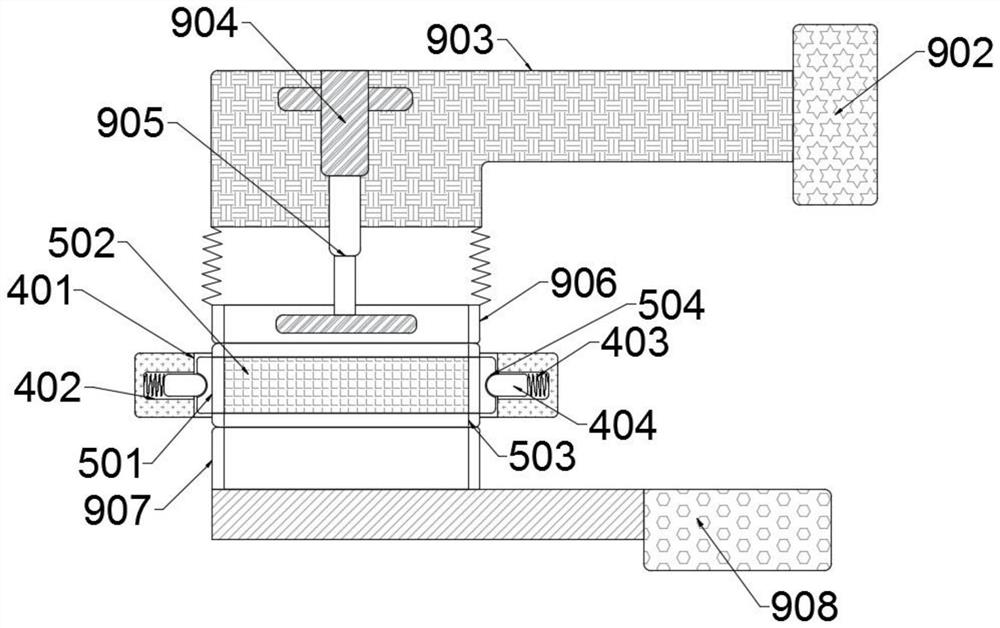

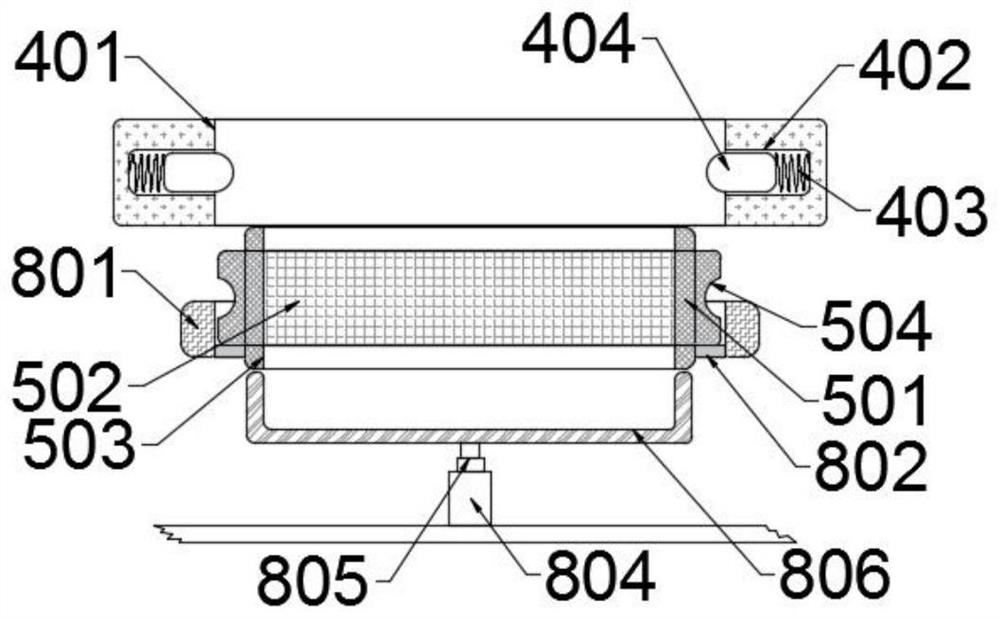

[0028] Example 1: Please refer to figure 1 , 3And 4, a sterile laminar flow chamber for patients with aplastic anemia, including an installation frame 1 installed on the top of the laminar flow chamber, a drive mechanism 2 is installed on the left side of the installation frame 1, and the drive mechanism 2 is connected to the turntable mechanism 3, and the turntable mechanism 3 The installation mechanism 4 is evenly distributed on the top, the filter mechanism 5 is installed on the installation mechanism 4, and the unloading mechanism 6 is installed on the left side of the turntable mechanism 3. The unloading mechanism 6 includes a driven gear 601, and the driven gear 601 is connected with the turntable mechanism 3. , the first winding roller 602 is installed on the driven gear 601, the first winding roller 602 is connected with the second winding roller 604 through the connecting cable 603, the second winding roller 604 is fixedly installed on the rotating rod 605, and the ro...

Embodiment 2

[0033] Example 2: Please refer to Figure 1-4 , a sterile laminar flow chamber for patients with aplastic anemia, comprising an installation frame 1 installed on the top of the laminar flow chamber, a drive mechanism 2 is installed on the left side of the installation frame 1, the drive mechanism 2 is connected to a turntable mechanism 3, and the turntable mechanism 3 is evenly Installing mechanism 4 is distributed, and filtering mechanism 5 is installed on installing mechanism 4, and unloading mechanism 6 is installed on the left side of turntable mechanism 3, and unloading mechanism 6 comprises driven gear 601, and driven gear 601 is connected with turntable mechanism 3 transmission, from The first winding roller 602 is installed on the moving gear 601, the first winding roller 602 is connected to the second winding roller 604 by the connecting cable 603, the second winding roller 604 is fixedly installed on the rotating rod 605, and the rotating rod 605 is installed On the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com