Stator punching sheet structure of low-noise oil-cooled flat wire motor

A stator punching, low-noise technology, applied in the shape/pattern/structure of winding insulation, magnetic circuit shape/pattern/structure, electromechanical device, etc., can solve the problem of affecting the magnetic field flow, such as motor torque output, and achieve heat dissipation. , the effect of improving utilization and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

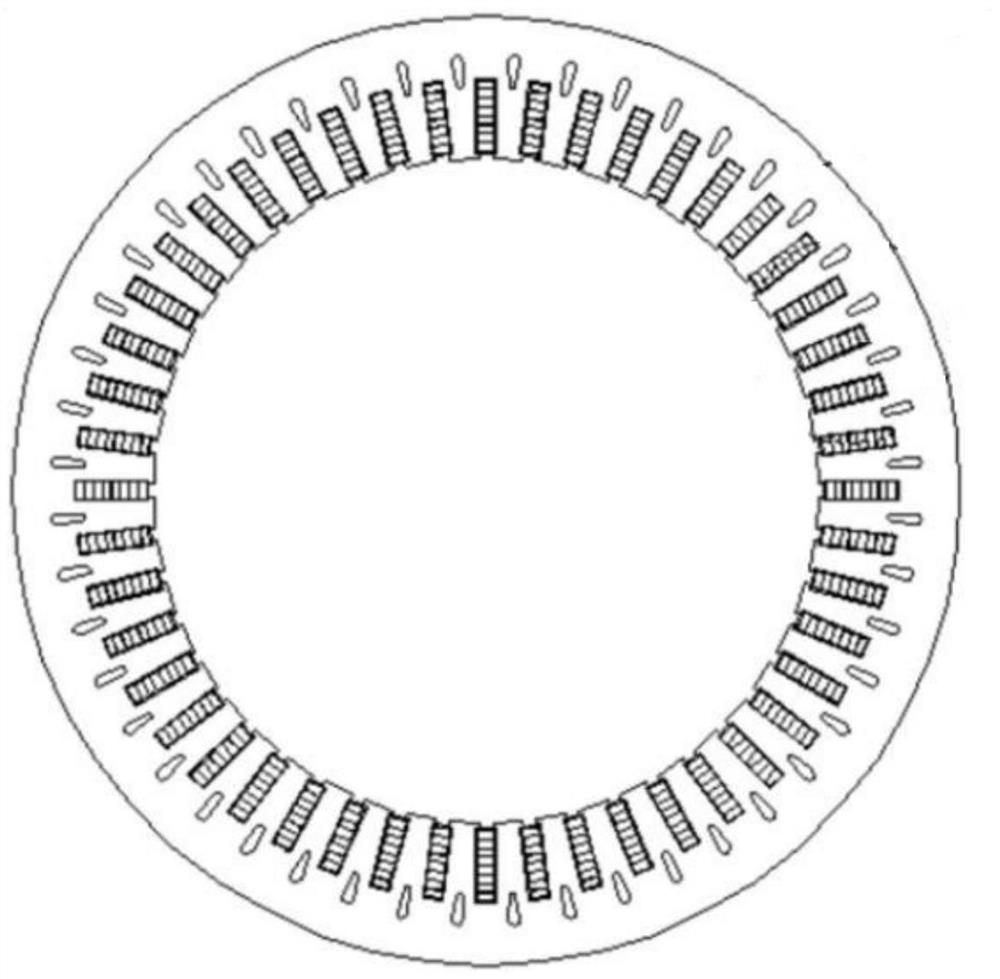

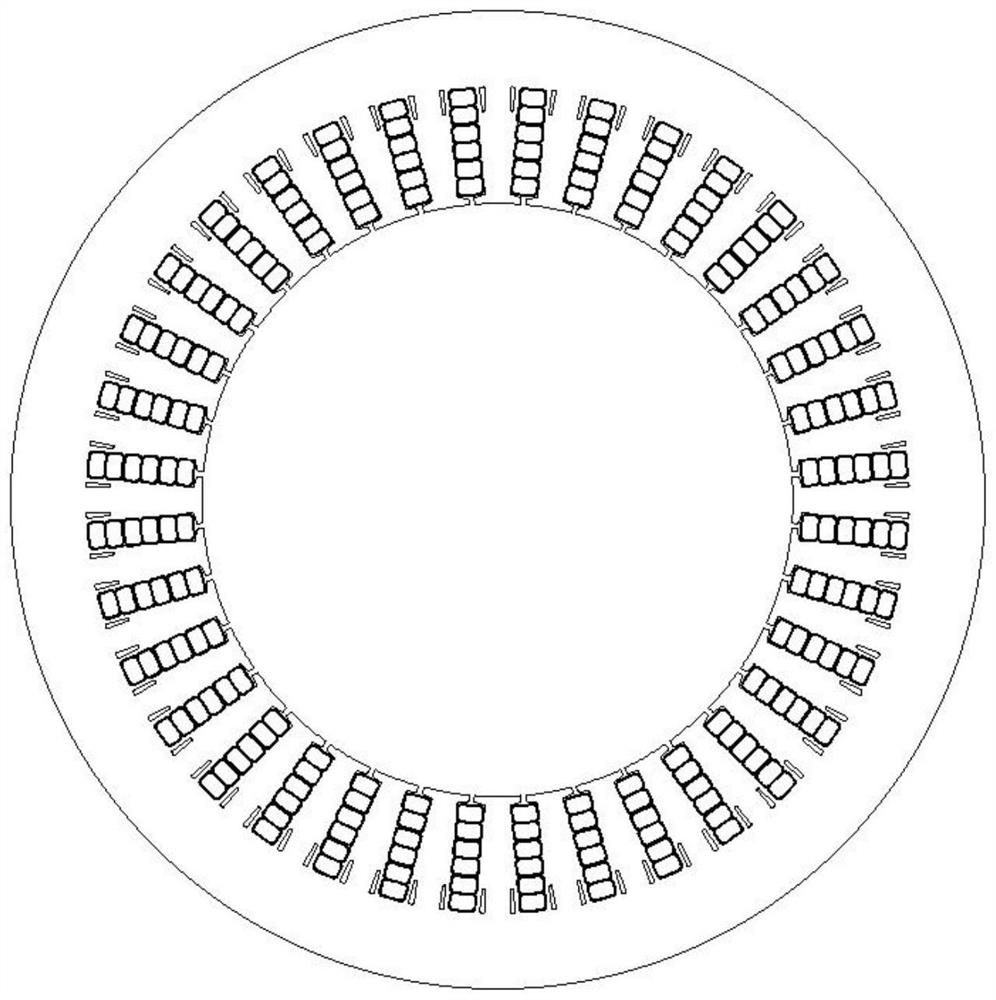

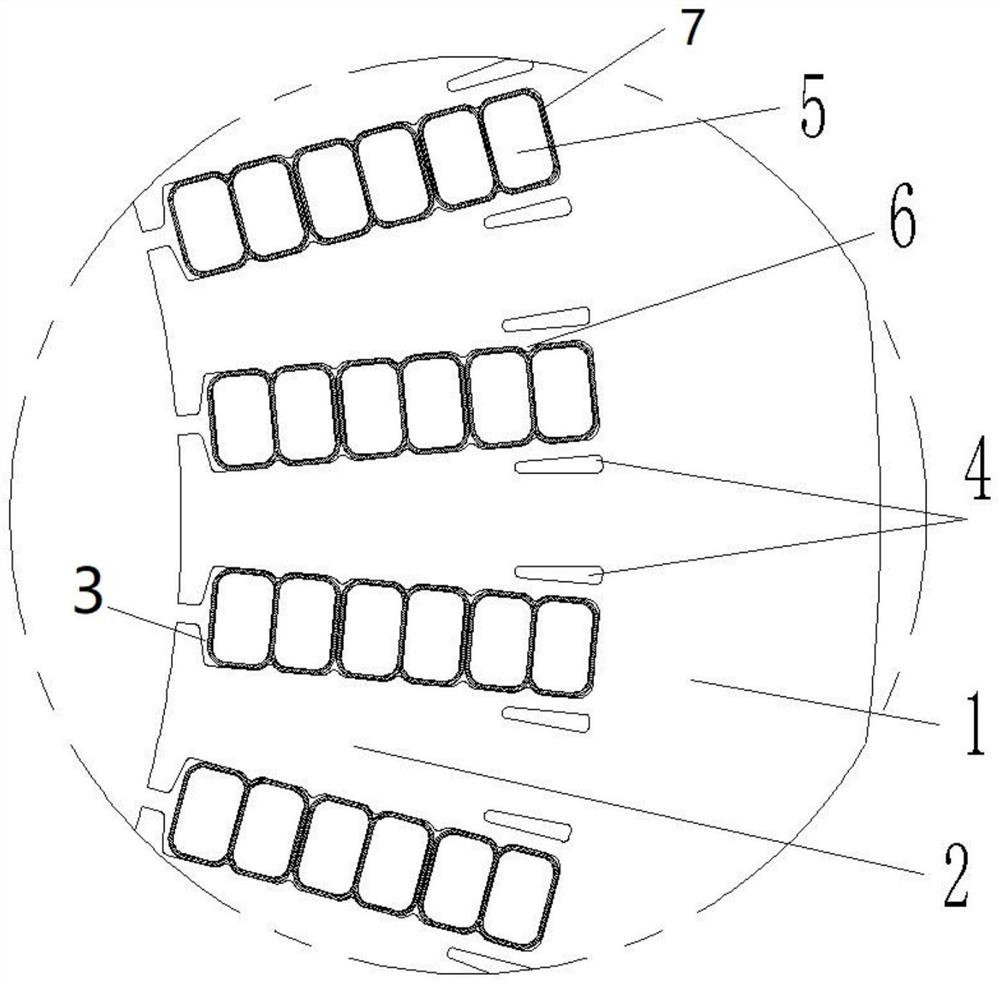

[0026] refer to Figure 1 ~ Figure 2 As shown, the stator punching structure of a low-noise oil-cooled flat wire motor provided by the present invention includes a stator punching body 1, and several stator teeth 2 are arranged at equal intervals in the circumferential direction of the stator punching body. A stator slot 3 is provided between the two stator teeth. A pair of oil through holes 4 are arranged on each stator tooth, and the oil through holes are arranged symmetrically with respect to the central line A of the stator teeth. In this embodiment, by changing the arrangement of the oil holes, the oil holes are not located on the center line of the stator teeth, so that the oil holes will not affect the circulation of the magnetic field and the torque output of the motor.

[0027] According to the above technical solution, the oil passage hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com