Efficient hot die casting machine for functional ceramic preparation

A technology of functional ceramics and hot die casting, applied in kitchen utensils, heat exchange equipment, rotors, etc., can solve the problems of superposition of smoothness, inaccurate die casting of alloy liquid, sliding offset, etc., and achieve the effect of preventing residual water mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] as attached figure 1 to attach Figure 6 Shown:

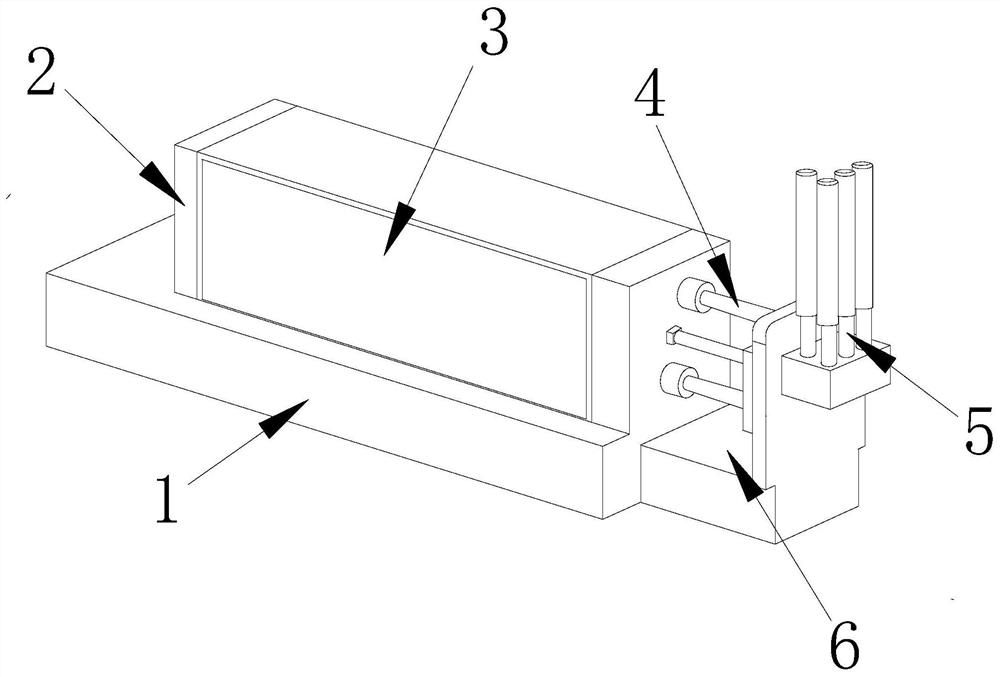

[0031] The invention provides a high-efficiency hot die-casting machine for preparing functional ceramics. Its structure includes a base 1, a working box 2, a placement door 3, a transmission column 4, a row pipe 5, and a bottom frame 6. The upper end of the base 1 is connected to the working The lower end of the box 2, the front end of the working box 2 is riveted and connected to the rear end of the placement door 3, the left end of the transmission column 4 is movably engaged with the right end of the working box 2, and the lower end of the row pipe 5 is welded and connected to the upper end of the chassis 6. The left end of the underframe 6 is fixedly connected to the right end of the base 1 .

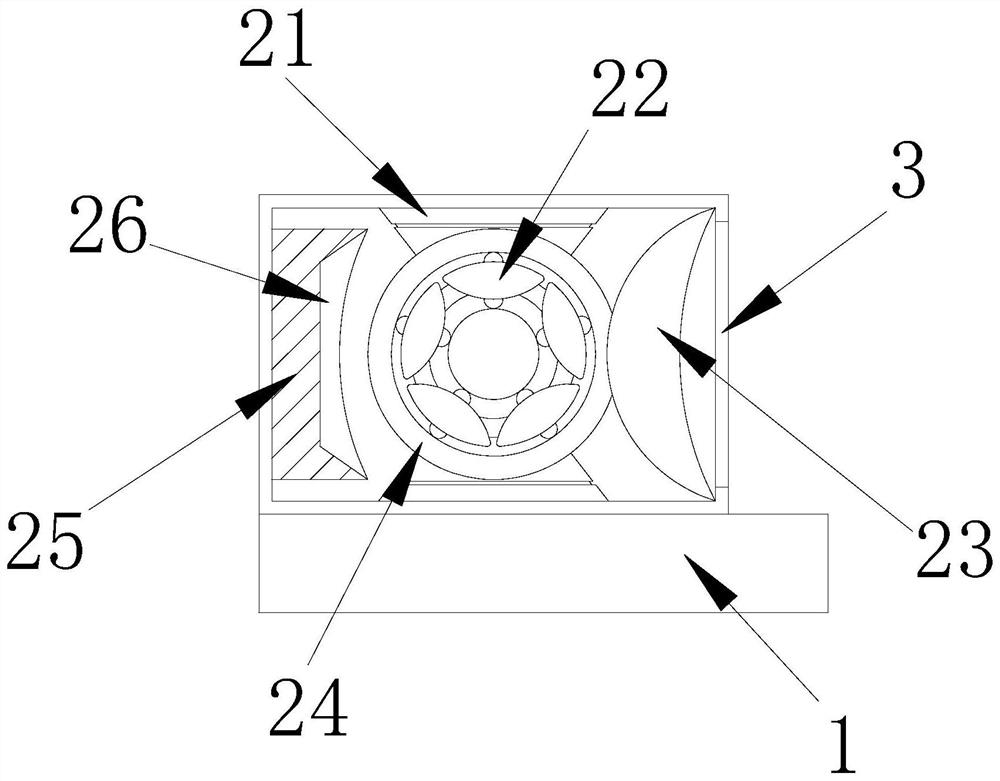

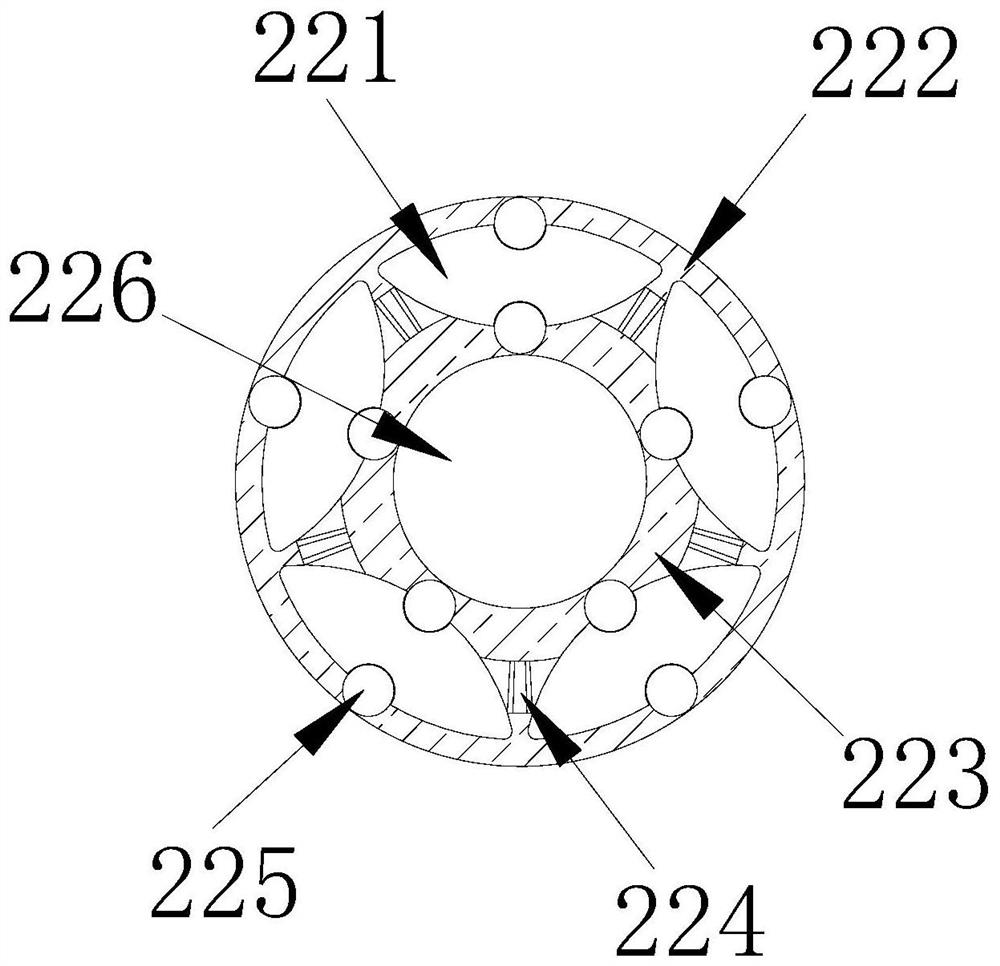

[0032] Wherein, described working box 2 is provided with fixed frame 21, fixing device 22, scraping device 23, collar 24, die-casting box 25, guide port 26, and described fixed frame 21 inner side and collar 24 outer sides ...

Embodiment 2

[0040] as attached Figure 7 To attach Figure 9 Shown:

[0041] The present invention provides a high-efficiency hot die-casting machine for preparing functional ceramics. The scraper 23 is provided with a scraper 231, a baffle 232, a spring 233, a scraper groove 234, a pressing block 235, and a stopper 236. The scraper 23 The plate 231 and the scraping groove 234 are an integrated structure, the outer side of the scraper 231 is fixed on the inner side of the pressing block 235, the outer side of the baffle plate 232 is welded to the inner side of the pressing plate 235, the outer side of the elastic plate 233 is embedded and fixed on the inner side of the baffle plate 232, The outer side of the stopper 236 is connected with the inner side of the elastic plate 233 , and the elastic plate 233 and the stopper 236 are made of rubber with elasticity, so that the ceramics will not be damaged when they enter the scraping groove 234 .

[0042] Wherein, the scraper 231 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com