Automatic discharging ring rolling mill and using method thereof

A technology of automatic unloading and ring rolling machine, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of cumbersome installation, high price, hindering the operation space of the mandrel, etc. Achieve the effect of simple modification, low cost and convenient assembly line operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

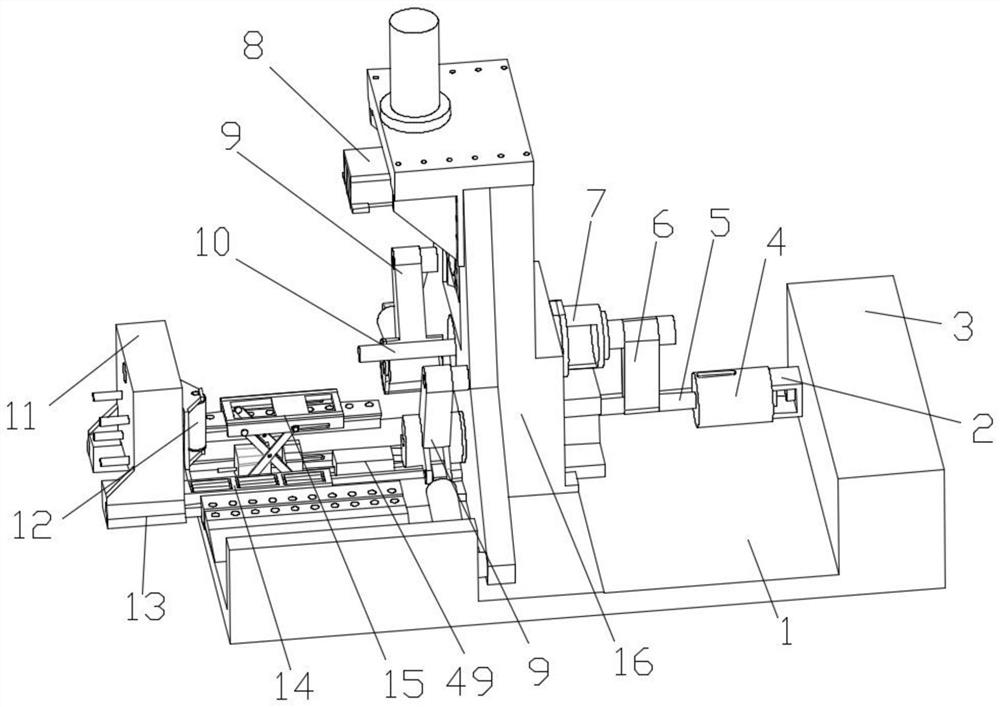

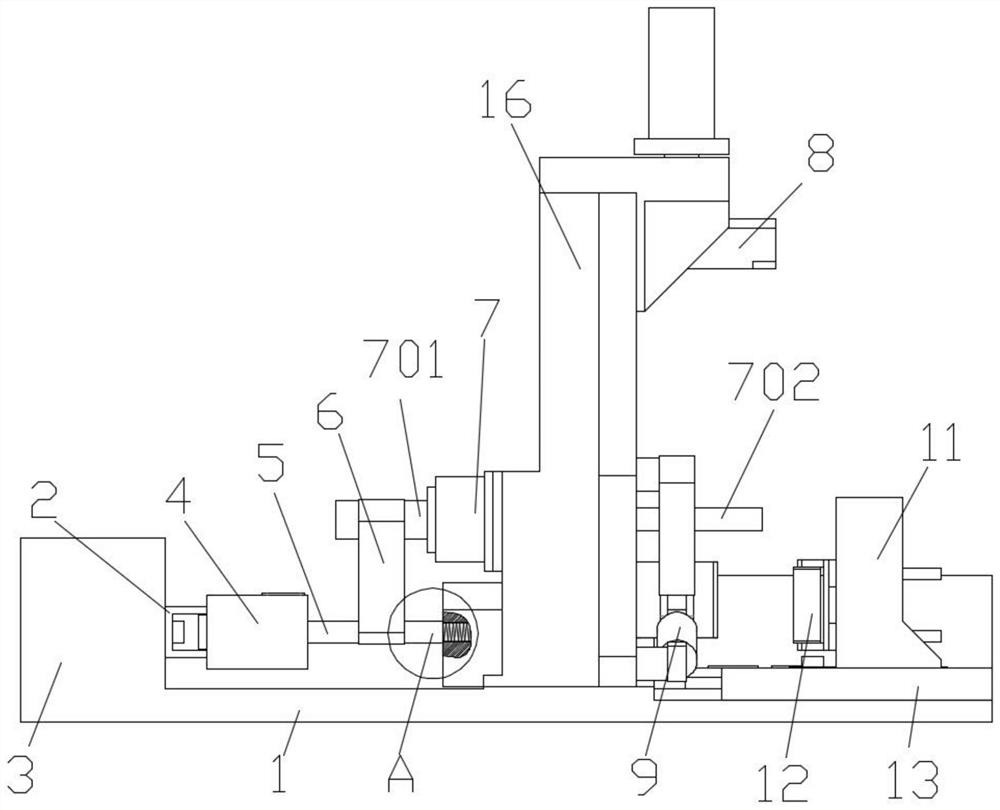

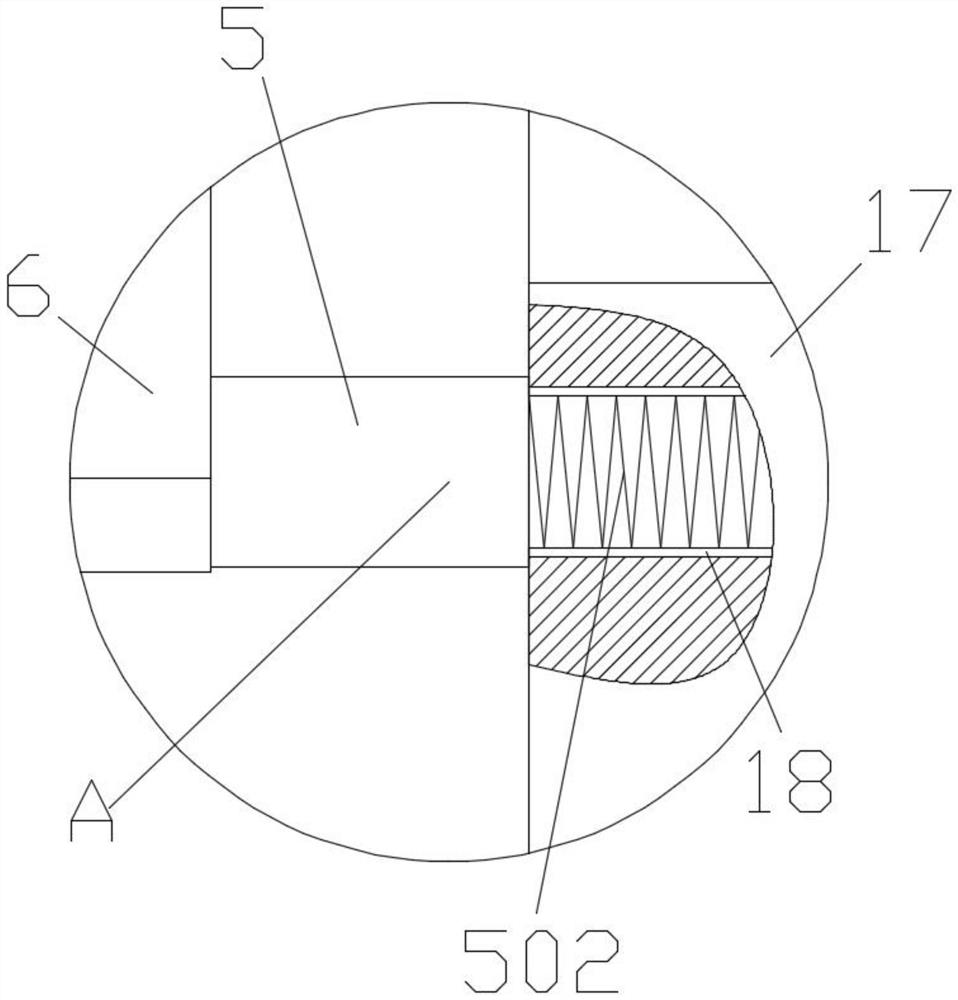

[0032] Referring to the accompanying drawings: an automatic unloading ring rolling machine in this embodiment includes a base 1, a back seat 3 fixedly connected to the rear end of the base 1 and a support plate 16 fixedly connected to the upper end of the middle part of the base 1, the left end of the back seat 3 The mounting seat 2 is fixedly connected, and the left end of the mounting seat 2 is fixedly connected with an adjustment part 4, and the left end of the adjustment part 4 is rotatably connected with a rotating shaft 5, and the outside of the rotating shaft 5 is fixedly connected with a bearing 30 at the left end and a bearing at the right end. Bearing two 34, the outer side of the first bearing 30 and the second bearing 34 is fixedly connected with a transmission part 31, the outer side of the transmission part 31 is connected with one end of the conveyor belt 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com