An ultra-short two-way fully hydraulic while-drilling jar

A full-hydraulic, jar technology, applied in the field of machinery, can solve the problems of easy wear of conical valves, impact on jarring performance, complex structure, etc., to achieve the effects of convenient processing, lower processing costs, and meet strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

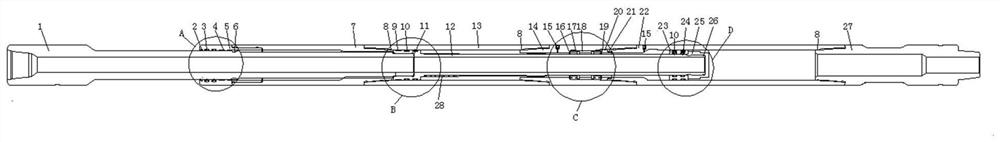

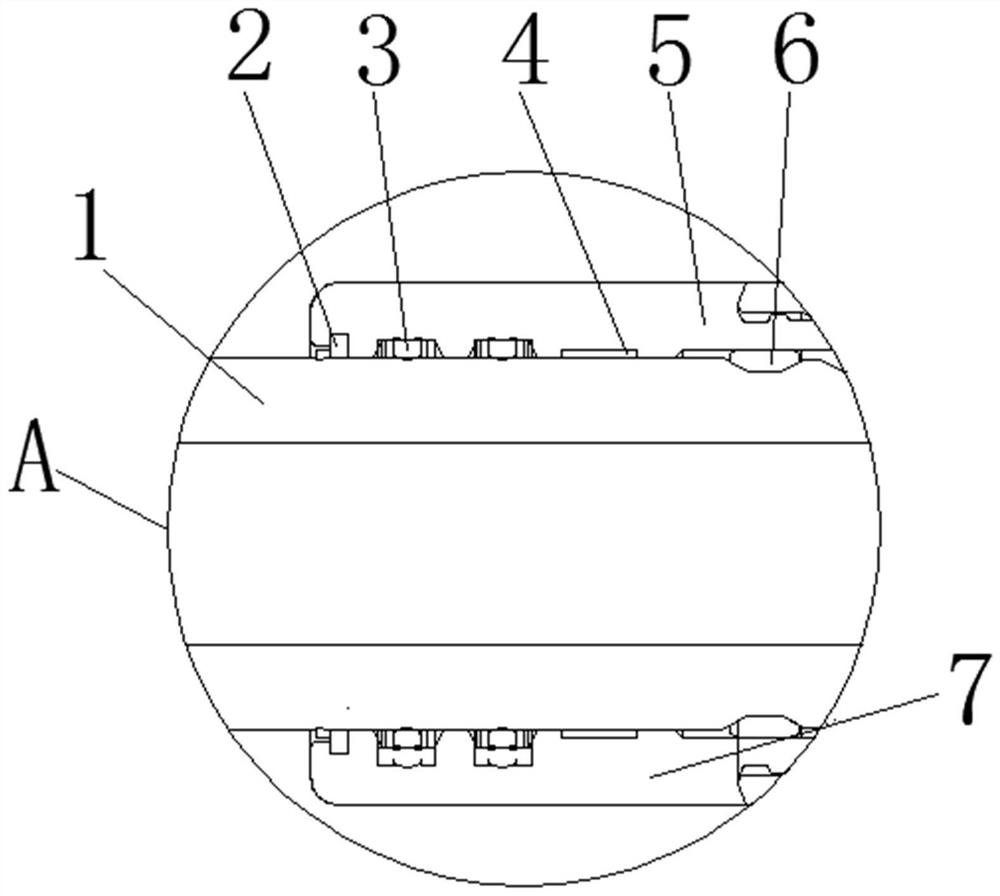

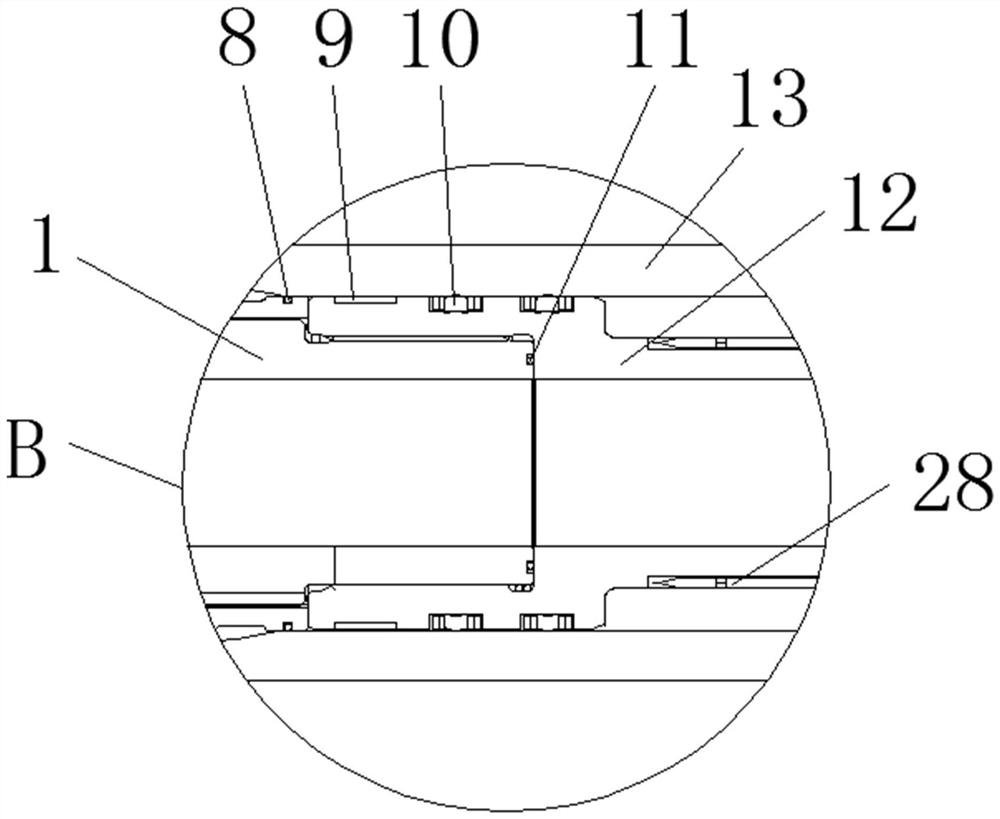

[0047]An ultra-short two-way fully hydraulic while-drilling jar, comprising a transmission shaft 1, a first combined sealing ring 3 and a third O-ring 20, the right outer end of the transmission shaft 1 is fixedly connected with a spline joint 7, so The outside of the right end of the spline joint 7 is fixedly connected with a shock cylinder 13, the left end of the spline joint 7 is fixedly connected with a transmission shaft joint 5, and the right inner end of the transmission shaft joint 5 is fixedly connected with an anti-drop half ring 6. A transmission shaft 1 is fixedly connected to the inner side of the anti-drop half ring 6, and a first centralizing copper ring 4 is fixedly connected to the internal side of the transmission shaft joint 5 at the left end position of the anti-falling semi-ring 6, and the inner side of the first centralizing copper ring 4 A transmission shaft 1 is fixedly connected, the right end of the transmission shaft 1 is fixedly connected with a shoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com