Thickened wind turbine blade with high pneumatic performance

A wind turbine blade and performance technology, applied in the field of wind energy utilization, can solve the problems of large power peak fluctuation, large aerodynamic noise, low wind energy utilization rate, etc., and achieve the effect of high bending resistance and fatigue damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail below with reference to the accompanying drawings and examples.

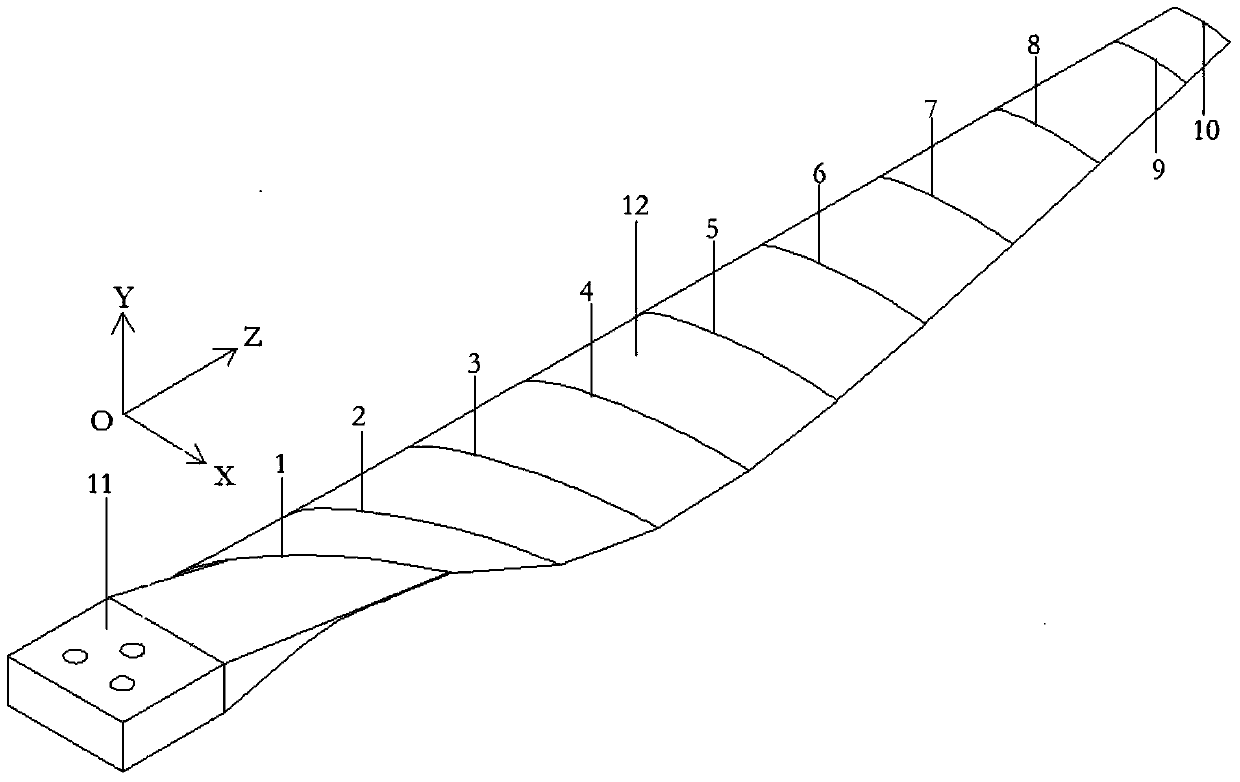

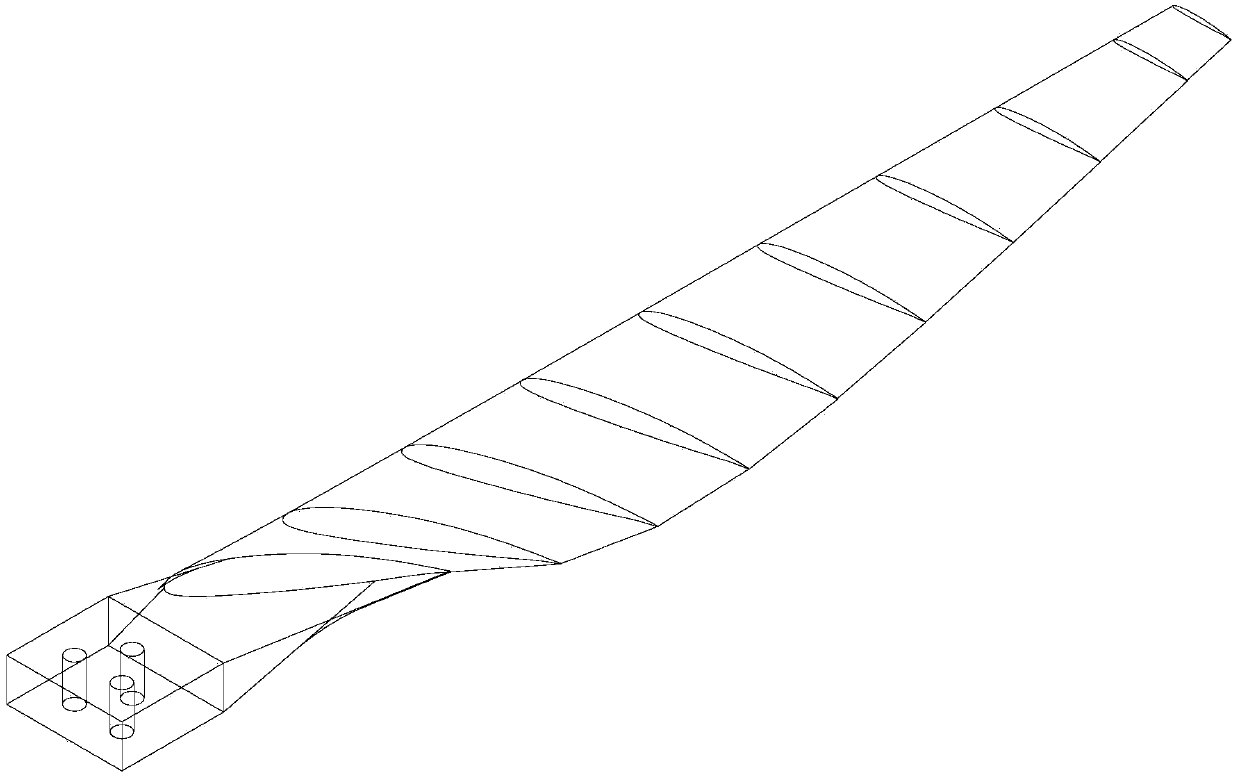

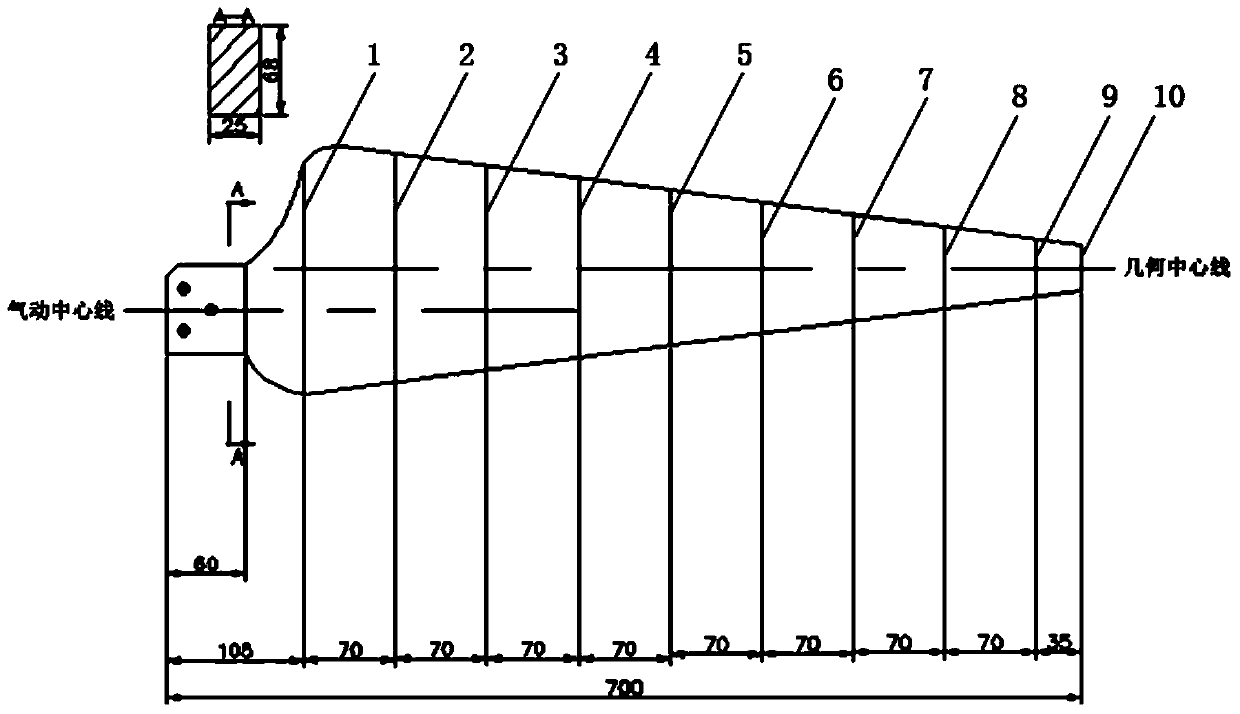

[0060] as attached figure 1 , 2 As shown in and 3, the thickened high aerodynamic performance wind turbine blade of the present invention is made up of blade airfoil 12 and blade root 11 two parts, and blade total length is 700mm, and blade airfoil part is by ten airfoil surface airfoil curve continuous smooth transitions generated, as attached Figure 4 As shown, the chord lengths corresponding to the ten airfoils are as follows: the first airfoil 1 is 193.2mm, the second airfoil 2 is 174.5mm, the third airfoil 3 is 155.9mm, and the fourth airfoil Surface 4 is 137.2mm, fifth airfoil surface 5 is 118.5mm, sixth airfoil surface 6 is 99.9mm, seventh airfoil surface 7 is 81.2mm, eighth airfoil surface 8 is 62.5mm, ninth airfoil surface The surface 9 is 43.8mm, and the tenth airfoil surface 10 is 34.5mm;

[0061] The airfoil curves of the ten airfoils are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com