Range hood and cleaning method thereof

A range hood and water cleaning technology, which is applied in the direction of oil fume removal, heating methods, household stoves/stoves, etc., can solve the problems of affecting efficiency, reducing reliability, and many components, achieving good cleaning effect, improving user experience, and improving The effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

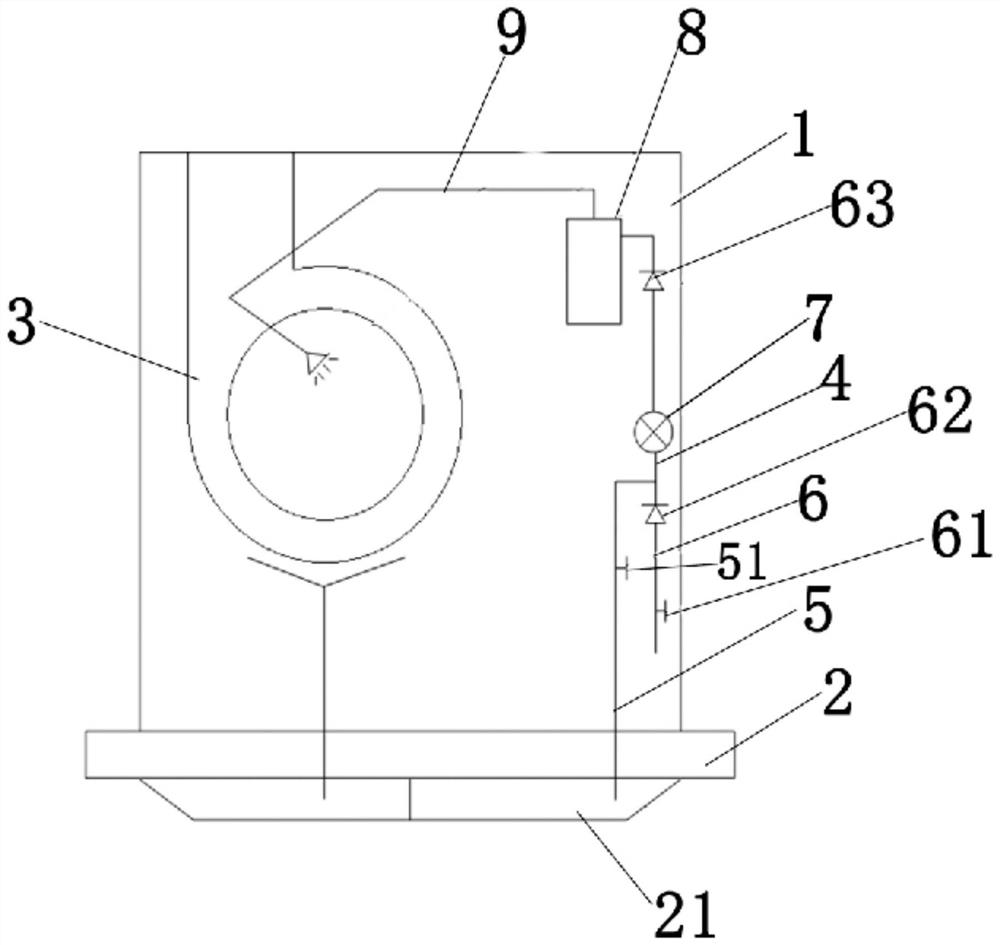

[0035] See attached figure 1 It shows a range hood of the present invention, including a box body 1 and a fume collecting hood 2, and a fan system 3 and a micro-nano bubble water cleaning device 4 are arranged in the box body 1, and the micro-nano bubble water cleaning device 4 includes a water inlet pipe 5, an air inlet pipe 6, a dissolved air pump 7, an air mixing tank 8 and a water outlet pipe 9, and the dissolved air pump 7 is installed on the air inlet pipe 6 and connected to the air mixing tank 8, the water outlet end of the water inlet pipe 5 communicates with the gas mixing tank 8, the gas outlet end of the air inlet pipe 6 communicates with the gas mixing tank 8, and the gas mixing tank at one end of the water outlet pipe 9 8 connection, the other end faces the fan system 3.

[0036] The present invention proposes a range hood, the dissolved air pump 7 works, water and air are passed into the dissolved air pump 7 through the water inlet pipe 5 and the intake pipe 6 f...

Embodiment 2

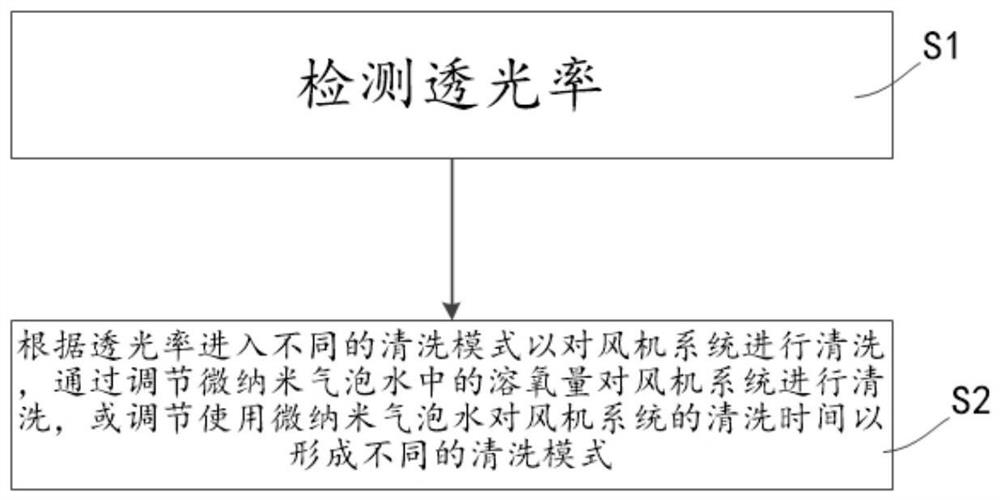

[0050] Such as figure 2 , a method for cleaning a range hood, applied to a range hood in Embodiment 1, comprising the following steps:

[0051] Step S1, using the grease detection module to detect the light transmittance through the visualization window on the fan system, and start the micro-nano bubble water cleaning device to clean the fan system;

[0052] Step S2, adjusting the cleaning mode of the micro-nano bubble water cleaning device according to the light transmittance.

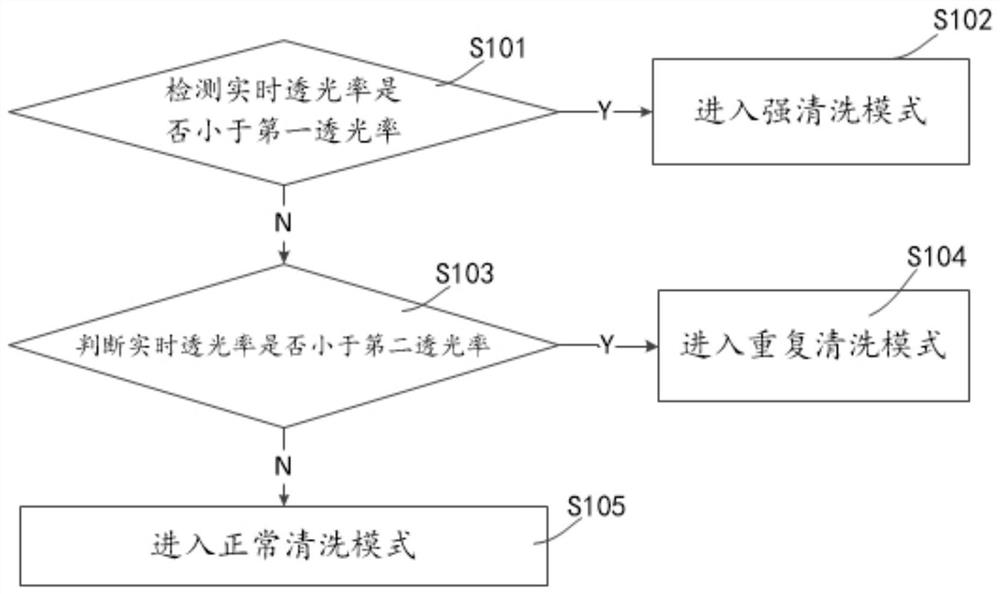

[0053] The present invention proposes a cleaning method for range hoods. By detecting the light transmittance to enter different cleaning modes to clean the fan system 3, the cleaning mode of the micro-nano bubble water cleaning device is adjusted according to the light transmittance. Different The cleaning mode includes adjusting the amount of dissolved oxygen in the micro-nano bubble water cleaning device and adjusting the cleaning time of the micro-nano bubble water cleaning device, so as to bett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com