Modified biochar algistat as well as use method and preparation method thereof

A technology of biochar and algae inhibitor, which is applied in the field of water pollution treatment, to achieve the effect of fast adsorption, easy to obtain and cheap source, and save the time of algae inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of modified biochar algae inhibitor, the specific steps are as follows:

[0032] The dried rice straw was crushed and passed through a 200-mesh sieve, and then 1.0 g of biomass raw material under the sieve was added to 100 ml of 2.5 g / L magnesium chloride, stirred for 24 hours, evaporated and crystallized. Four parts of biomass after appropriate crystallization were taken and placed in four crucibles respectively. Wrap the crucible containing the biomass with tin foil, and place it in a nitrogen-filled box-type atmosphere furnace for anaerobic carbonization; set the target temperatures of the four crucibles at 400°C, 500°C, 600°C, and 700°C, respectively, and set the temperature at 5°C / Heating at a heating rate of min to the target temperature, continued carbonization at the target temperature for 2 h, and naturally cooled to room temperature to obtain four different magnesia-based biochars, which were sealed and stored for future use, respectively...

Embodiment 2

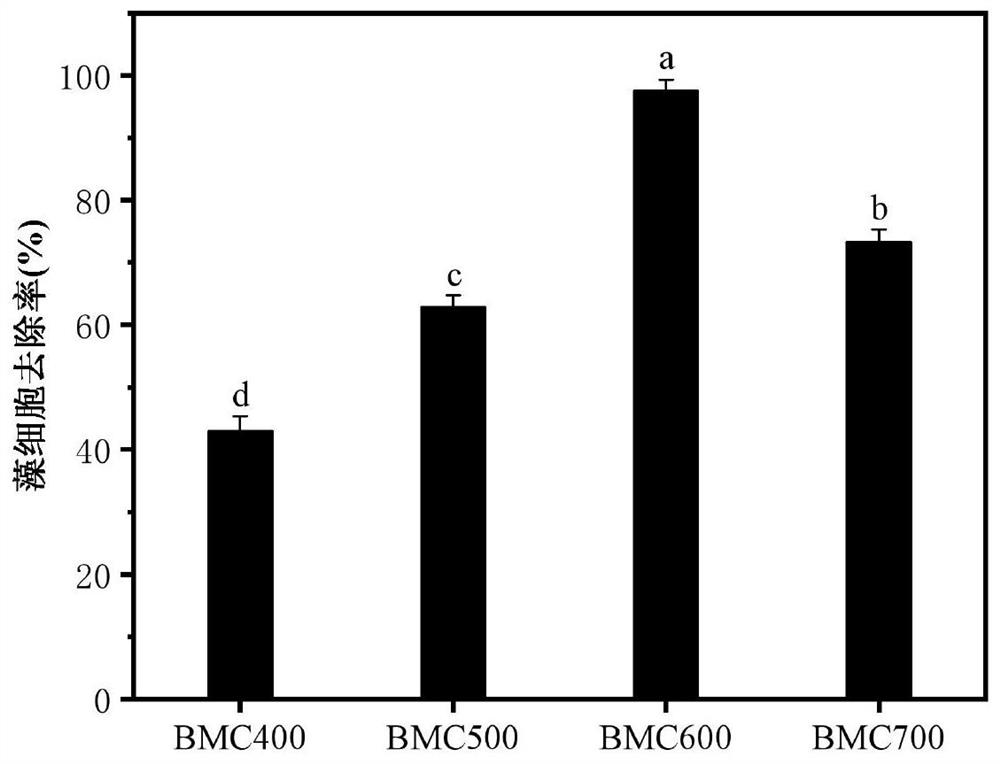

[0036] The modified biochar algae inhibitors prepared at different carbonization temperatures carry out the algae inhibition method, and the specific process is as follows:

[0037] Step 1: Take the microcystis aeruginosa algae liquid grown to the logarithmic phase cultured by BG11 without any pretreatment.

[0038] Step 2. Add four parts of 0.4 g of modified biochar algicides prepared at different calcination temperatures (i.e. BMC400, BMC500, BMC600 and BMC700) to four parts of 100 mL of algae suspension, and the magnetic stirring speed is set to 100 rpm. After reacting for 5 minutes, place a strong magnet at the bottom of the reactor and let it stand for 10 minutes.

[0039] Step 3: Take four samples of the supernatant of the algal suspension, measure the concentration of chlorophyll a, and determine the removal rate T of the microcystis aeruginosa cells by the modified biochar algicides prepared at four different carbonization temperatures.

[0040] The cell removal rate ...

Embodiment 3

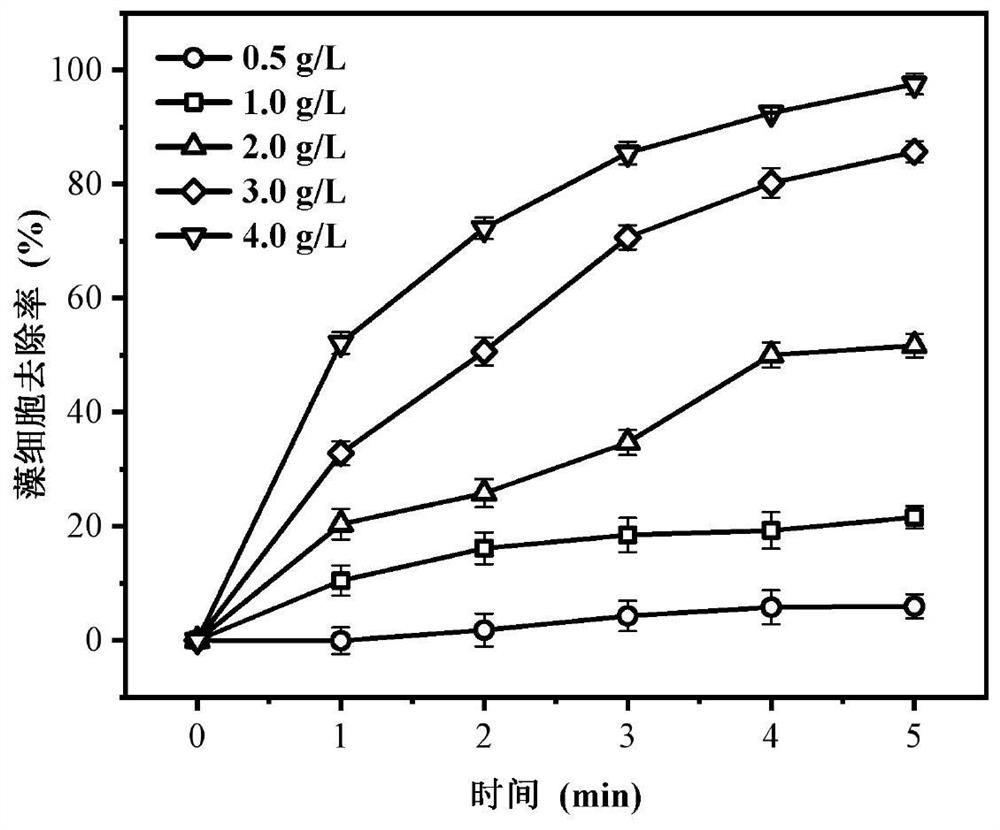

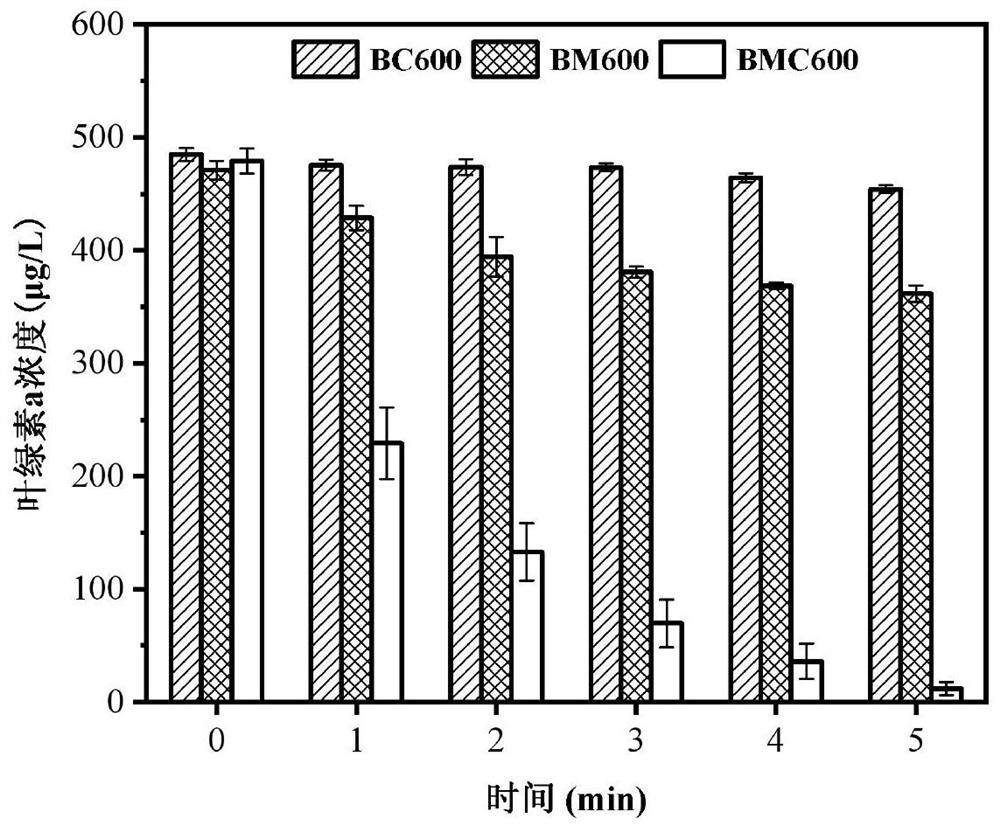

[0045] The comparison of algae inhibitory effect of BMC600 modified biochar algae inhibitor under different dosage and different treatment time is as follows:

[0046] Step 1: Take the microcystis aeruginosa algae liquid grown to the logarithmic phase cultured by BG11 without any pretreatment.

[0047]Step 2: Using BMC600 modified biochar to conduct four sets of algae inhibition tests on the suspension of Microcystis aeruginosa. In each group of algae inhibition tests, the amount of algae suspension was 100ml, and the magnetic stirring speed was set at 100rpm. The dosages of BMC600 modified biochar in the four groups of algae inhibition tests were 0.5, 1.0, 2.0, 3.0, 4.0 g / L respectively. For each group of algae inhibition tests, samples were taken at 0, 1, 2, 3, 4, and 5 minutes after the catalyst was added, and the chlorophyll a concentration of the samples was measured, and the removal rate T of Microcystis aeruginosa cells was calculated respectively.

[0048] The relati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap