Post-acid-supplementing dyeing method and textile dyed by same

A dyeing method and technology for textiles, applied in the field of textile dyeing and finishing, can solve the problems of reducing the dyeing speed of dyes, and the dyeing will be white.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The post-acid dyeing of the full nylon lace lace of embodiment 1 band strand

[0071] The present embodiment provides a kind of post-acid dyeing method, and it comprises the following steps:

[0072] (1) Put the textile to be dyed (full nylon lace lace fabric with strands) into the dyeing device;

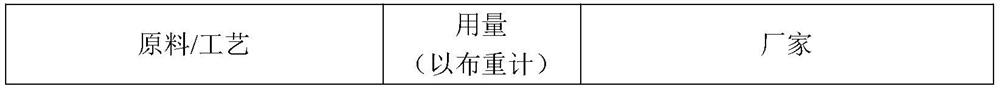

[0073] (2) At 38°C, add acidic leveling agent TBW-95, and add the prepared dye at a speed of 20L / min;

[0074] (3) Start at 38°C, heat up to 98°C at a rate of 1.2°C / min, and keep warm for 20 minutes;

[0075] (4) After the heat preservation is completed, cool down to 38°C at a speed of 3.0°C / min, and then add glacial acetic acid solution C03 at a speed of 20L / min;

[0076] (5) After adding the glacial acetic acid solution, raise the temperature to 98°C at a rate of 1.2°C / min, and keep it warm for 20 minutes;

[0077] (6) After the heat preservation is over, cool down to 80°C at a speed of 3.0°C / min. After the dyeing is completed, the dyed textile (full nylon lace fabric wi...

experiment example

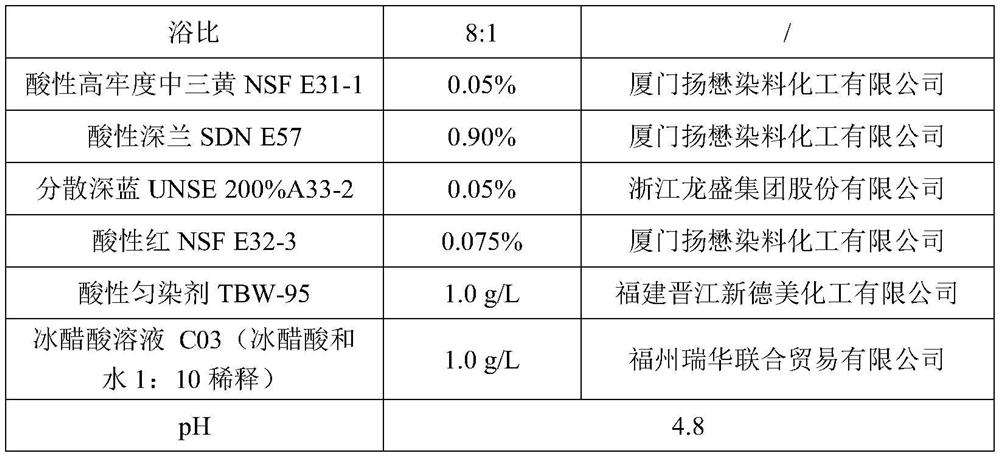

[0105] EXPERIMENTAL EXAMPLE Investigation on the dyeing effect of strands of textiles after dyeing

[0106] In this example, the dyed textiles in Example 1 and Comparative Examples 1-4 were cut and color-matched to evaluate the dyeing effect of strands. The dyeing effects of the strands of Example 1 and Comparative Examples 1 to 4 are shown in Table 2, and the comparison results are the average level of the dyeing effects of three different batches of cut samples of dyed fabrics after color matching.

[0107]The strand dyeing effect table of table 2 embodiment 1 and comparative examples 1~4

[0108]

[0109]

[0110] From the dyeing effect of Table 2, it can be known that the dyeing method of the present invention can make the internal fibers of the strands absorb enough dyestuff, which is consistent with the color of the external fibers of the strands. After the fabric is stentered, the cloth surface will not The phenomenon of white spots appears, which effectively sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com