Vertical continuous filling device

A technology of filling devices and pipe fittings, which is applied in the field of automation equipment, can solve problems such as low efficiency, and achieve the effects of fast watering speed, high degree of automation, and improved discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

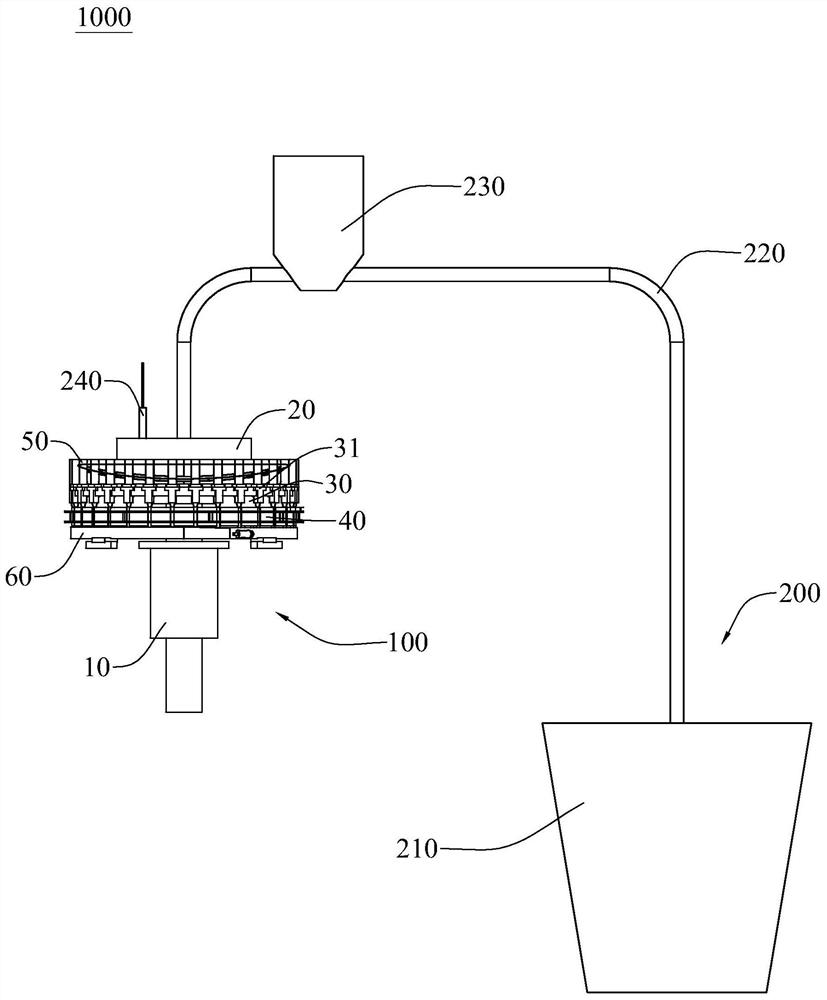

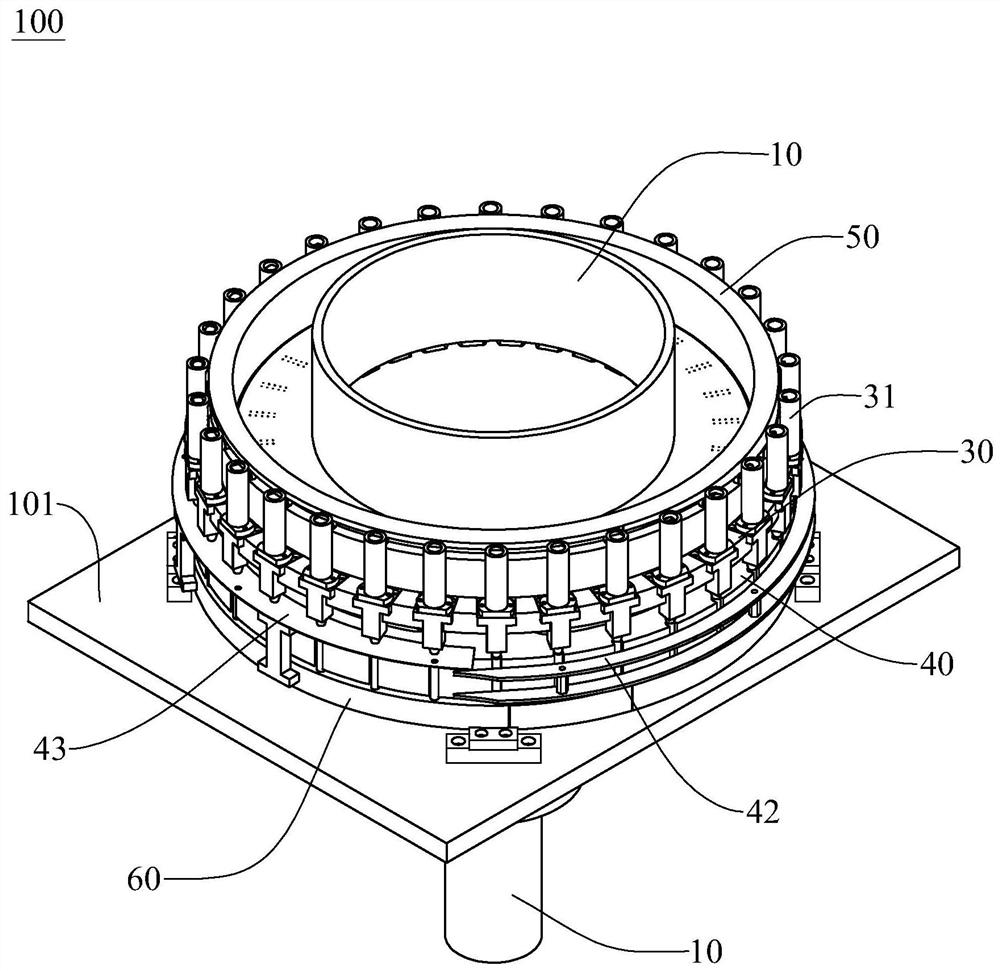

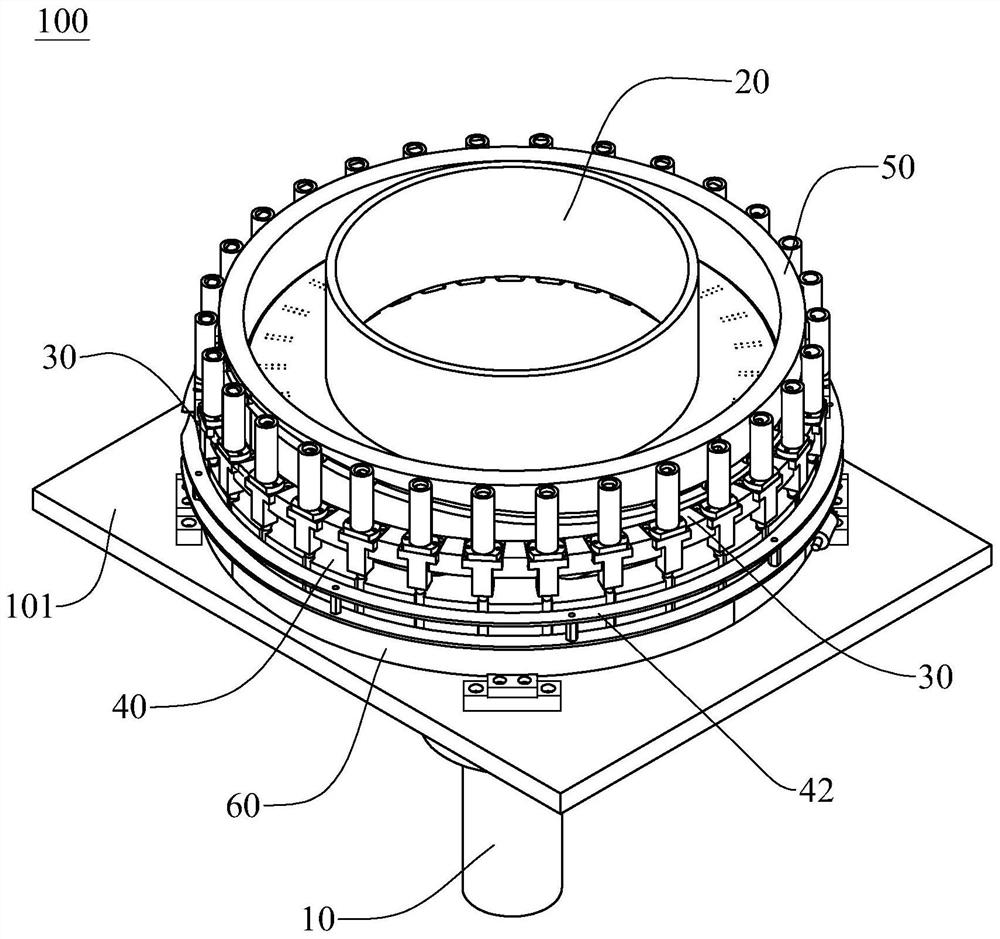

[0038] see Figure 1 to Figure 5 , the vertical continuous filling equipment 1000 includes a vertical continuous filling device 100 and a vacuum feeding system 200 . The vertical continuous filling device 100 is used for filling particles in a pipe member 102, the pipe member 102 may be a paper tube of a cigarette, and the particles may be tobacco particles. The vertical continuous filling device 100 includes a rotating mechanism 10 arranged on a frame 101 , and a bin 20 , a centrifugal disc 30 and a discharge member 40 sequentially arranged on the rotating mechanism 10 from top to bottom. The rotating mechanism 10 can drive the feed bin 20, the centrifugal disc 30 and the discharge member 40 to rotate synchronously. The rotating mechanism 10 can be electricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com