Radiation enhanced LED (light-emitting diode) circuit board and manufacturing method and application thereof

A technology of LED circuit board and LED base, which is applied in printed circuit manufacturing, printed circuit, lighting and heating equipment, etc., can solve the problems of unreasonable position design of heat dissipation fins and poor heat dissipation effect, so as to improve heat dissipation effect and heat dissipation. Good effect, the effect of simplifying the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

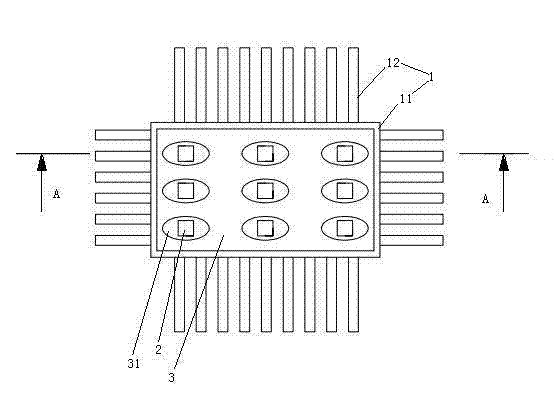

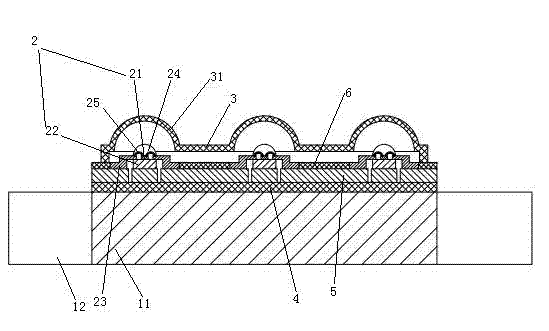

[0045] Embodiment one, see figure 1 , an LED circuit board with enhanced heat dissipation, comprising a heat dissipation main body 1 and a plurality of LED illuminants 2 .

[0046] The heat dissipation main body 1 is made of aluminum alloy.

[0047] The heat dissipation body 1 includes a base 11 and a plurality of heat dissipation fins 12 . The base body 11 is a quadrilateral plate structure. The heat dissipation fins 12 are distributed on the front, rear, left, and right sides of the base body 11 . The base body 11 and the cooling fins 12 are integrally structured.

[0048] The LED illuminants 2 are arranged on the underside of the base body.

[0049] A light-transmitting plate 3 is provided on the underside of the base body 11 . A plurality of downwardly protruding cups 31 are provided on the light-transmitting plate 3 .

[0050] The cup body 31 is integrated with the light-transmitting plate 3 . The quantity of the cup body 31 is equal to the quantity of the LED illu...

Embodiment 2

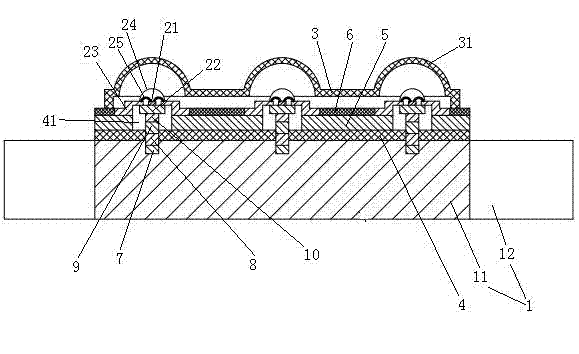

[0063] Embodiment two, see image 3 , the difference with Embodiment 1 is:

[0064] The heat dissipation main body 1 is made of aluminum.

[0065] Via holes 41 are provided on the insulating layer 4 . The through hole 41 cuts the conductive line 5 into two parts located on both sides of the through hole 41 . The through hole 41 protrudes into the interior of the base body 11 .

[0066] A zinc layer 7 , a nickel layer 8 , a copper layer 9 and a tin layer 10 are sequentially provided on the substrate 41 corresponding to the through hole 41 .

[0067] The LED base 22 is penetrated in the through hole 41 and soldered on the tin layer 10 .

[0068] The LED base 22 , the zinc layer 7 , the nickel layer 8 , the copper layer 9 and the tin layer 10 are separated from the conductive circuit 5 .

[0069] The two lead-out pins 23 of the LED illuminant 2 are connected to the two parts of the conductive circuit 5 located on both sides of the through hole 41 .

[0070] The manufacturin...

Embodiment 3

[0082] Embodiment three, see Figure 4 , The difference with the first embodiment is: the upper side of the base body 11 is provided with cooling ribs 13 . Of course, on the basis of the second embodiment, the heat dissipation ribs 13 can also be provided on the upper side of the base body 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com