Double-wind-wheel wind turbine generator with cabin of auxiliary supporting structure

A support structure and auxiliary support technology, applied in the installation/support of wind turbine configuration, wind power generation, machines/engines, etc., can solve the problems of increasing the cost of the support structure of wind turbines, increasing the size of the nacelle, and structural instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

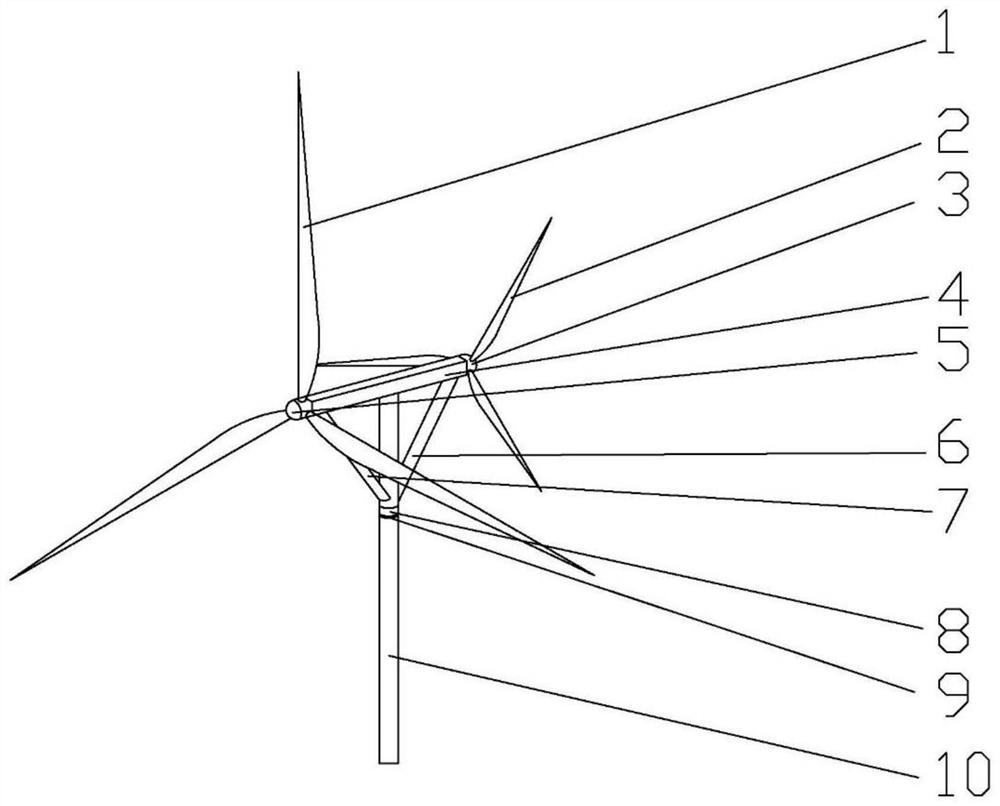

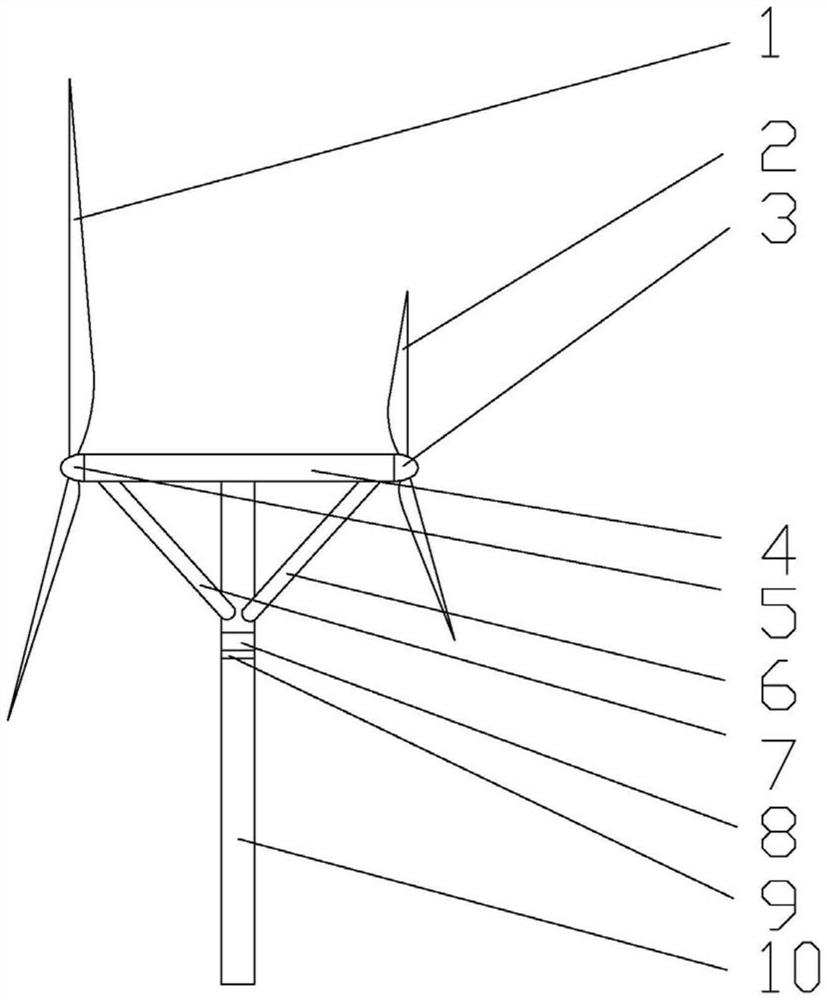

[0031] like figure 1 and figure 2 As shown, a double-wind-wheel wind turbine with an auxiliary support structure for the nacelle of the present invention includes a front wind rotor 1, a rear wind rotor 2, a rear hub 3, a nacelle 4, a front hub 5, a rear nacelle support structure 6, Front nacelle support structure 7, yaw system 8, tower tube flange 9, tower tube 10. The number of blades of the front wind rotor is 1 to 4, and the number of rear wind rotors is 1 to 4, which are evenly distributed on the circumferential plane. In this embodiment, preferably, the front wind wheel 1 and the rear wind wheel 2 each have 3 blades.

[0032] The diameter of the front wind wheel ranges from 20 to 300 meters, and the diameter of the front wind wheel is 0.1 to 10 times the diameter of the rear wind wheel. In this embodiment, the diameter of the front wind wheel 1 is preferably 150 meters, and the diameter of the rear wind wheel 2 is 80 meters. The front wind wheel 1 and the front whee...

Embodiment 2

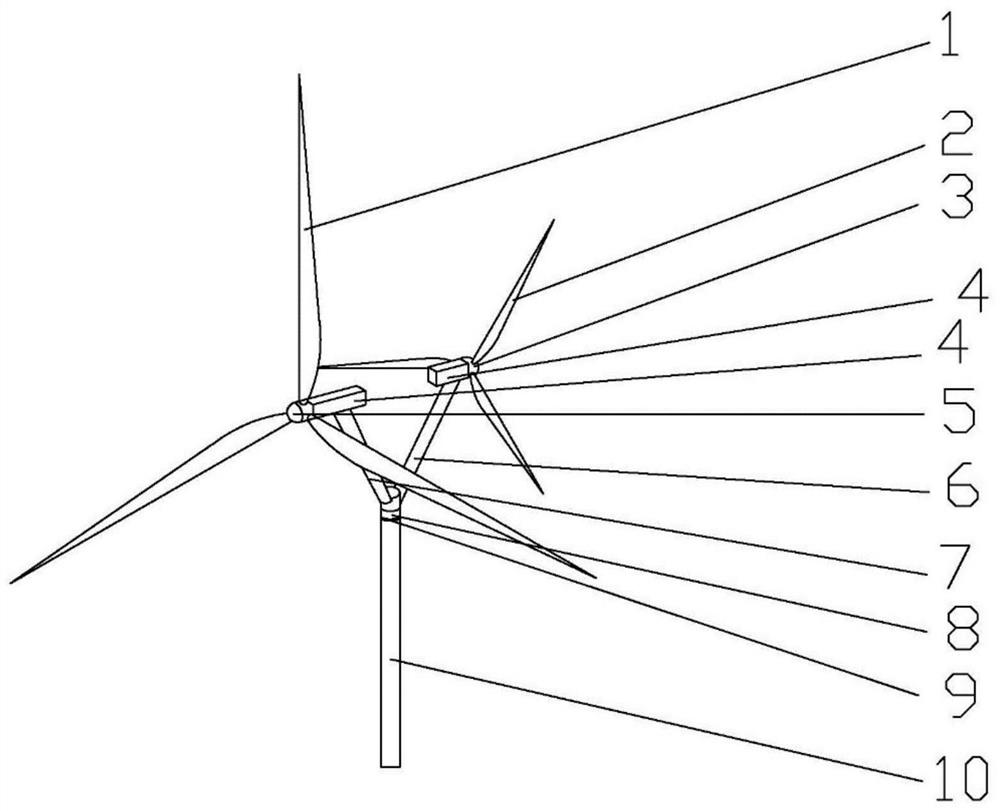

[0040] like image 3 and Figure 4 As shown, a double wind turbine wind turbine with nacelle auxiliary support structure of the present invention includes a front wind rotor 1, a rear wind rotor 2, a rear hub 3, a nacelle 4, a front hub 5, a rear nacelle support structure 6, a front Nacelle support structure 7, yaw system 8, tower tube flange 9, tower tube 10. The front wind wheel 1 and the rear wind wheel 2 each have 3 blades. The front wind wheel 1 has a diameter of 150 meters, and the rear wind wheel 2 has a diameter of 80 meters. The front wind wheel 1 and the front wheel hub 5, the rear wind wheel 2 and the rear wheel hub 3 are connected by flanges. The cabin 4 is a segmented cabin; the segmented cabin is divided into a front cabin and a rear cabin, the front cabin is connected to the front cabin support structure 7, the rear cabin is connected to the rear cabin support structure 6, and the gap between the front cabin and the rear cabin is set .

[0041] The front wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com