A batik process of vegetable tanned leather with cracks

A technology of vegetable tanned leather and batik, applied in the field of leather dyeing, can solve problems such as poor clarity of cracked texture, unsatisfactory modern people, monotony, etc., achieve good dyeing effect, increase use value, and facilitate diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

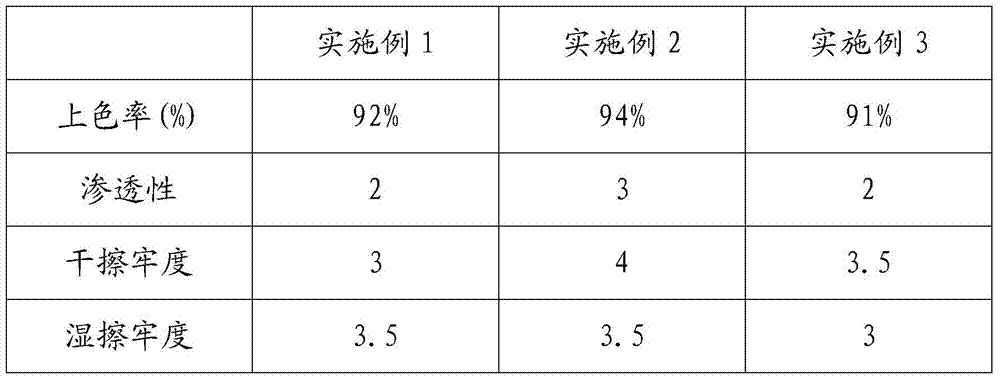

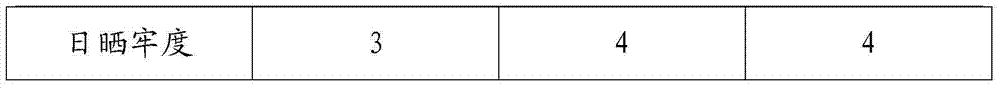

Embodiment 1

[0030] A vegetable tanned leather batik process with cracks is carried out according to the following steps: select suitable vegetable tanned leather; place the vegetable tanned leather flat, moisten the leather surface with clear water, and control the moisture content at 23%; The dyeing agent is evenly dyed on the vegetable tanned leather, and the moisture content is controlled at 40% to make the base color vegetable tanned leather; wax blowing, firstly make the base color vegetable tanned leather into a curled state; then melt the wax into a wax liquid, and put the wax The liquid is covered on the vegetable tanned leather where the cracked texture is required, and the temperature of the wax liquid is controlled at 72°C; to make the waxy texture, in the waxed part of the vegetable tanned leather, according to the grain direction and grain density of the desired cracked texture at the same time, ensure that the wax and the vegetable tanned leather are not separated during the ...

Embodiment 2

[0032] A kind of batik process of vegetable tanned leather with tortoise cracks, according to the following steps: select suitable vegetable tanned leather; carry out acid treatment to vegetable tanned leather with formic acid, control the water content at 25%; dye the first dyeing agent evenly On the vegetable tanned leather, control the moisture content at 50% to make the base color vegetable tanned leather; blow wax, first make the base color vegetable tanned leather into a curly state; then melt the wax into wax liquid, and cover the wax liquid on the vegetable tanned leather Where the cracked texture is needed on the leather, control the temperature of the wax solution at 70°C; to make the waxed texture, on the part of the vegetable tanned leather covered with wax, flatten it by hand according to the grain direction and grain density of the desired cracked texture At the same time, ensure that the wax and the vegetable tanned leather are not separated during the kneading p...

Embodiment 3

[0034] A vegetable tanned leather batik process with cracks is carried out according to the following steps: select suitable vegetable tanned leather; place the vegetable tanned leather flat, moisten the leather surface with clear water, and control the moisture content at 30%; The dyeing agent is evenly dyed on the vegetable tanned leather, and the moisture content is controlled at 60% to make the base color vegetable tanned leather; wax blowing, firstly make the base color vegetable tanned leather into a curled state; then melt the wax into a wax liquid, and put the wax Cover the place where the cracked texture is needed on the vegetable tanned leather, and control the temperature of the wax liquid at 75°C; to make the waxy texture, in the waxed part of the vegetable tanned leather, according to the grain direction and grain density of the required cracked texture at the same time, ensure that the wax and the vegetable tanned leather are not separated during the kneading proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com