Detachable axial-flow type check valve normally-open structure

A technology of axial flow and check valves, which is applied in the direction of valve shell structure, valve details, control valves, etc., can solve the problems of limited number of times, system water loss, large valve opening pressure difference, etc., and achieves easy installation and operation, Simple structure design, effect of reducing impact load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

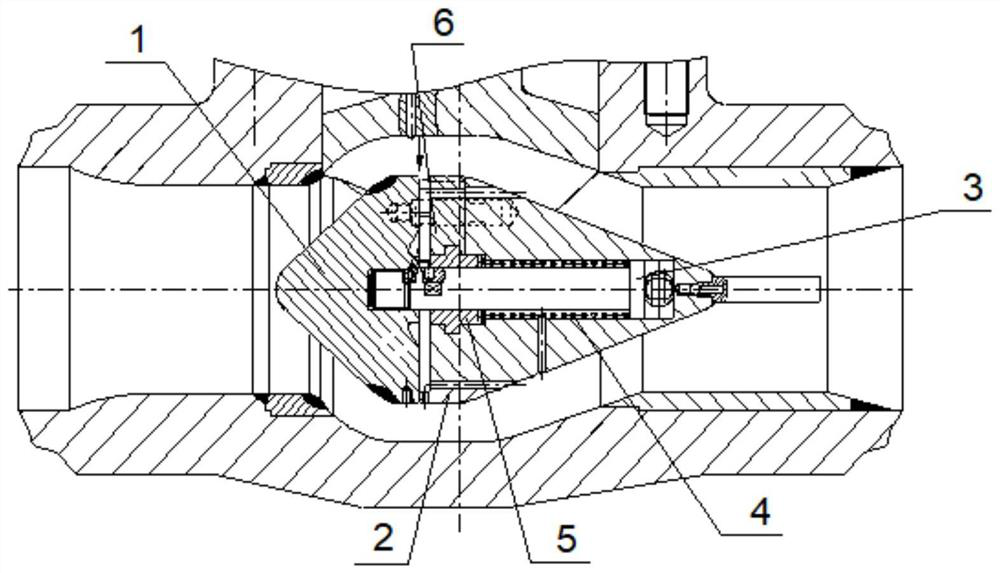

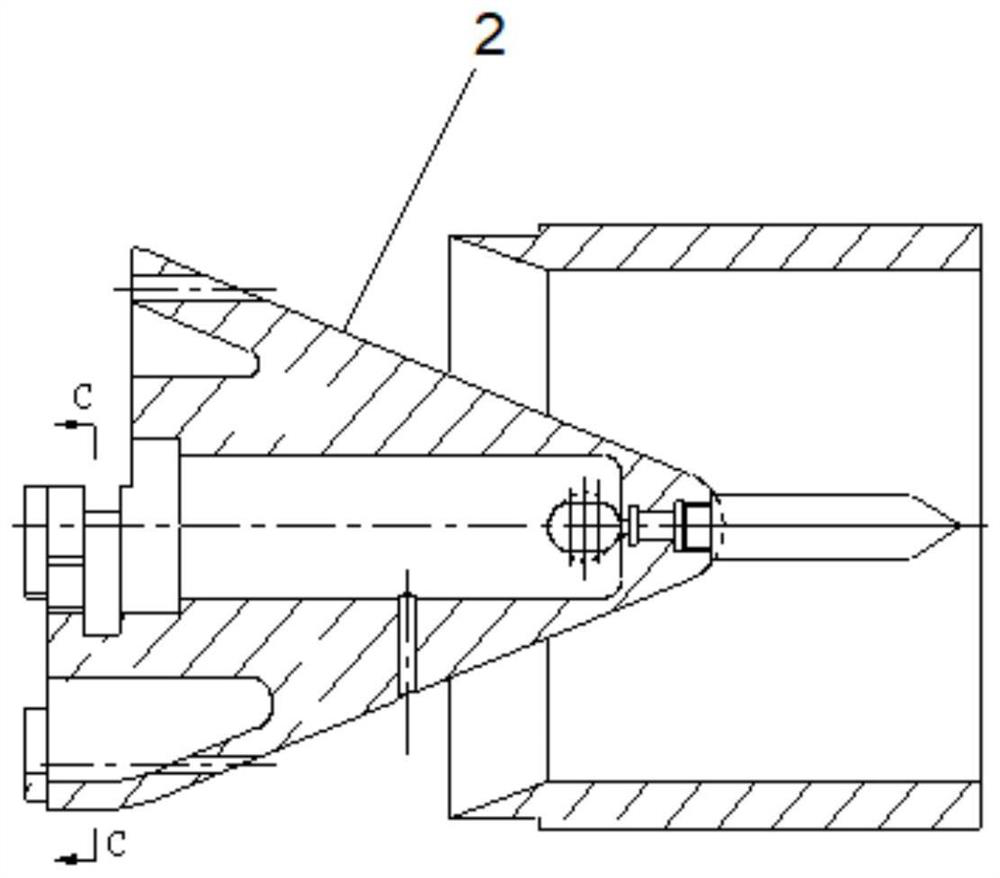

[0019] see figure 1 , a detachable axial flow check valve of the present invention with a normally open structure, including a disc 1, a fairing 2, a guide rod 3 connected to the disc, a compression spring 4, a bushing 5 and a bushing cover 6 .

[0020] The valve disc 1 and the guide rod 3 are connected by a pin shaft anti-loosening thread, and the fairing 2 is spliced by screws. The end of the guide rod 3 away from the disc 1 is provided with a spring mounting boss, on which a compression spring 4 is installed, and the end of the guide rod 3 close to the valve disc 1 is sleeved with a bushing 5, the bushing 5 The travel of the compression spring 3 is limited.

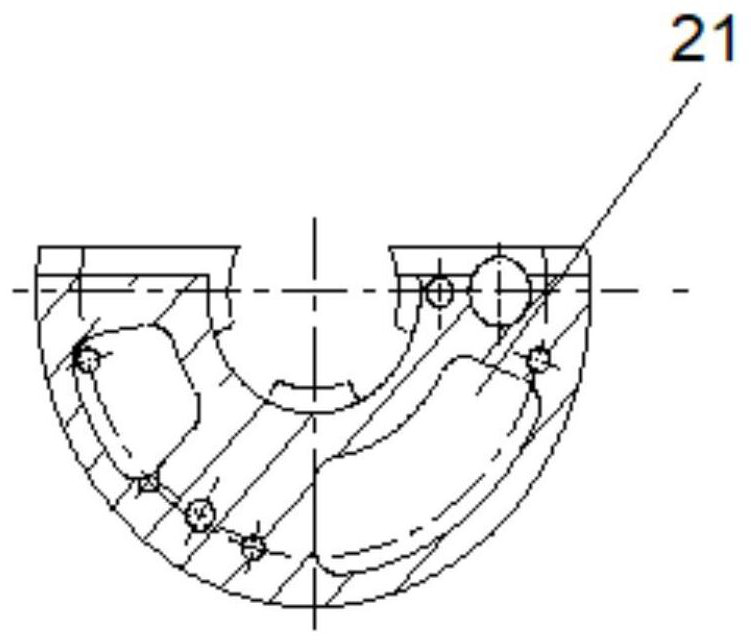

[0021] see Figure 2 to Figure 5 The outside of the shaft sleeve 5 is provided with three shoulders 51 , and the inner side of the fairing 2 is provided with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap