Tailor welding equipment for three-dimensional metallic crystal lattices

A three-dimensional, lattice technology, applied in the field of metal three-dimensional lattice tailor welding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions are further described below with reference to the accompanying drawings and specific embodiments to help understand the content of the present invention.

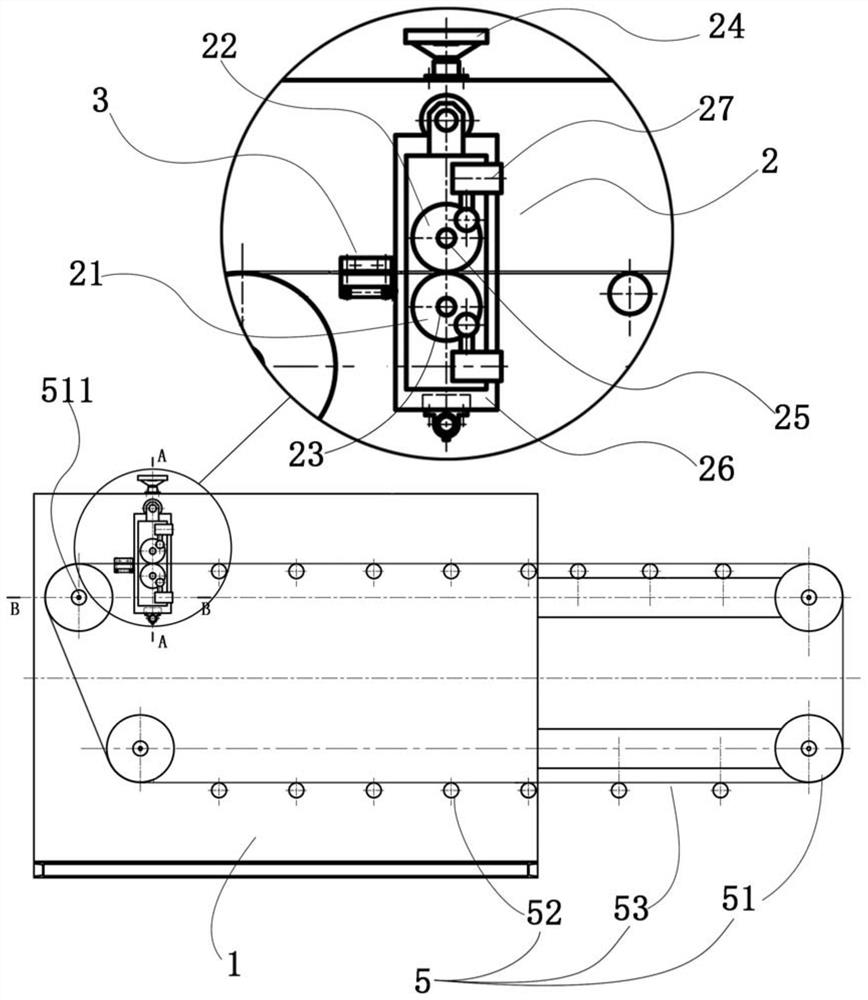

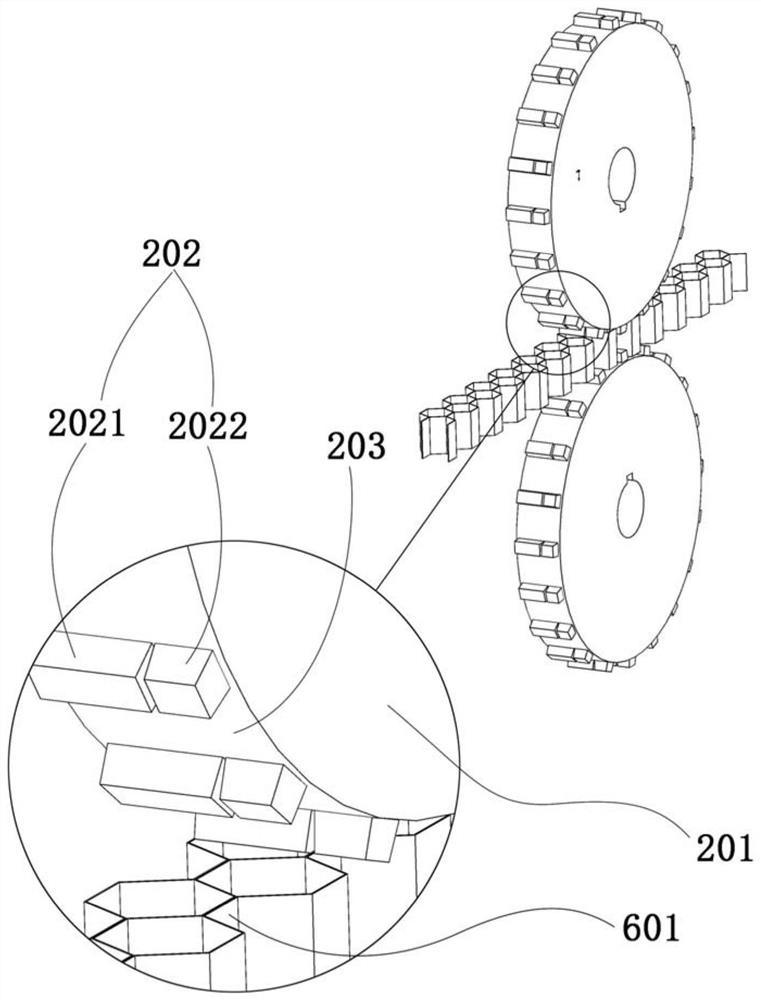

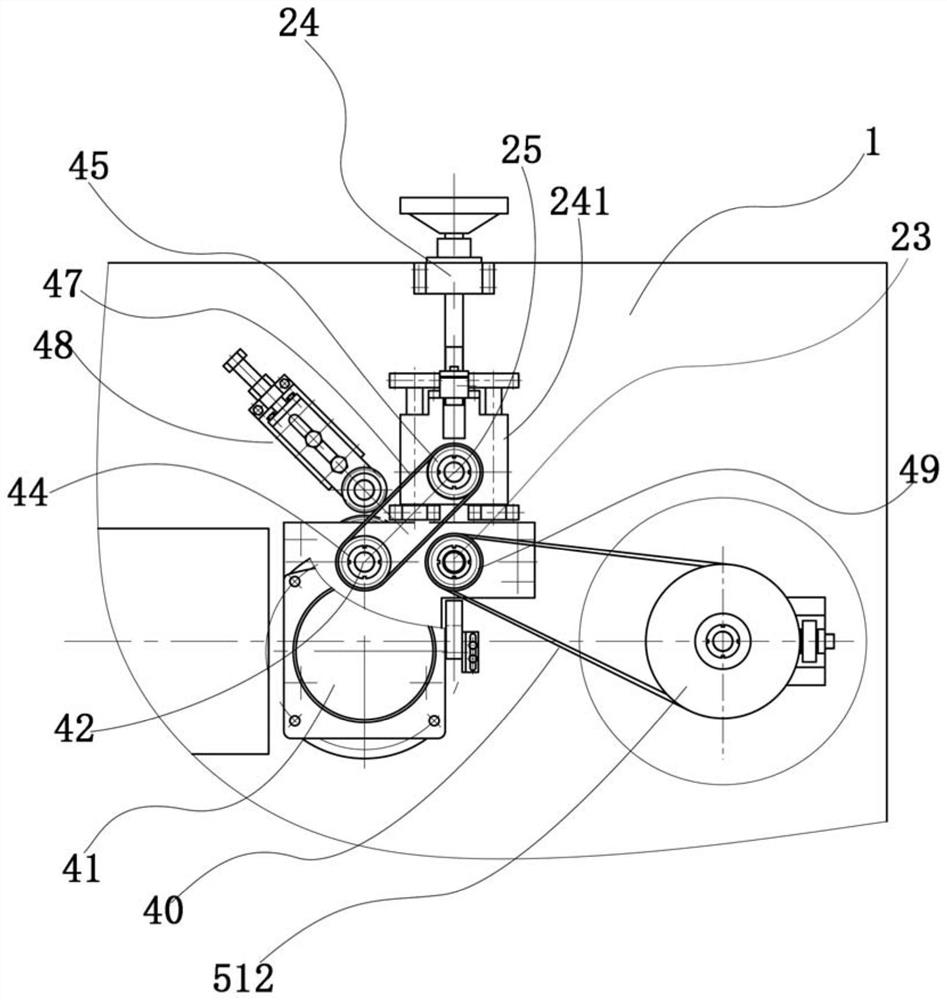

[0034] like figure 1 As shown, the present invention proposes a metal three-dimensional lattice tailor-welding equipment for continuously positioning and welding metal corrugated strips to form a metal three-dimensional lattice, which includes a frame 1 for fixing other components, a welding device 2, a feeding material guide 3 and drive unit 4 (see image 3 ).

[0035] The welding device 2 , the feeding guide rail 3 and the driving device 4 are all fixed to the frame 1 .

[0036] The metal three-dimensional lattice tailor-welding equipment also includes a guide wheel group 5 for feeding.

[0037] The guide roller group 5 includes a plurality of idler guide rollers 52 in a horizontal position and corner rollers 51 at four corners. The metal corrugated belt is annularly overlapped and conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com